Carrier applicable to construction sites

A construction site and moving vehicle technology, which is applied in the field of construction site handling equipment and moving vehicles, can solve the problems that rickshaws consume a lot of physical strength, low efficiency, and difficulty in entering power vehicles, and achieve the advantages of saving manpower and material resources, simple operation, and large load capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

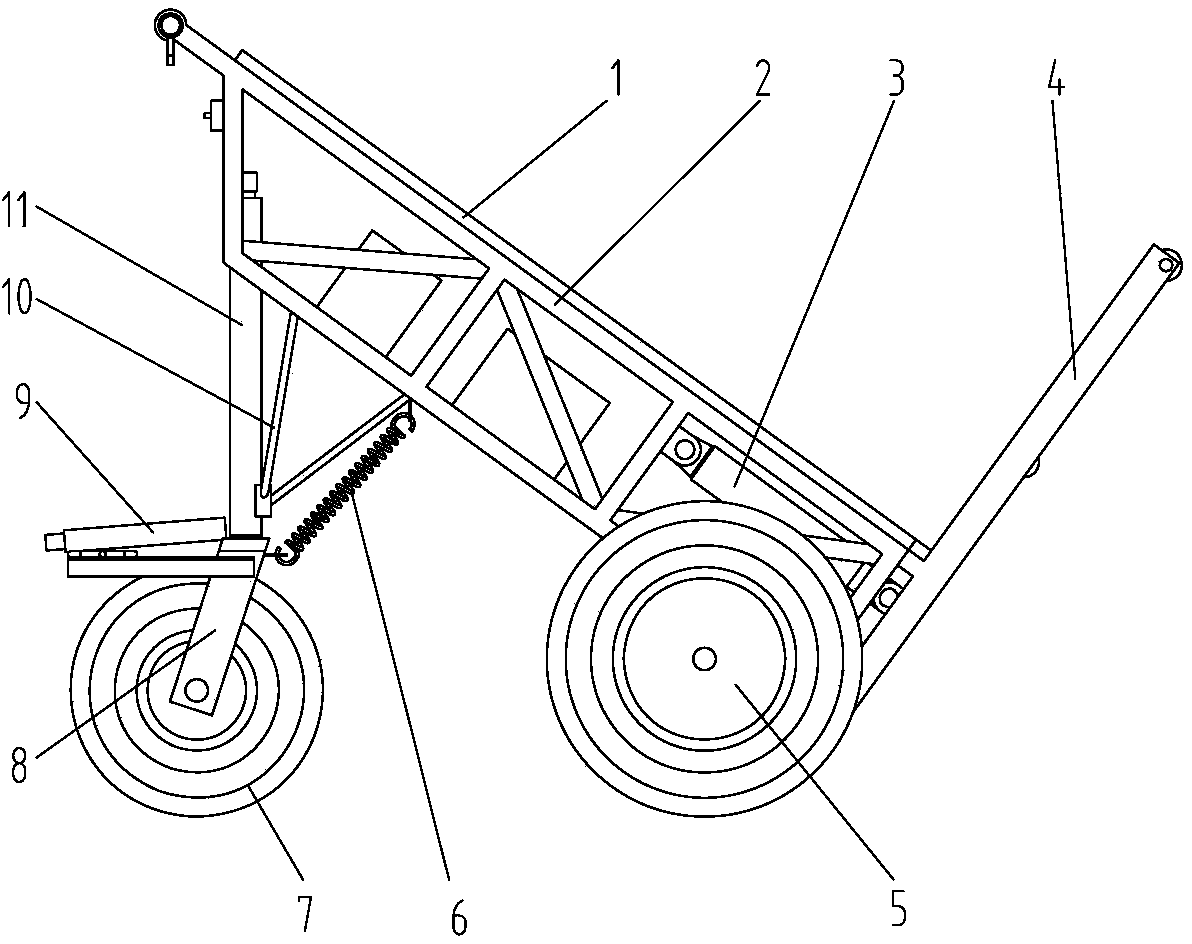

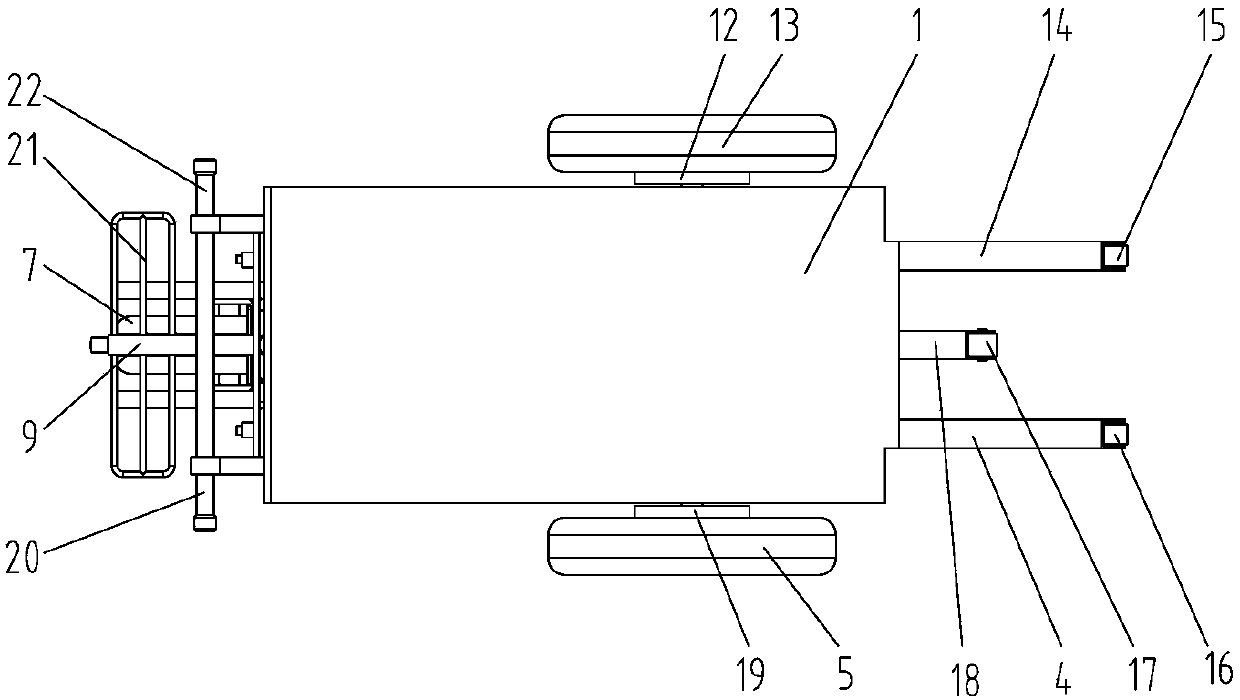

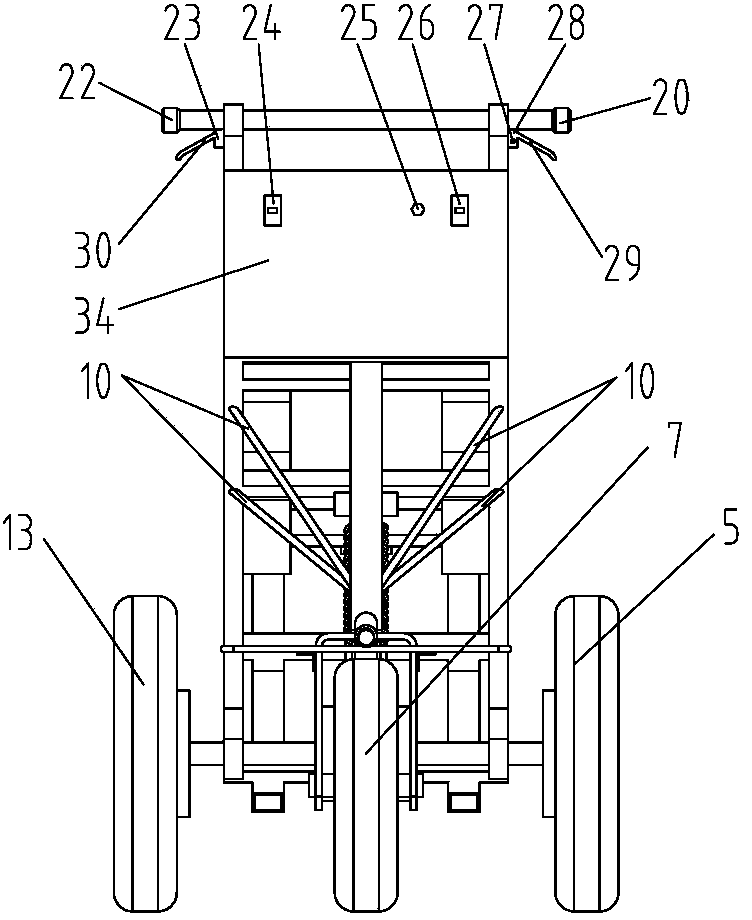

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as Figure 1-7 As shown, the transport vehicle of the present invention includes a vehicle frame 2 and a vehicle plate 1. The vehicle frame 2 adopts a steel frame structure, and the whole is in an inclined shape with a low front and a high rear. The vehicle plate 1 is fixedly laid on the vehicle frame 2, and the front end of the vehicle frame 2 There are two forks 4 and 14 perpendicular to the surface of the vehicle plate 1 by fixed welding, and the ends of the forks 4 and 14 are provided with guide wheels 16 and 15, and the two forks 4 and 14 form an "L" with the vehicle plate 1 Shaped loading platform. In the middle of the lower cross bar at the front end of the vehicle frame 2, there is also a hydraulic cylinder strut 18 that is articulated movably. Looking backward from the front of the vehicle, the hydraulic cylinder strut 18 is positioned in the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com