Razor blade, its preparation method and application

A razor and blade technology, applied in the field of improvement of razors and blades, can solve the problems of increased blade radius, dullness, and reduced shaving effect, so as to slow down the dullness of the blade, enhance the strength of the blade, and achieve excellent shaving. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

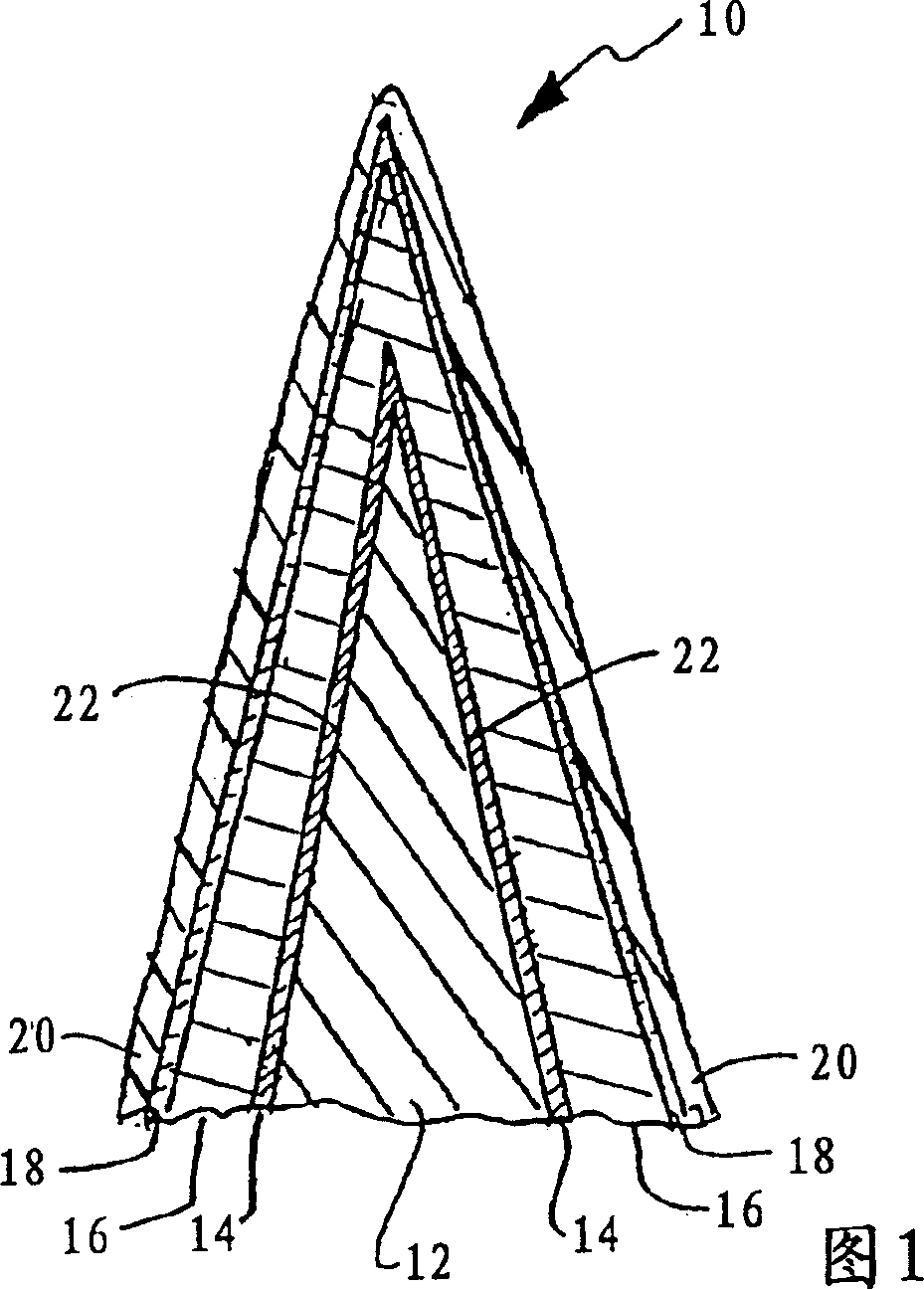

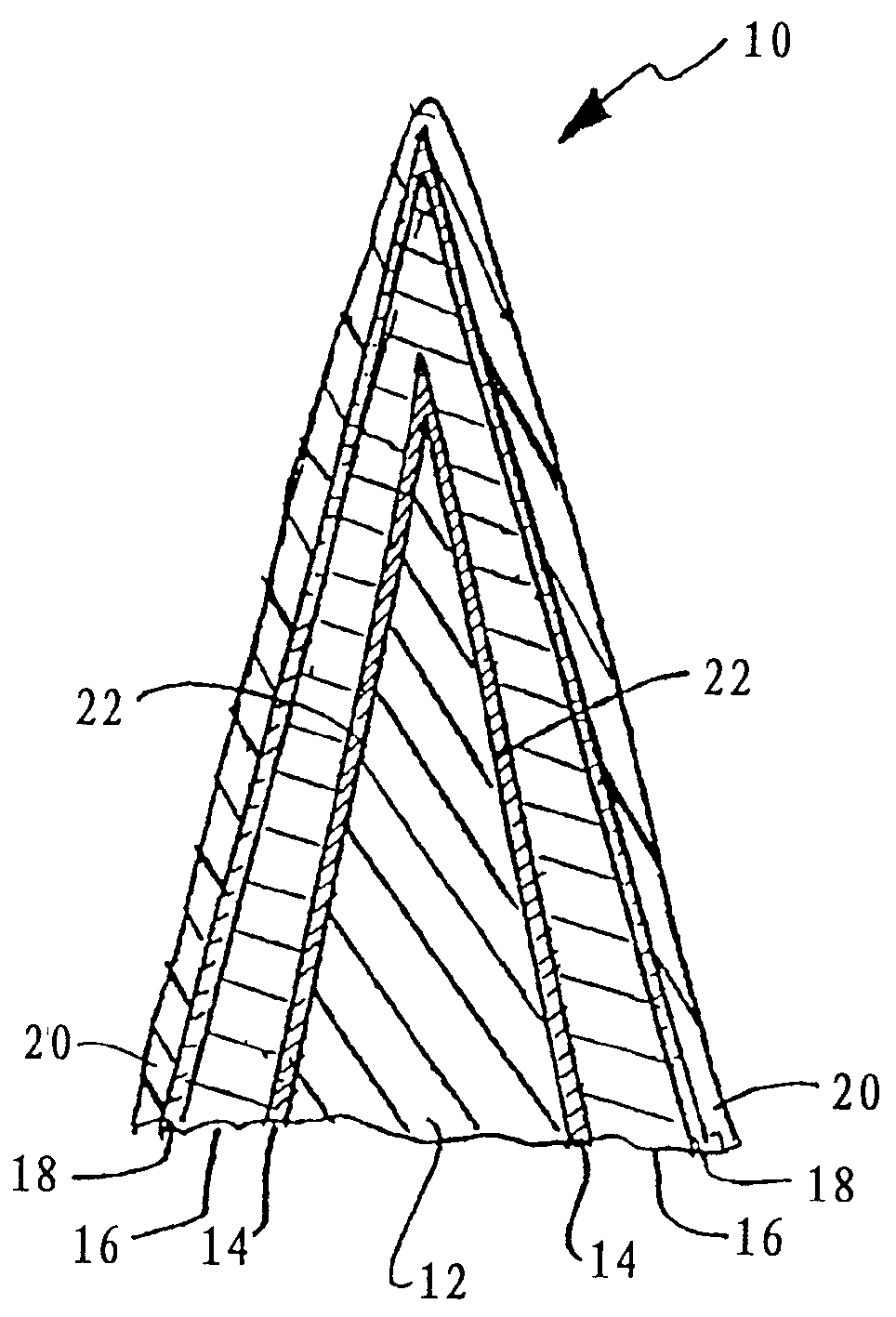

[0013] Referring to FIG. 1 , a razor blade 10 is shown comprising a substrate 12 , an inner layer 14 , a hard layer 16 , a cover layer 18 and an outermost layer 20 . Substrate 12 is generally made of stainless steel (other substrates can also be used) and is sharpened at its extreme edge to form a knife peak with a radius of less than 1000 Angstroms, preferably 200-300 Angstroms, and has a profile with sides 22 of 15-30 Angstroms. degrees, preferably an included angle of 19 degrees, measured 40 microns from the blade edge.

[0014] The inner layer 14 is used to promote adhesion of the hard coat to the substrate. Examples of suitable inner layer materials are niobium- or chromium-containing substances. The individual inner layers are made of niobium with a thickness greater than 100 Angstroms, preferably less than 500 Angstroms. The use of an inner layer of niobium is described in patent PCT92 / 03330.

[0015] The hard coat layer 16 provides improved strength, corrosion resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com