Knife tool chip breaker

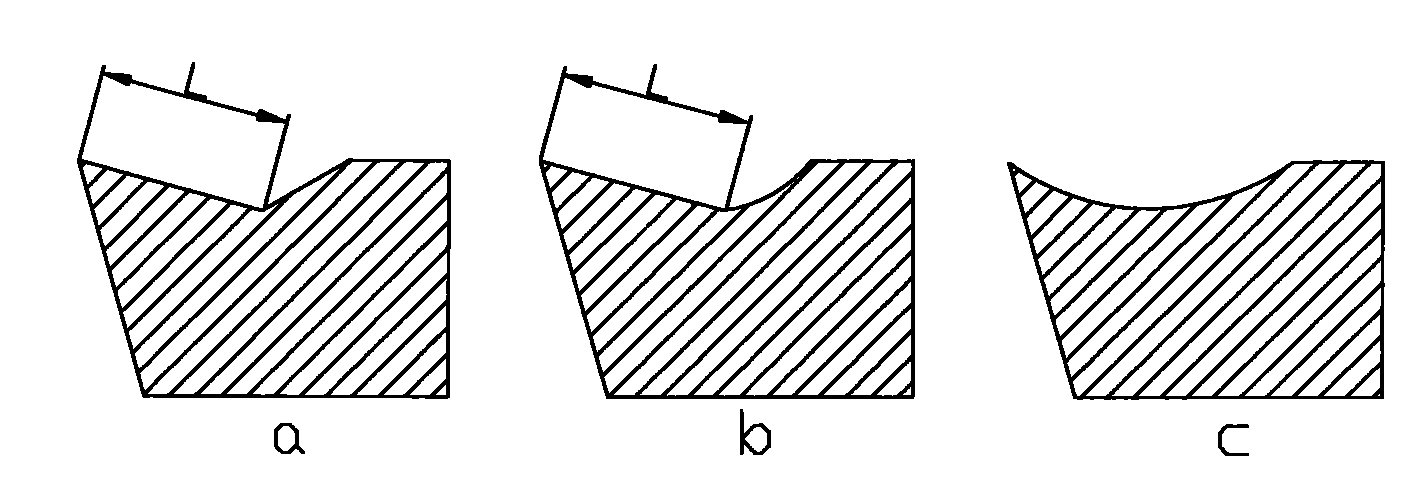

A technology of chip breaker and cutting tool, which is applied in the direction of cutting tools, manufacturing tools, and accessories of tool holders for lathes. It can solve the problems of material plasticity and elasticity that are difficult to break chips, and achieve improved chip volume and chip breaking effects. Effect of increasing chip deformation and increasing depth of cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

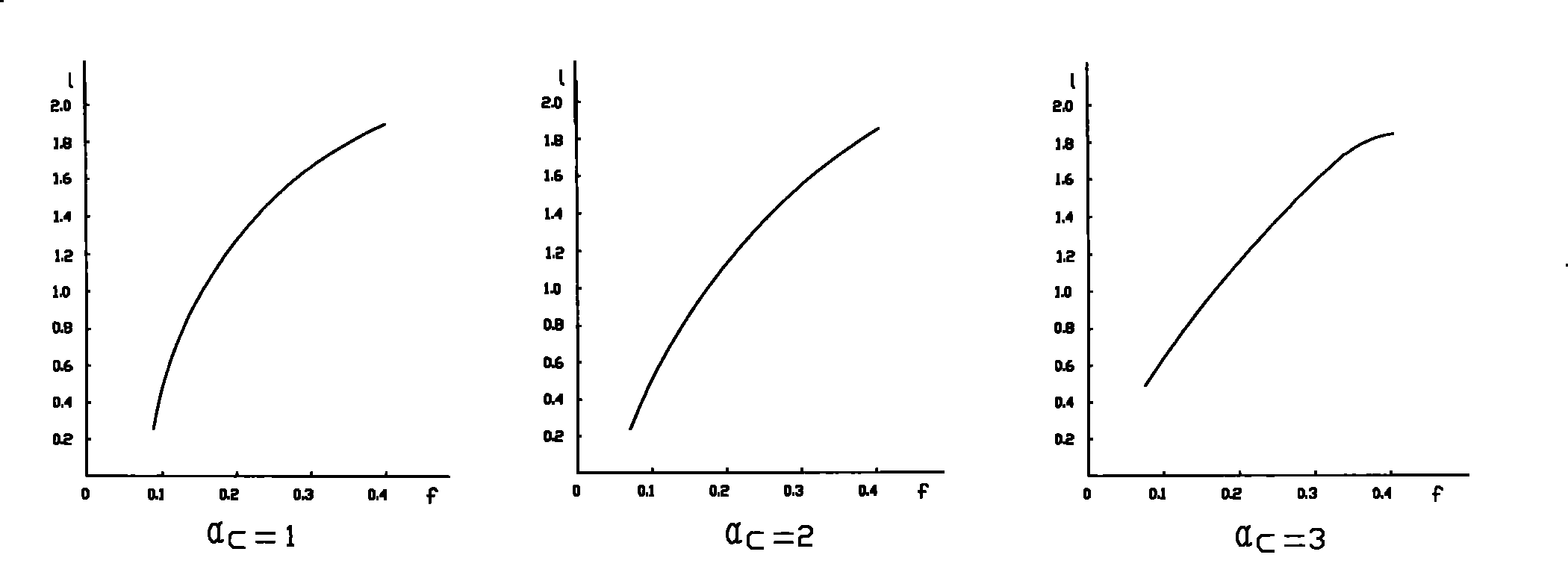

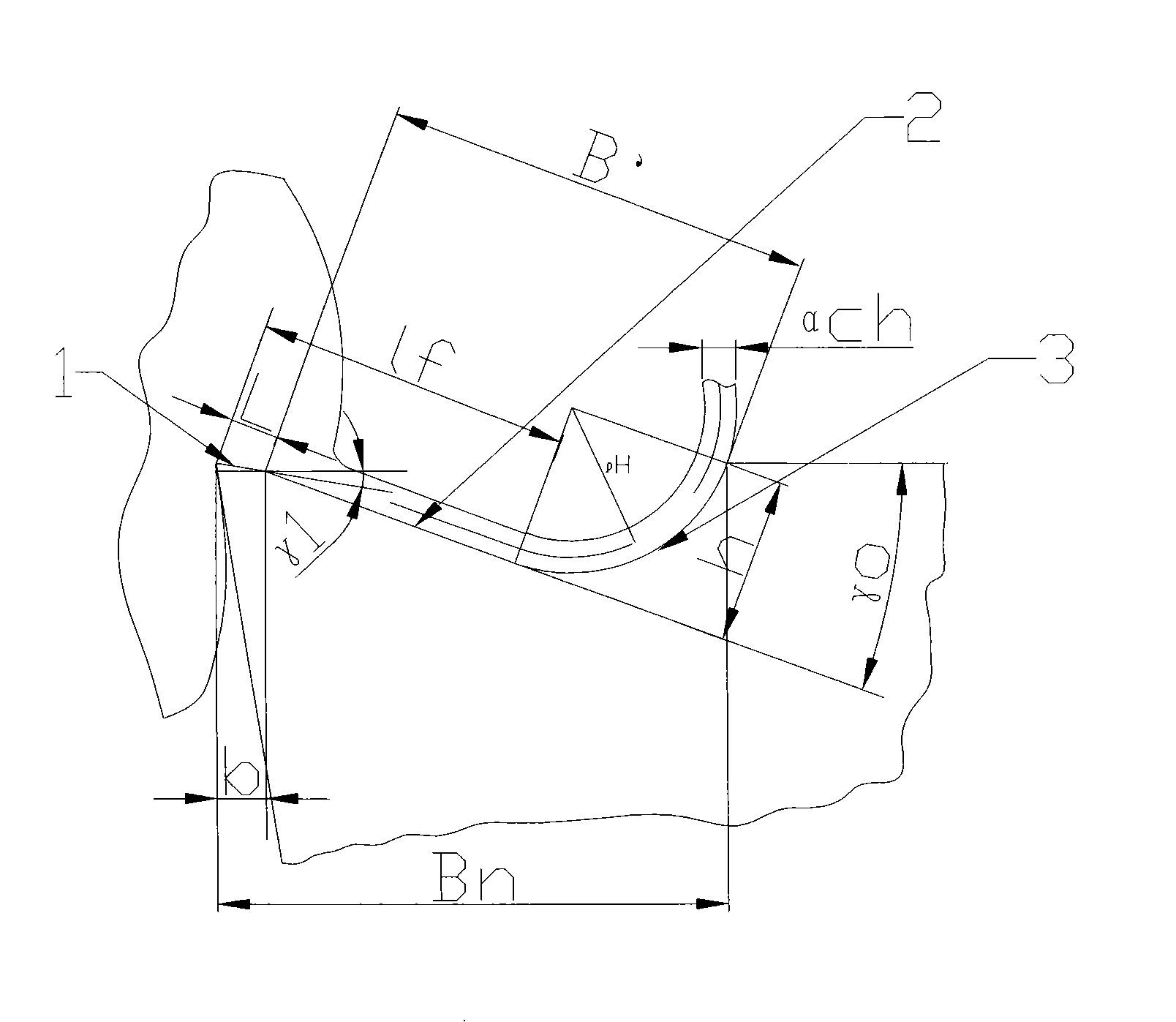

[0042] When the cutting thickness ac is less than or equal to 0.15 mm, the length of the first rake face 1 is 0.1 mm to 0.15 mm, and the rake angle of the first rake face 1 is γ 1 Take minus 5 degrees to zero degrees. The length of the second rake face 2 is not greater than one time of the cutting thickness.

[0043] Let E=2000kgf / mm 2 , σ S =62.5kgf / mm 2 ~65kgf / mm 2 , ε b =0.0063, B=720, η=04~0.5, calculate the radius of curvature ρ of the arc chip flute 3 according to the formula (2) H =1.8mm~2.3mm; at this time, the chip length is 50mm~100mm, and the chip breaking effect is good.;

Embodiment 2

[0045] When the cutting thickness ac is greater than or equal to 0.15mm but less than 0.25mm, the length of the first rake face 1 is 0.15mm, and the rake angle of the first rake face 1 is γ 1 Take 0 degrees to 5 degrees. The length of the second rake face 2 is not greater than twice the cutting thickness.

[0046] Let E=2000kgf / mm 2 , σ S =62.5kgf / mm 2 ~65kgf / mm 2 , ε b =0.0063, B=720, η=04~0.5, calculate the radius of curvature ρ of the arc chip flute 3 according to the formula (2) H =2.0mm~3.0mm; at this time, the chip length is 40mm~110mm, and the chip breaking effect is good.

Embodiment 3

[0048] When the cutting thickness ac is greater than or equal to 0.25 mm, the length of the first rake face 1 is taken as 0.2 mm, and the rake angle of the first rake face 1 is γ 1 Take 0 degrees to 5 degrees. The length of the second rake face 2 is not more than three times the cutting thickness.

[0049] Let E=2000kgf / mm 2 , σ S =62.5kgf / mm 2 ~65kgf / mm 2 , ε b =0.0063, B=720, η=04~0.5, calculate the radius of curvature ρ of the arc chip flute 3 according to the formula (2) H =2.8mm~4.1mm; at this time, the chip length is 60mm~120mm, and the chip breaking effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com