Machining method of negative chamfer of hard tooth-surface pinion cutter

A processing method and a technology of gear shaping cutters, which are applied in the field of tool processing, can solve the problems of low processing efficiency, poor precision of facets, and poor processing precision of chamfering width, etc., to prolong tool life, control blade shape errors, and improve edge quality. The effect of shape error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

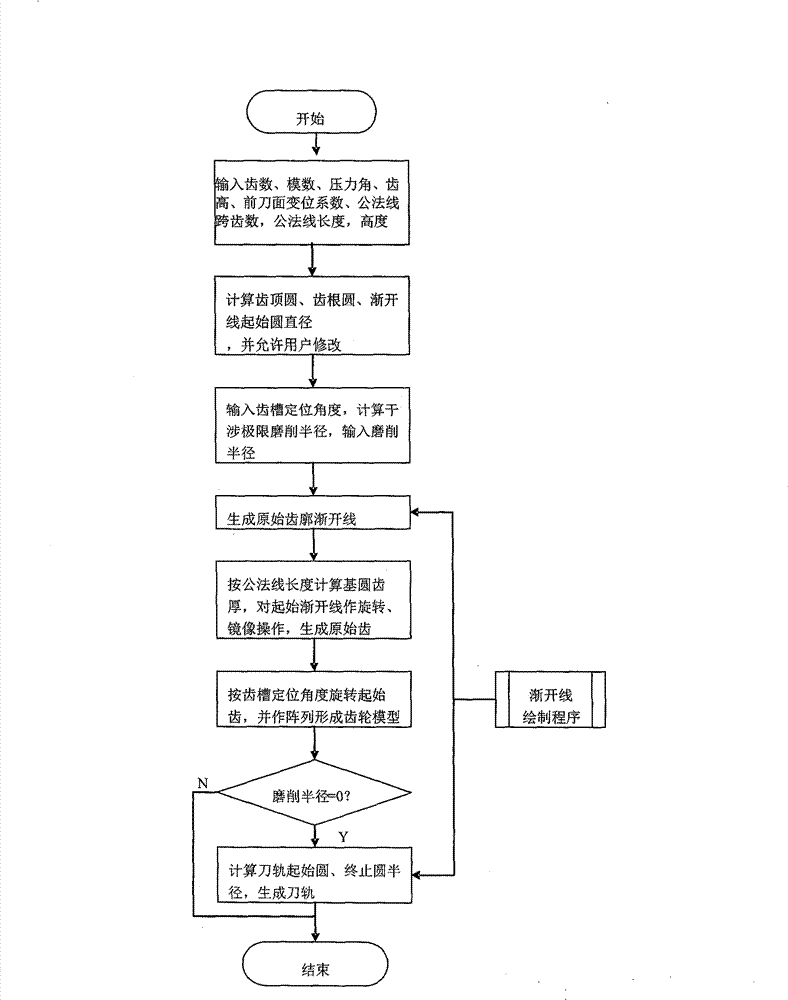

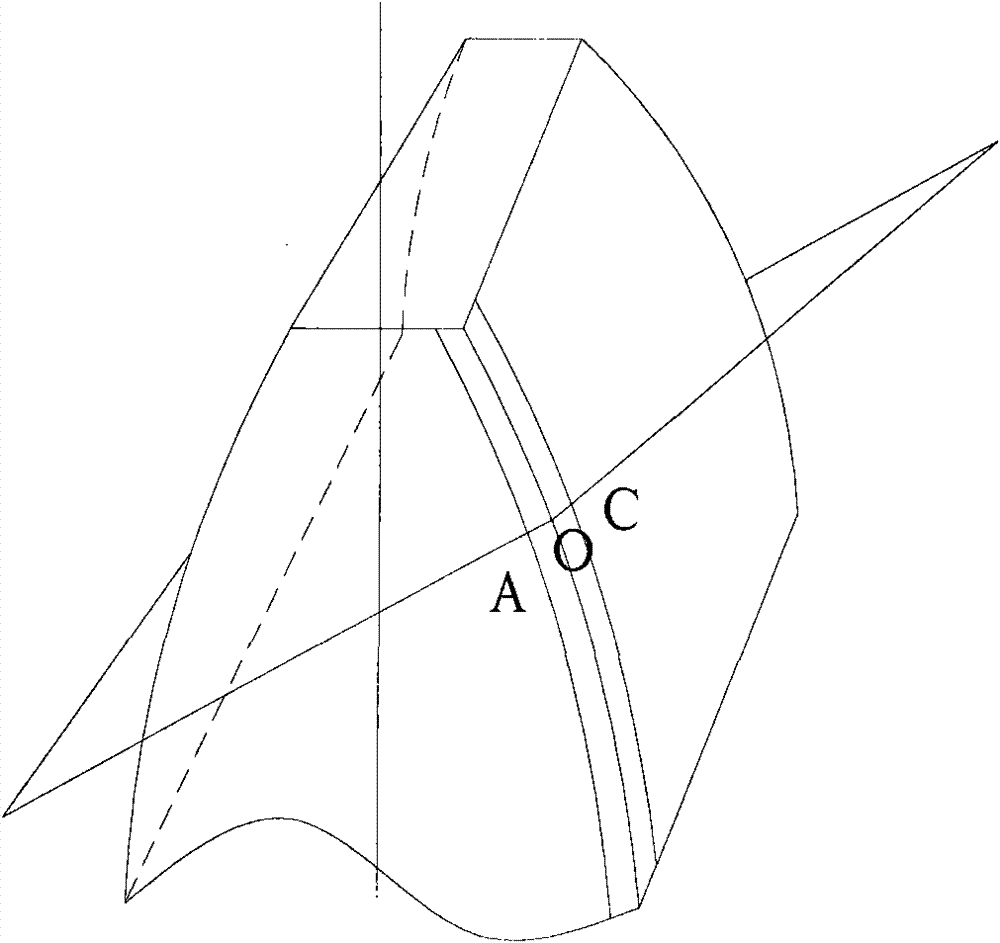

[0023] 1. Complete computer modeling and generate NC machining program

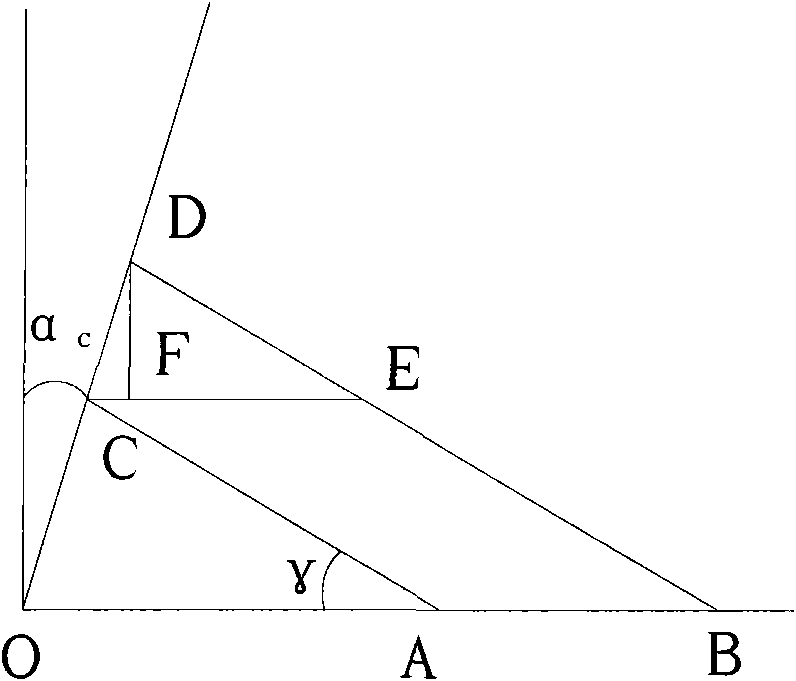

[0024] Use the computer development language to develop the modeling program of the gear shaping cutter on the 486 computer and its compatible machine, input the basic parameter information such as the module of the gear shaping cutter, the number of teeth, the pressure angle, the rake face deformation coefficient, etc., and generate the applied negative chamfering The processed gear shaper cutter model is compiled on the CNC machining center to form a CNC machining program according to the generated model.

[0025] 2. Check the parallelism of the gear shaper cutter surface

[0026] Place the gear shaper cutter flat on the workbench with the rake facing upwards. Adhere the dial gauge to the spindle of the machine tool, move the spindle roughly to the center of the gear shaper cutter, and control the z-axis of the machine tool to drop until the contact of the gauge contacts the rake face. Rotate the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com