Double-motor coaxial driven backlash elimination control system and backlash elimination control method thereof

A coaxial drive and control system technology, applied in the direction of speed adjustment of multiple motors, can solve the problems of increased debugging difficulty, complicated debugging, affecting the synchronous performance of dual motors, etc., to reduce the number of data exchanges and prevent differential vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

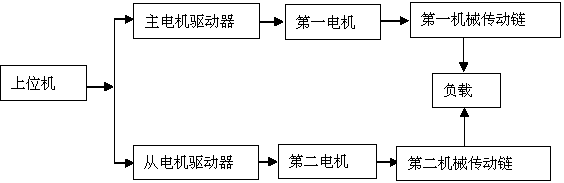

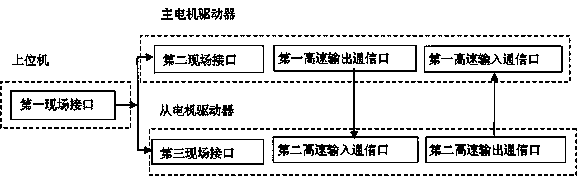

[0037] attached figure 1It is a schematic composition diagram of a dual-motor coaxial drive anti-backlash control system. It includes a host computer. The host computer can be realized by controllers such as PLC, industrial control computer or DSP. This example selects PLC as the host computer; The main motor driver, the slave motor driver, the selected master motor driver and the slave motor driver can choose a general motor driver, but must have the following three functions: 1. Speed control mode or torque control mode can be set, 2. Programmable Secondary development capability of computing, 3. Possess a high-speed communication port for master-slave synchronous control, the present invention introduces with the document "Application of 9300 Standard Servo Controller on Gingering Machine" (Document Textile Machinery, May 2007) The universal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com