A kind of pa6 composite material and preparation method thereof

A technology of composite materials and raw materials, which is applied in the field of PA6 composite materials and its preparation, can solve the problems of thermal decomposition and discoloration of melt viscosity materials, no thermal conductivity, no flame retardancy, etc., and achieve good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

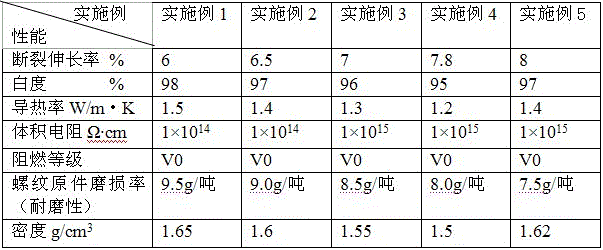

Examples

Embodiment 1

[0099] A PA6 composite material, comprising the following raw materials in mass percentage: 25.4% of PA6 resin, 65% of thermally conductive filler, 5% of halogen-free flame retardant, 2% of toughening agent, 0.4% of coupling agent, 1.0% of surface modifier, Lubricant 1.0%, antioxidant 0.2%.

[0100] Wherein, the relative viscosity of the PA6 resin is 2.0; the Mohs hardness of the thermally conductive filler is 4, the whiteness is 95%, and the average particle size is 1 μm, and the thermally conductive filler is zinc oxide by indirect method; the halogen-free resistor The fuel is bisphenol A bis(diphenyl phosphate); the toughening agent is a mixture of acrylate copolymer and ethylene-acrylate ionomer in a mass ratio of 1:1; the coupling agent is γ ―(2,3-Glycidyloxy)propyltrimethoxysilane; the surface modifier is high molecular weight polysiloxane; the lubricant is saponified montan ester wax, N,N'-hexylene A mixture of bis stearamide and modified ethylene bis fatty acid amide ...

Embodiment 2

[0104] A PA6 composite material, comprising the following raw materials in mass percentage: 30.8% of PA6 resin, 60% of thermally conductive filler, 4% of halogen-free flame retardant, 3% of toughening agent, 0.3% of coupling agent, 0.8% of surface modifier, Lubricant 0.8%, antioxidant 0.3%.

[0105] Wherein, the relative viscosity of the PA6 resin is 2.0; the Mohs hardness of the thermally conductive filler is 3.5, the whiteness is 96%, and the average particle size is between 2 μm, and the thermally conductive filler is synthetic aluminum hydroxide; The halogen flame retardant is resorcinol (diphenyl phosphate); the toughening agent is a mixture of acrylate copolymer and ethylene-acrylate ionomer in a mass ratio of 1:2; the coupling agent It is γ-(2,3-epoxypropoxy)propyltrimethoxysilane; the surface modifier is a mixture of high molecular weight polysiloxane and hyperbranched nylon with a mass ratio of 1:1; the lubricating agent The agent is a mixture of saponified montan es...

Embodiment 3

[0109] A PA6 composite material, comprising the following raw materials in mass percentage: 36.2% of PA6 resin, 55% of thermally conductive filler, 3% of halogen-free flame retardant, 4% of toughening agent, 0.2% of coupling agent, 0.6% of surface modifier, Lubricant 0.6%, antioxidant 0.4%.

[0110] Wherein, the relative viscosity of the PA6 resin is 2.0; the Mohs hardness of the thermally conductive filler is 3, the whiteness is 95%, and the average particle size is between 5 μm, and the thermally conductive filler is synthetic magnesium hydroxide; The halogen flame retardant is triphenyl phosphite; the toughening agent is a mixture of acrylate copolymer and ethylene-acrylate ionomer with a mass ratio of 1:3; the coupling agent is γ-(2 , 3-glycidoxy) propyltrimethoxysilane; the surface modifier is a mixture of high molecular weight polysiloxane and hyperbranched nylon with a mass ratio of 1:2; the lubricant is saponified montan A mixture of ester wax, N, N'-hexylene bis stea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com