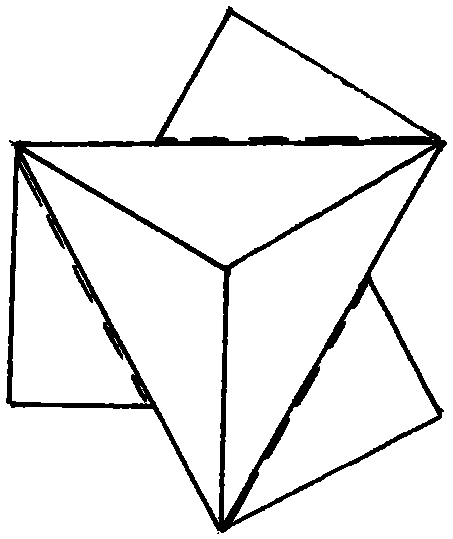

Three-dimensional plug-in triangular parts

A technology of three-dimensional shape and equilateral triangle, which is applied in the direction of cardboard objects, etc., can solve the problems of weak connection, loose connection of two triangles, and easy deformation, etc., and achieve the effect of novel design, easy manufacture of parts, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

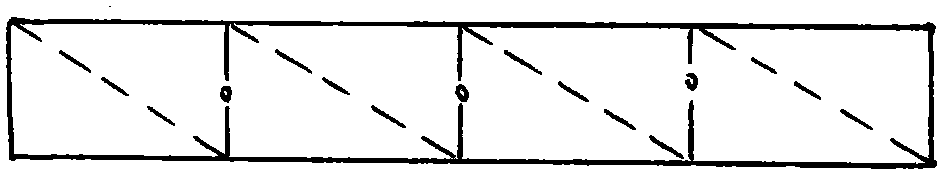

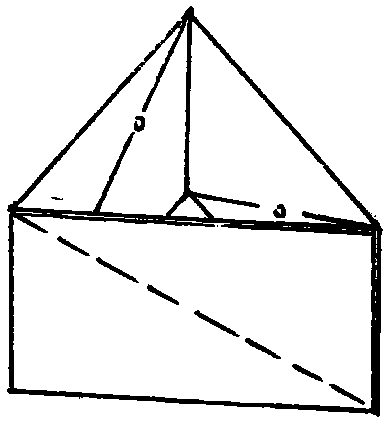

[0025] Triangular parts plugged into a three-dimensional shape, which is formed by plugging together 20 identical parts from part 1, part 2...part 20; the dotted line is used to indicate the positive fold line of the front half, that is, when folding, the front side of the paper and the front side are attached; the solid line The circle indicates the anti-folding line of reverse-folding, that is, when folding, the reverse side of the paper and the reverse side stick together; the arrow line indicates the indicator line of the insertion direction, the dotted part of the arrow line indicates the inserted part, and the solid line part of the arrow line indicates that it is not inserted part;

[0026] Take a rectangular paper that is horizontally long and vertically wide, and make three vertical fold lines perpendicular to the long side of the rectangular paper, and divide the rectangular paper into four small rectangles, namely, from left to right, the first small rectangle, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com