Method and apparatus for hot-dip metal coating of metal strip

一种金属涂层、金属带的技术,应用在对表面涂布液体的装置、金属材料涂层工艺、热浸镀工艺等方向,能够解决气体消耗、喷嘴梁金属带间隔大等问题,达到低消耗、最佳过程稳定性、小受干扰程度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

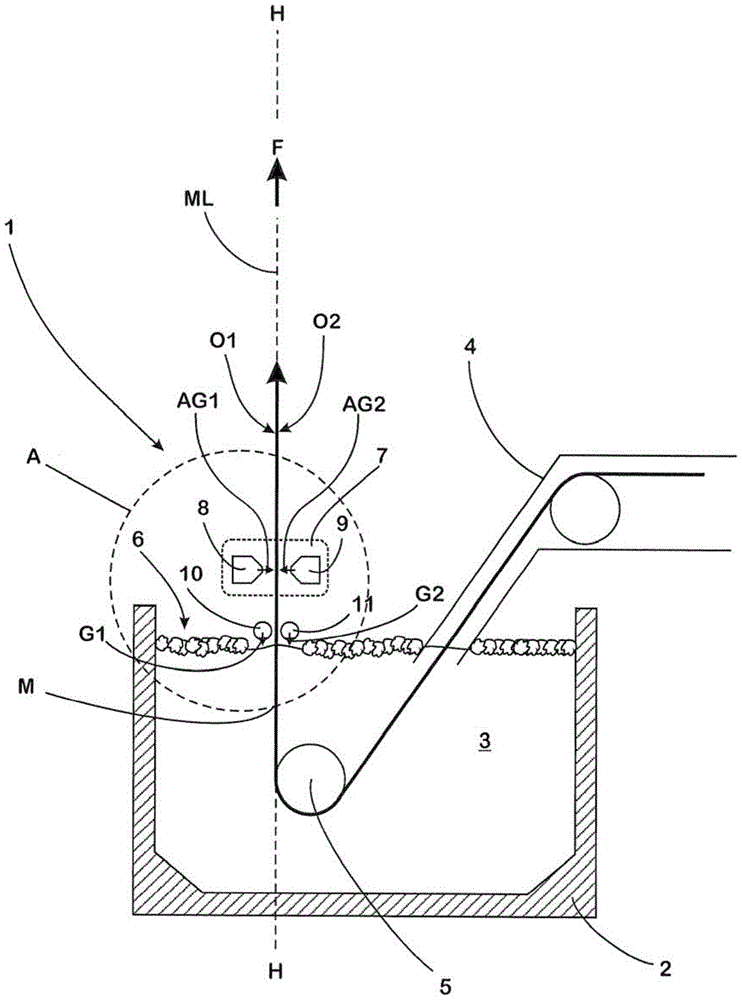

[0071] The device 1 for the hot-dip coating of metal strip M comprises a molten bath 3 filled in a boiler 2 into which the metal strip M to be coated, heated in a known manner beforehand to a sufficient immersion temperature, enters this molten bath via a tuyere branch 4, where The metal strip is, for example, a cold-rolled steel strip made of corrosion-sensitive steel.

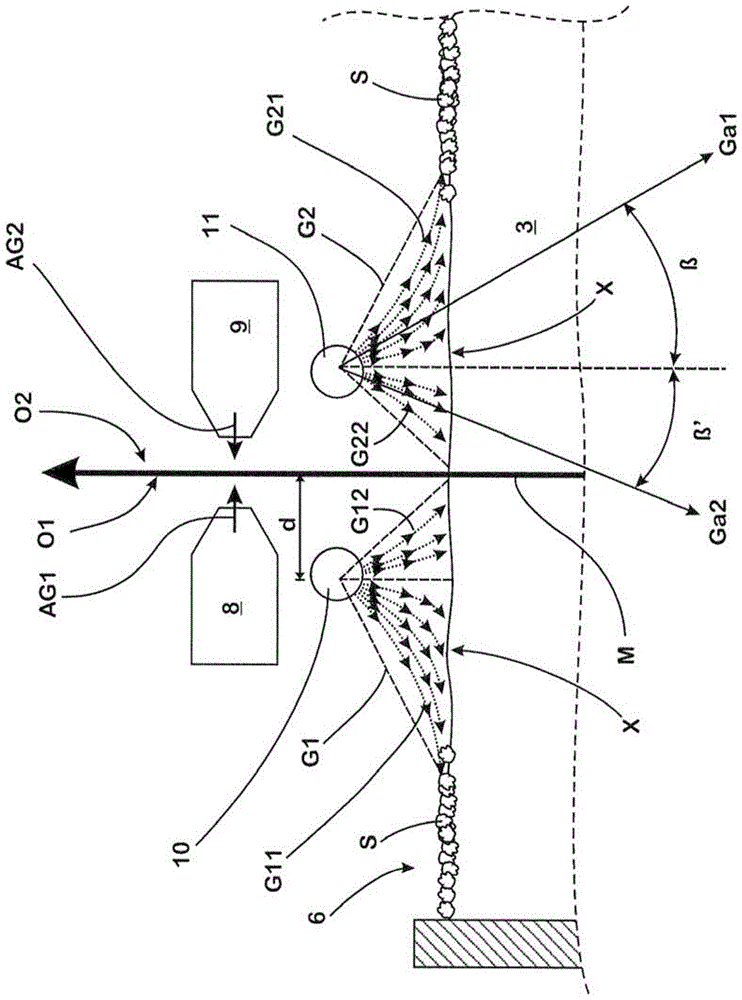

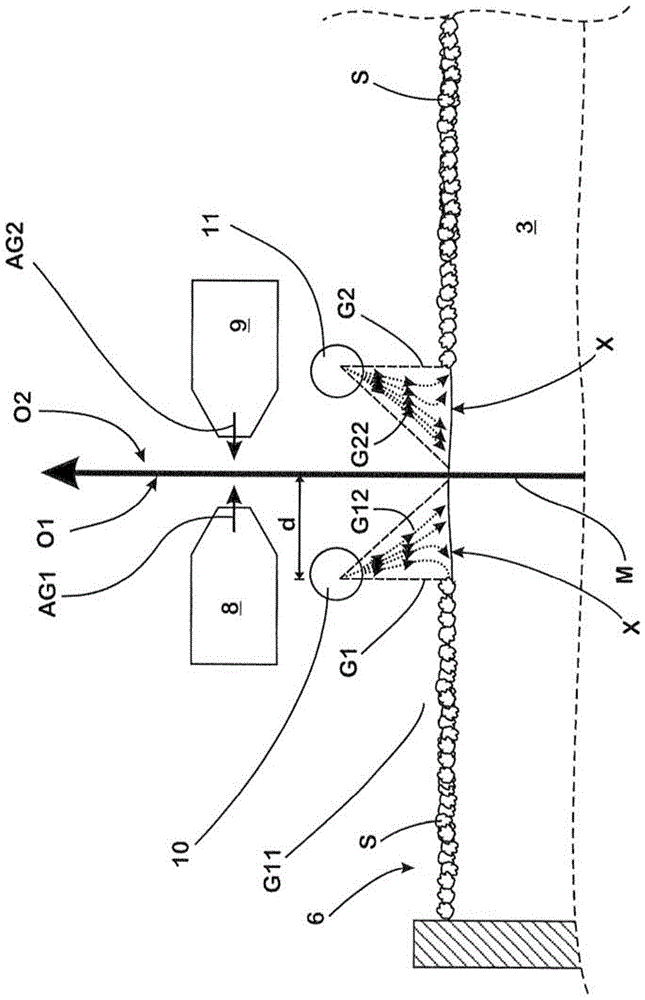

[0072] In the molten bath 3 , the metal strip M is deflected on guide rollers 5 in such a way that it leaves the molten bath 3 in the vertical direction of transport F. Therein, the metal strip M leaving the molten pool 3 passes through a stripping device 7 arranged at a distance above the surface 6 of the molten pool 3 . The stripping device here comprises stripping nozzles 8, 9 formed as slit nozzles, wherein one stripping nozzle directs the stripping air flow AG1 at the surface O1 of the metal strip M, which surface is between the longitudinal edges of the metal strip M. and another stripping nozzle direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com