Structure for mounting pump tower of lng storage tank and manufacturing method thereof

一种液化天然气、制造方法的技术,应用在泵塔设置结构体领域,能够解决降低周边空间利用率、管道固定结构和固定作业复杂、泄漏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The embodiments described below are provided as examples in order to fully convey the idea of the present invention to those skilled in the art to which the present invention pertains. The present invention is not limited to the examples described below, and can be embodied in other forms. In order to clearly illustrate the present invention, parts irrelevant to the description are omitted in the drawings, and the width, length, thickness, etc. of the constituent elements may be shown enlarged in the drawings for convenience. The same reference numerals denote the same constituent elements throughout the specification.

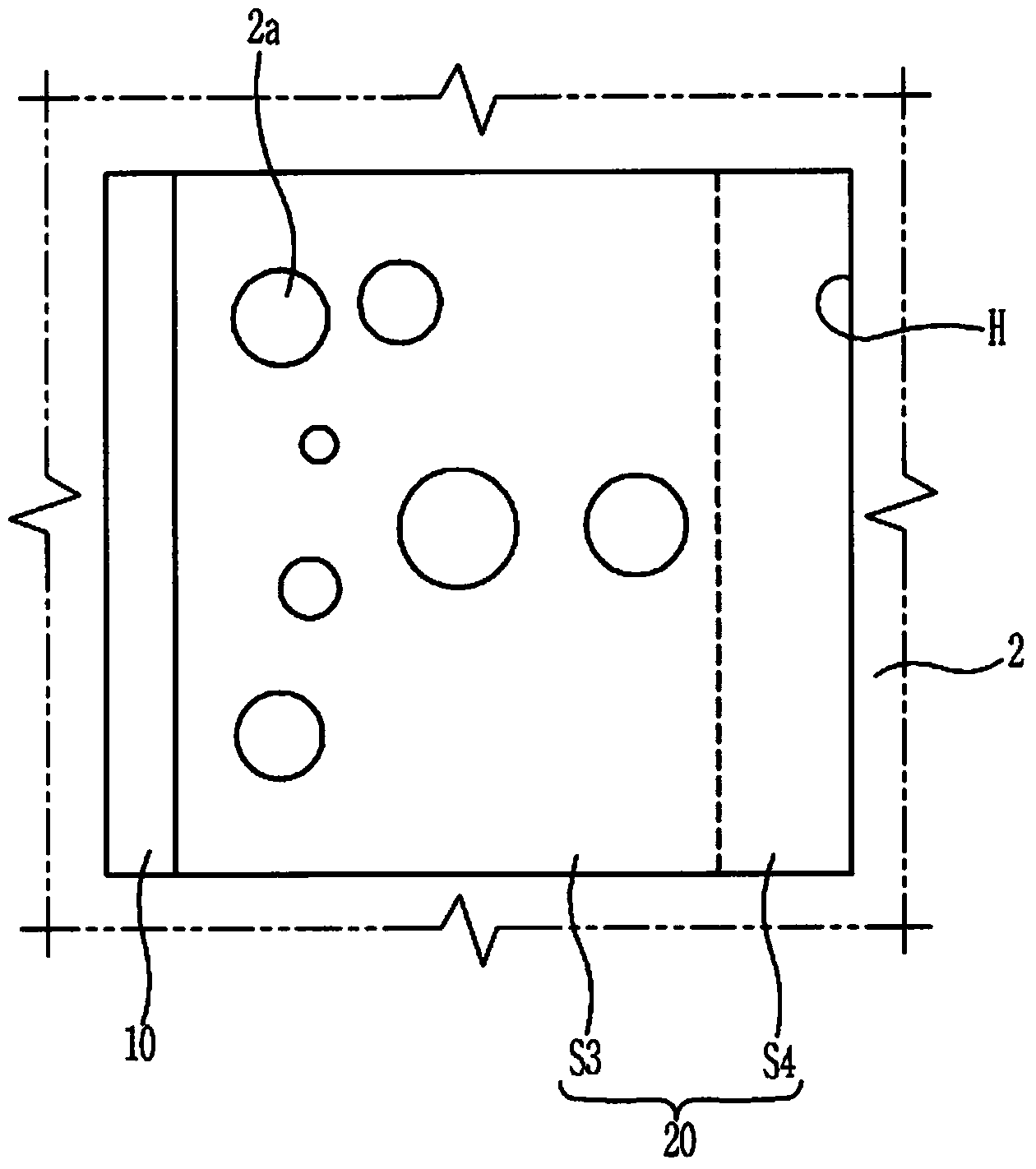

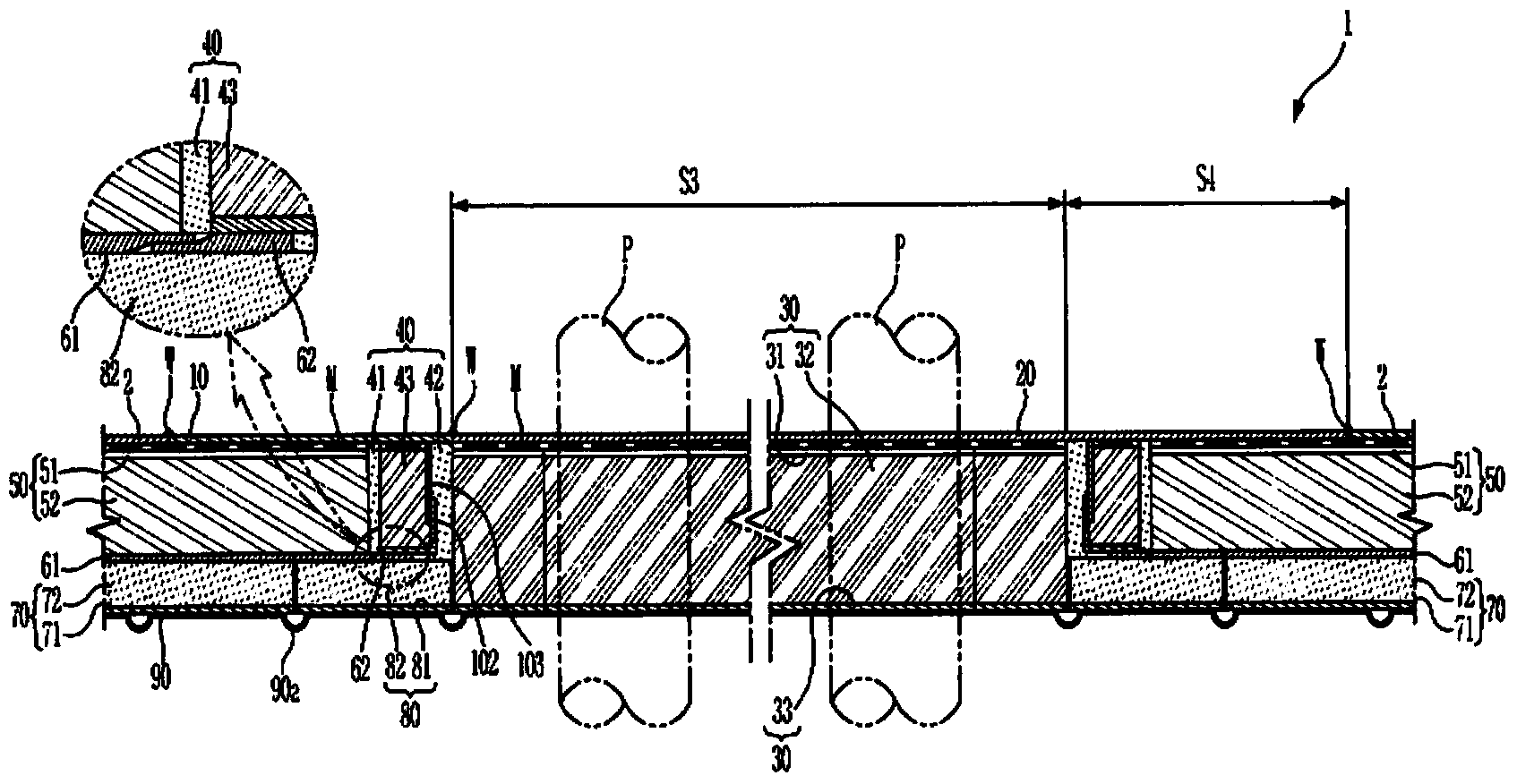

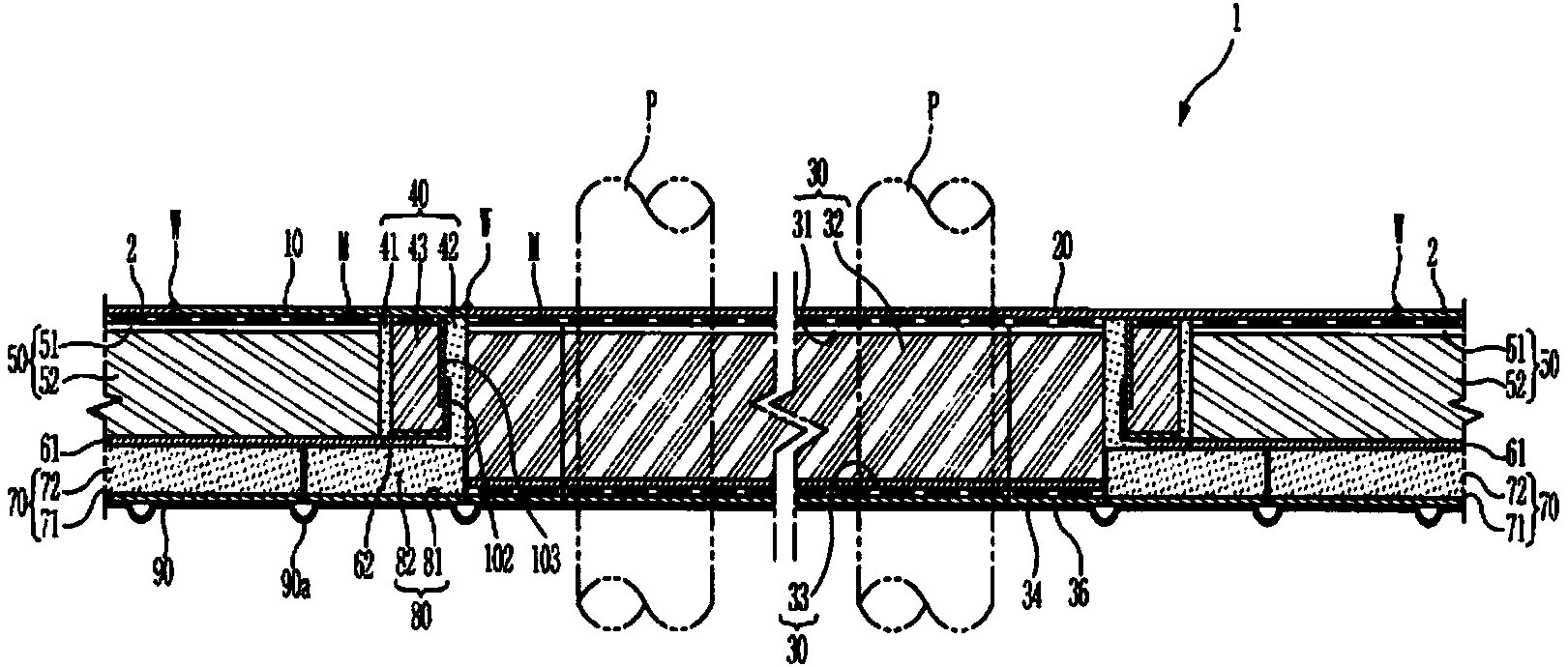

[0038] figure 1 It is a plan view showing the pump tower installation structure of the liquefied natural gas storage tank according to the first embodiment of the present invention. and, figure 2 is said figure 1 Cross-sectional view of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com