Automatic sorting method and production line for large-scale multi-variety mixed-match underwear

A multi-variety and underwear technology, applied in sorting and other directions, can solve the problems of time-consuming, labor-intensive, slow speed, and low work efficiency, and achieve the effects of reducing production costs, ensuring production quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

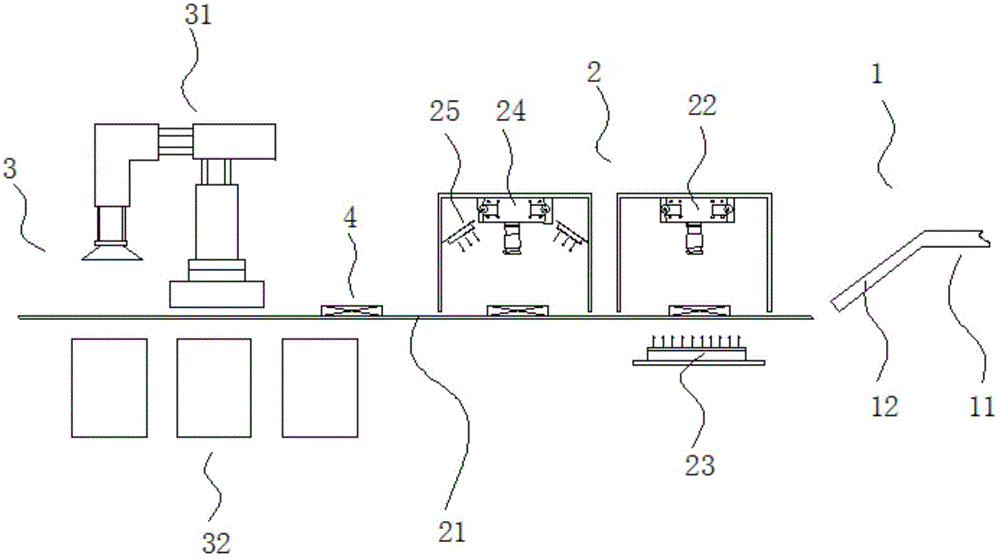

[0028] see Figure 1 to Figure 2 , the large-scale multi-variety mix-and-match underwear automatic sorting method provided by the present embodiment, it comprises the following steps:

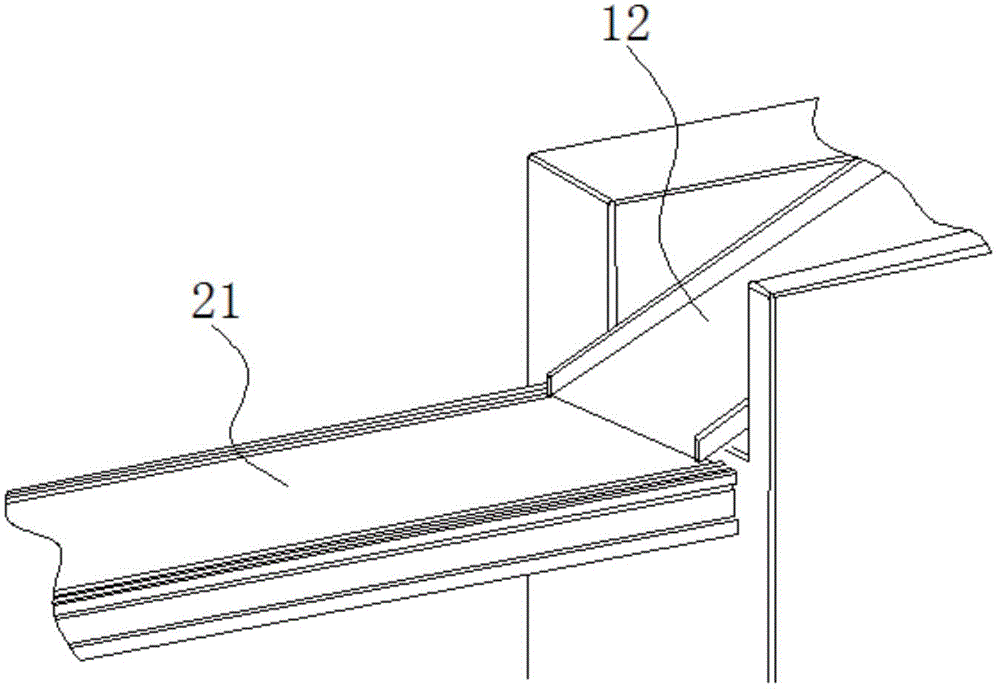

[0029] 1) Set up a feeding work area 1 to straighten out several varieties of underwear, spread them flat and face up, and then send them to the sorting work area 2; the feeding work area 1 includes a temporary storage point and a separation point. The temporary storage point is provided with a vibration plate 11, and the separation point is provided with a guide groove 12. One end of the guide groove 12 is connected with the vibration plate 11, and the other end is connected with the transparent conveying belt 21 of the sorting work area 2; Only one worker is needed, who is responsible for ensuring the normal operation of the feeding work area and sorting out the materials.

[0030] 2) A sorting work area 2 is set up, and the sorting work area 2 includes a transparent conveyor belt 21, an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com