Control method for preventing tension measuring roller from slipping relative to continuous rolling strip

A control method and technology for measuring rolls, applied in the field of metal pressure processing, can solve problems such as slippage, and achieve the effect of improving the yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

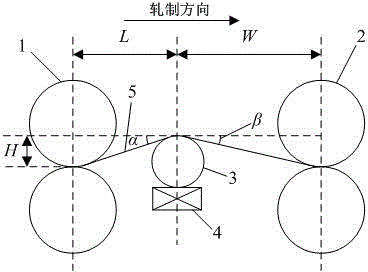

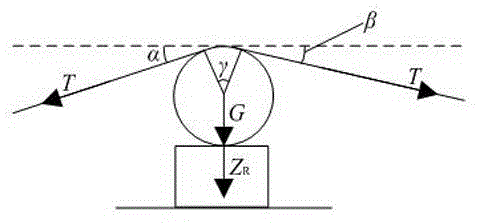

[0078] Set the distance between the center line of the tension measuring roll and the center line of the work roll of the previous frame as 1900mm; the distance between the center line of the tension measuring roll and the center line of the work roll of the next frame is 3600mm; The vertical distance of the line is 200mm; the self-weight of the tension measuring roller is 200kg; the preset tension value between two racks is 12000N; the friction coefficient between the strip and the surface of the tension measuring roller is 0.15. Then the angle between the strip and the horizontal line between the previous frame and the tension measuring roller for:

[0079]

[0080] Then the angle between the strip and the horizontal line between the latter frame and the tension measuring roller for:

[0081]

[0082] Wrap angle formed between strip and tension measuring roller for:

[0083]

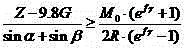

[0084] Under the condition that there is no contact between the strip and the tensi...

Embodiment 2

[0097] Set the distance between the center line of the tension measuring roll and the center line of the work roll of the previous frame as 1900mm; the distance between the center line of the tension measuring roll and the center line of the work roll of the next frame is 3600mm; The vertical distance of the line is 200mm; the self-weight of the tension measuring roller is 200kg; the preset tension value between two racks is 60000N; the friction coefficient between the strip and the surface of the tension measuring roller is 0.11. Then the angle between the strip and the horizontal line between the previous frame and the tension measuring roller for:

[0098]

[0099] Then the angle between the strip and the horizontal line between the latter frame and the tension measuring roller for:

[0100]

[0101] Indicates that the actual tension value at this moment has reached the preset value, namely .

[0102] Wrap angle formed between strip and tension measuring roller...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com