Automatic safety system for molten iron tanking and operation method thereof

A safety system and molten iron tanker technology, applied in the field of canning equipment, can solve the problems of high operator responsibility, inability to realize automatic filling, and low production efficiency, and achieve high degree of automation, easy operation, and good safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

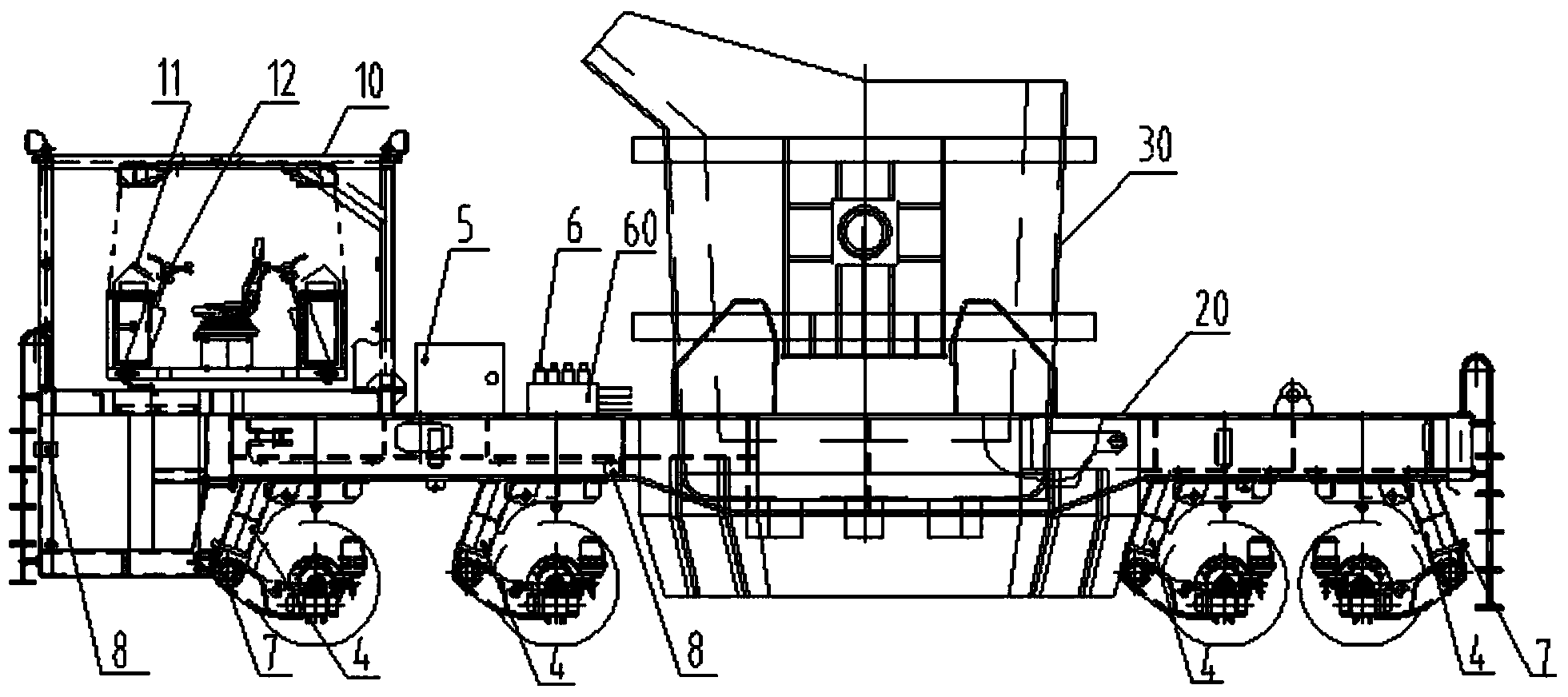

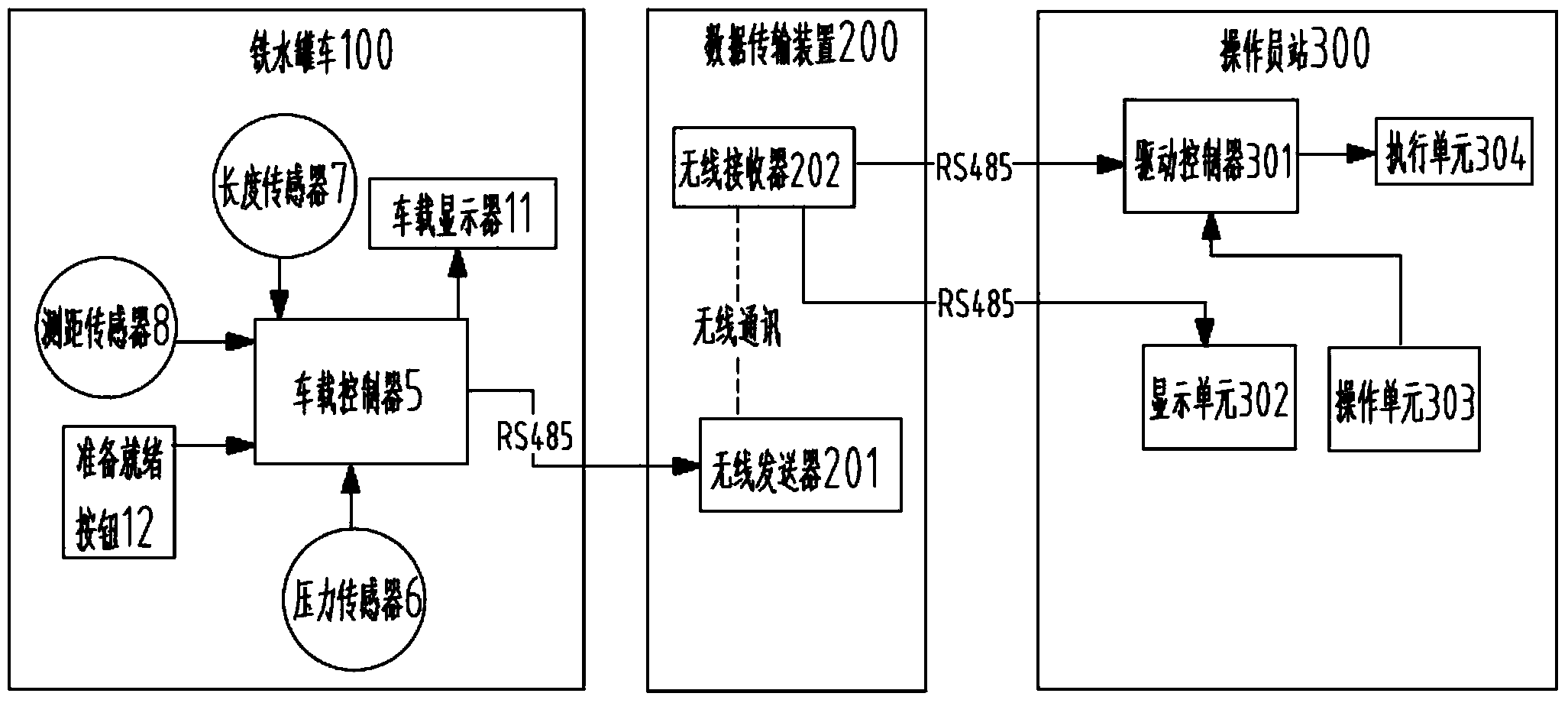

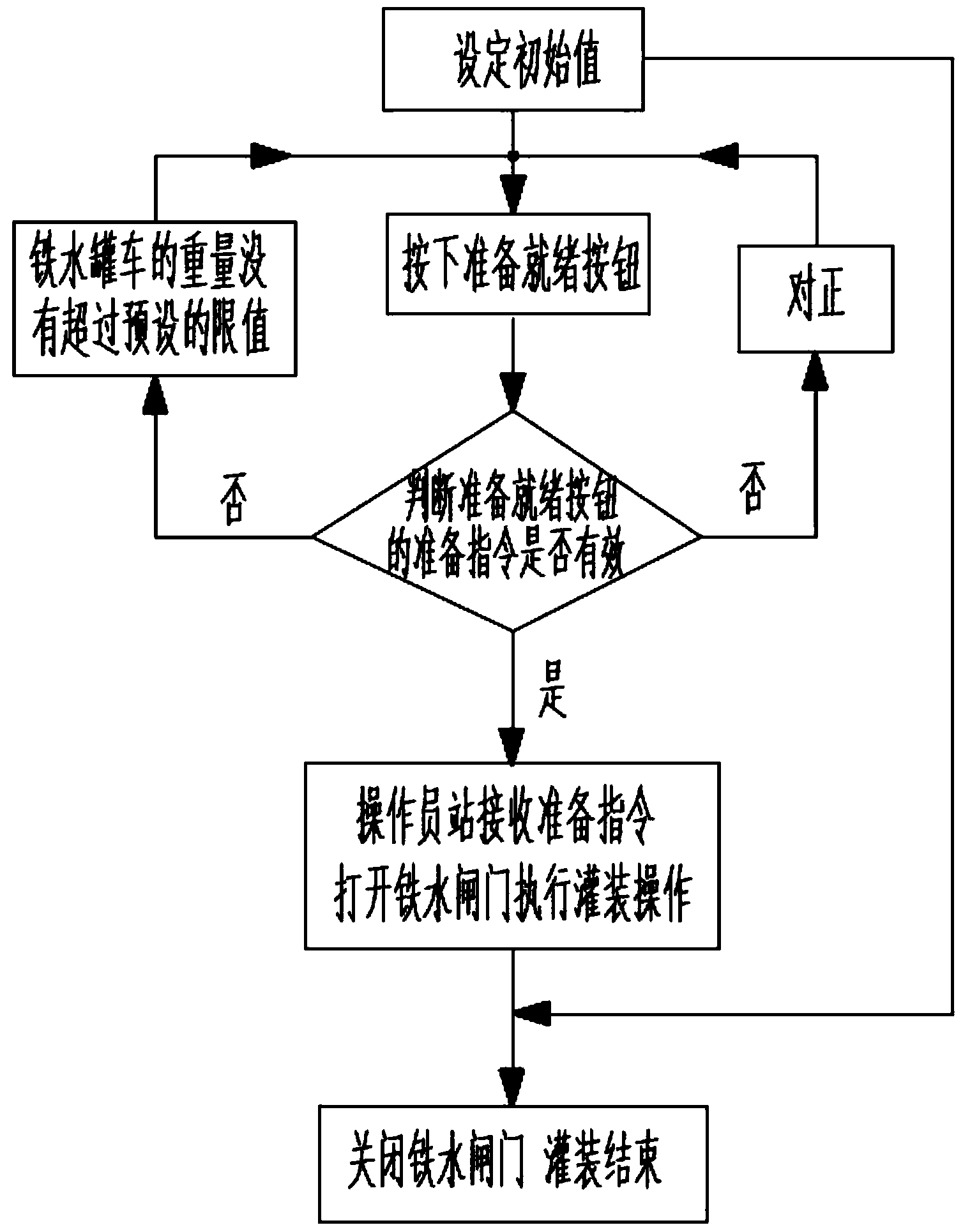

[0024] see figure 1 and figure 2 , the present invention provides an automatic safety system for filling molten iron, comprising a molten iron tank car 100 and an operator station 300 arranged above the molten iron tank car 100 and close to the molten iron gate, and the molten iron tank car 100 and the operator station 300 are connected through data transmission The device 200 is connected by wireless communication, wherein: the molten iron tank car includes a body 20 and at least one cab 10 arranged at the end of the body 20, a molten iron tank 30 for containing molten iron is placed in the middle of the body 20, and several load-bearing Each supporting shaft is provided with a suspension oil cylinder 4 on both sides of each support shaft, a matching pressure sensor 6 is installed on the oil circuit of the sus...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap