Take-up reel

A take-up reel, a pair of technology, applied in the field of take-up reels, can solve problems such as unstable product quality, and achieve the effect of easy loading and unloading operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

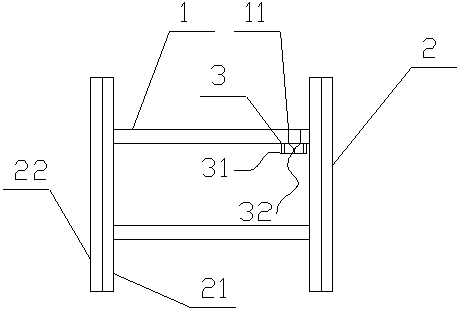

[0010] The take-up reel includes a take-up barrel 1 and a pair of baffles 2, the pair of baffles are arranged symmetrically with the two ends of the take-up barrel, one end of the take-up barrel is provided with a thread end jack 3, and the inner wall of the take-up barrel A fastening mechanism 4 corresponding to the thread end insertion hole is provided.

[0011] The baffle includes a copper disc 21 located inside and an iron disc 22 located outside the copper disc, both of which are fixedly connected.

[0012] The fastening mechanism includes a pair of baffles 31 and a reed insert 32 located in the baffles.

[0013] In the present invention, double-layer baffles are arranged at the end of the wire take-up barrel. The iron disk is convenient for loading and unloading operations, and the soft copper disk can effectively protect the product, ensuring th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com