Wallpaper Printing System

A printing and wallpaper technology, applied in the direction of winding strips, machining/deformation, thin material processing, etc., can solve the problems of too long feeding length, weak printing pressure, etc., achieve smooth water flow, increase cooling speed, speed up The effect of loop speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

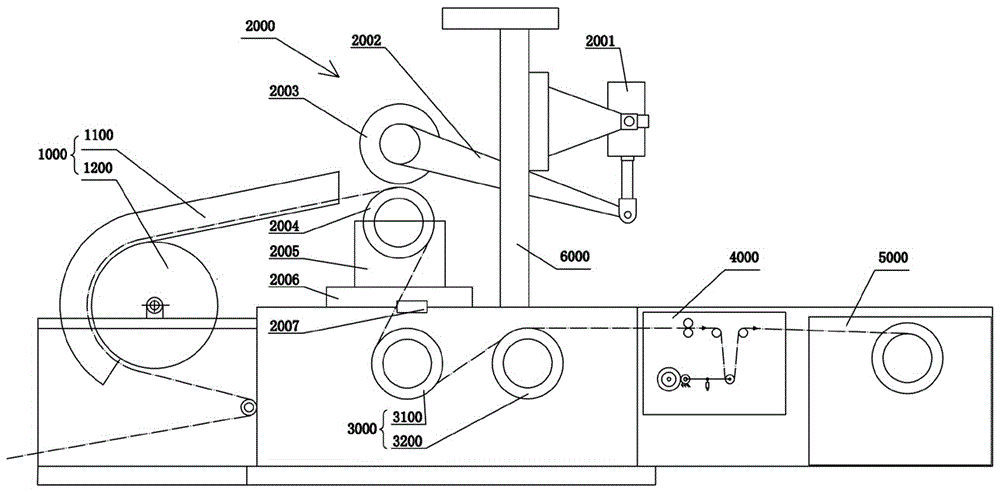

[0034] The wallpaper printing system includes a preheating mechanism 1000, an embossing mechanism 2000, a cooling mechanism 3000, a tension mechanism 4000, a winding mechanism 5000 and a frame 6000.

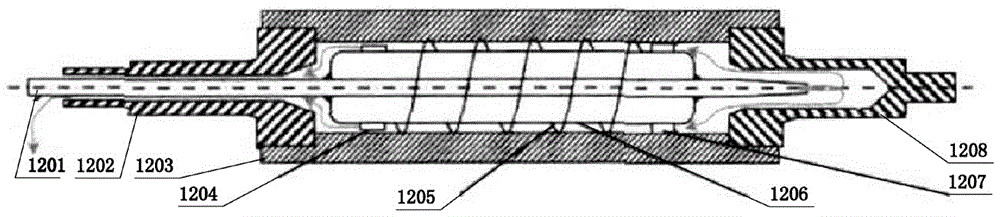

[0035] The preheating mechanism includes a preheating cover 1100 and a heating roller 1200. The preheating cover 1100 is erected on the working surface of the heating roller 1200 to prevent heat loss.

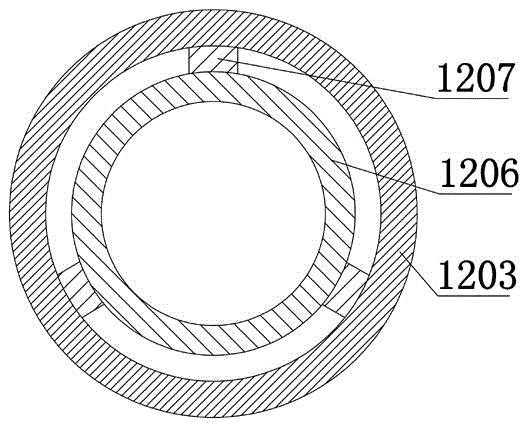

[0036] The heating roller 1200 includes an input shaft 1202, an oil guiding pipe 1201, a heating roller cover 1203, a first sliding block 1204, an oil guiding sleeve 1206, an oil guiding plate 1205, a first fixed block 1207 and a support shaft 1208; the oil guiding sleeve The right end of 1206 is connected to the heating roller cover 1203 through the first fixing block 1207, and the left end is connected to the heating roller cover 1203 through the first sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com