High precision planarization method for lithium aluminate crystal material

A flattening method and technology of crystal materials, applied in the field of chemical mechanical polishing, can solve problems such as affecting the surface flatness, and achieve the effects of low roughness, simple operation and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

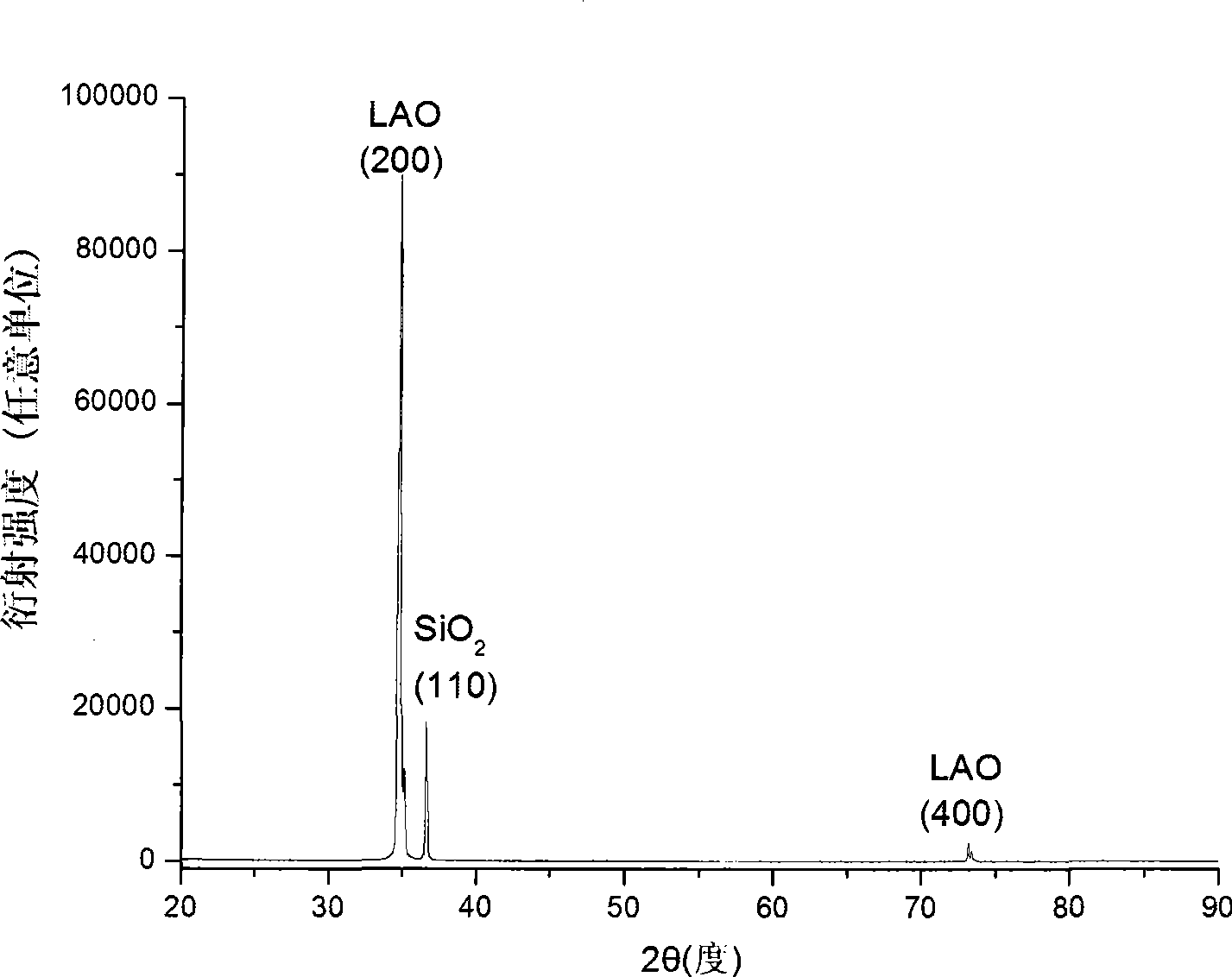

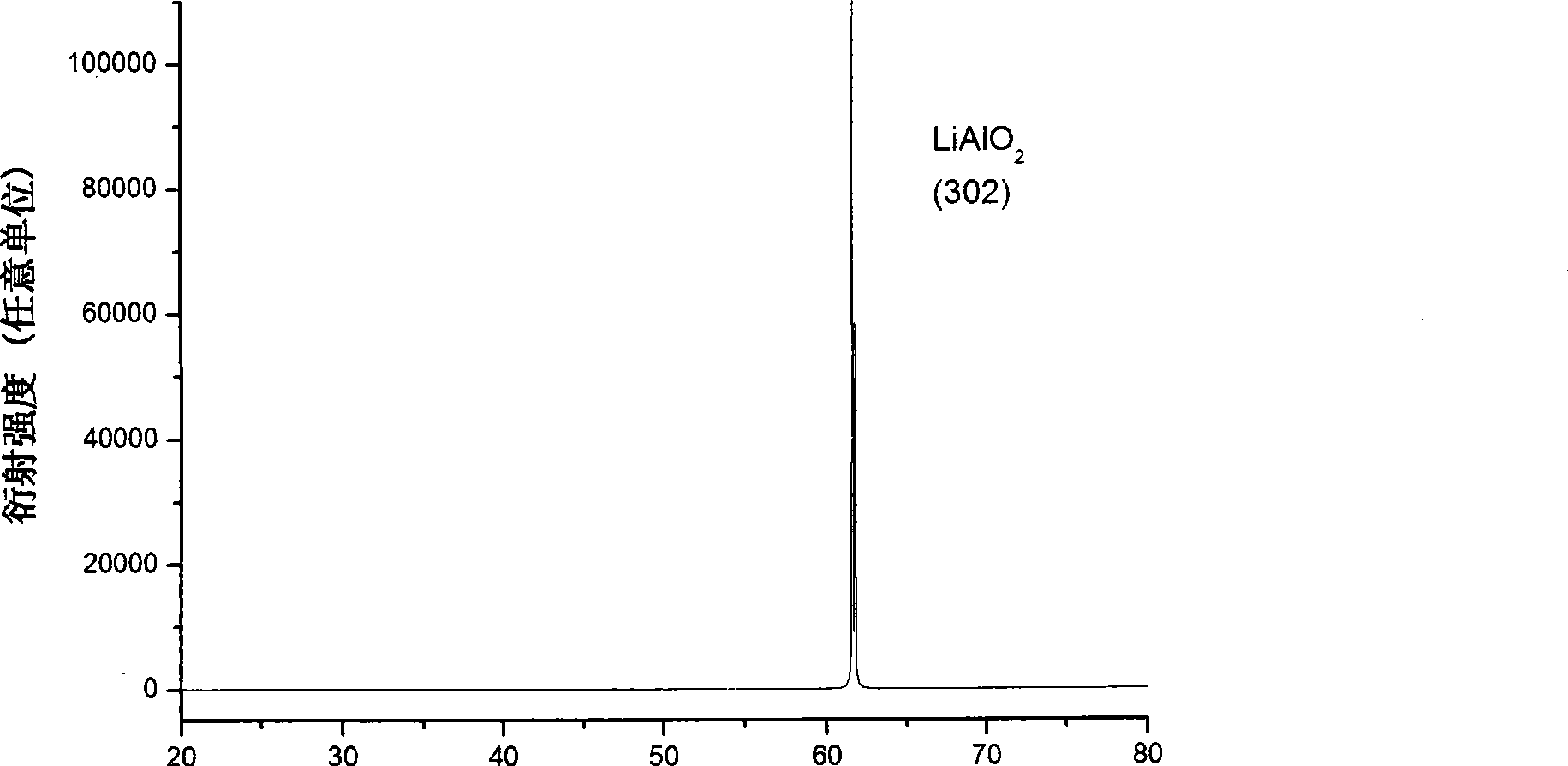

[0033] Take 50% SiO with a particle size of 20nm 2 Sol 800g, put into 2500g deionized water while stirring, then weigh 40g KOH to dilute with 260g deionized water and pour into above-mentioned liquid while stirring, then get 200g amine alkali, 200g O 11 -7((C 10 h 21 -C 6 h 4 -O-CH 2 CH 2 O) 70 -H) Surfactant was poured into the above liquid while stirring, and after stirring evenly, 4000 g of lithium aluminate substrate polishing liquid was obtained. Then for (100)γ-LiAlO 2 The wafer was chemically mechanically polished for 30 minutes at a temperature of 25°C, a rotational speed of 50 rpm, and a pressure of 0.05 MPa. After polishing, rinse the surface of the wafer with a large amount of deionized water, and then ultrasonically clean it in acetone and absolute ethanol for 10 min respectively. By X-ray diffraction detection, a single orientation (110) SiO is formed on the wafer surface 2 film. Low temperature rapid annealing in air atmosphere at 750℃ for 1h, (110)SiO...

Embodiment 2

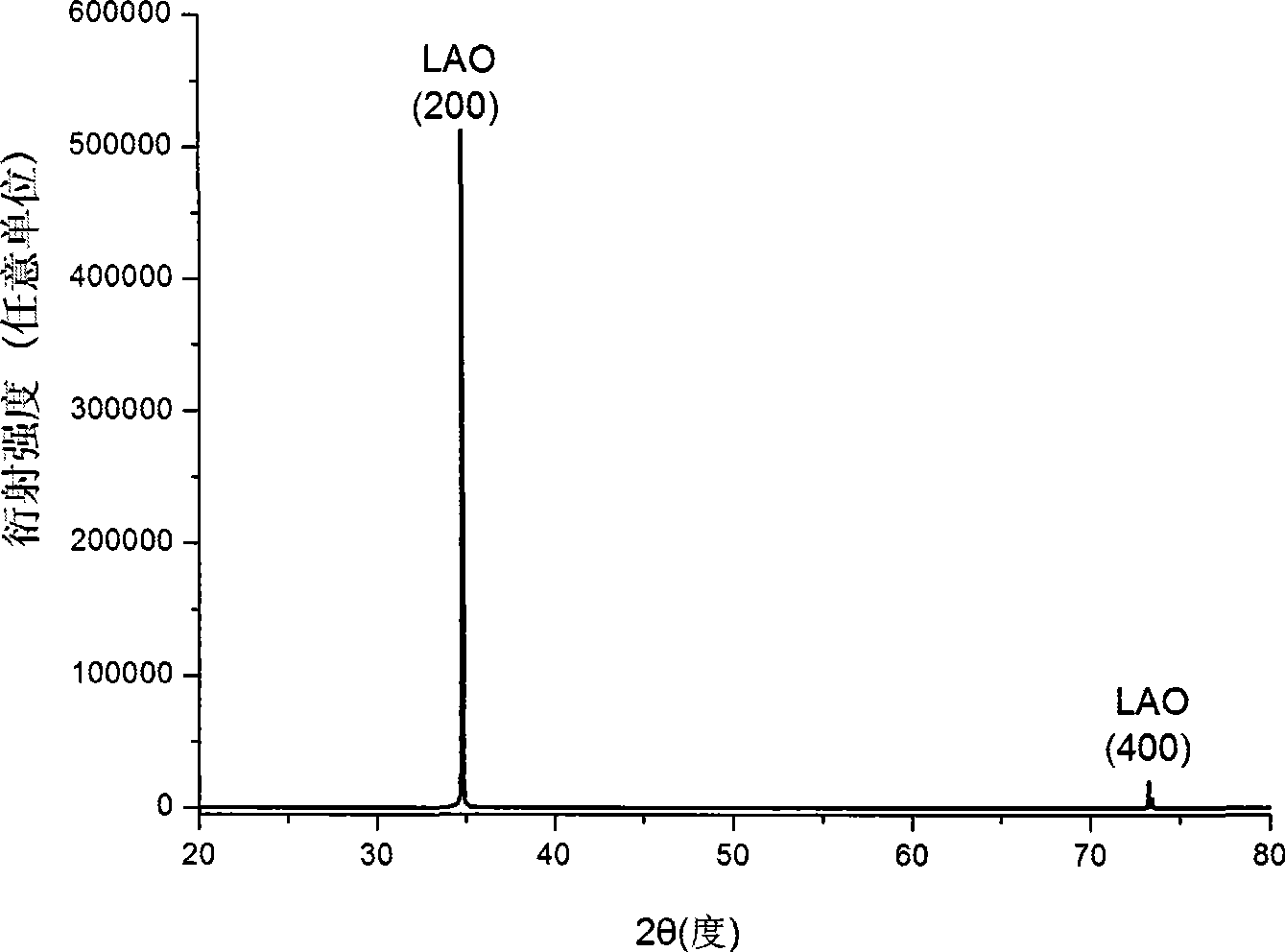

[0035] Take 40% SiO with a particle size of 20nm 2 Sol 2000g, put into 1300g deionized water while stirring, then weigh 40g KOH to dilute with 260g deionized water and pour into the above-mentioned liquid while stirring, then get 200g amine base, 200g O 11 -7((C 10 h 21 -C 6 h 4 -O-CH 2 CH 2 O) 70 -H) Surfactant was poured into the above liquid while stirring, and after stirring evenly, 4000 g of lithium aluminate substrate polishing liquid was obtained. Then for (100)γ-LiAlO 2 The wafer is chemically mechanically polished for 1 hour at a temperature of 30° C., a rotational speed of 70 rpm, and a pressure of 0.05 MPa. After polishing, rinse the surface of the wafer with a large amount of deionized water, and then ultrasonically clean it in acetone and absolute ethanol for 10 min respectively. By X-ray diffraction detection, a single orientation (110) SiO is formed on the wafer surface 2 film. Rapid annealing at low temperature at 800°C for 30 minutes in air atmosphe...

Embodiment 3

[0037] Take 50% SiO with a particle size of 20nm 2 Sol 1200g, put into 2400g deionized water while stirring, weigh 24g KOH then pour into above-mentioned liquid while stirring with 190g deionized water dilution, get 154g amine base again, 32g O 11 -7((C 10 h 21 -C 6 h 4 -O-CH 2 CH 2 O) 70 -H) Surfactant was poured into the above liquid while stirring, and after stirring evenly, 4000 g of lithium aluminate substrate polishing liquid was obtained. Then for (100)γ-LiAlO 2 The wafer was subjected to chemical mechanical polishing for 30 minutes at a temperature of 25° C., a rotational speed of 50 rpm, and a pressure of 0.05 MPa. After polishing, rinse the surface of the wafer with a large amount of deionized water, and then ultrasonically clean it in acetone and absolute ethanol for 10 min respectively. By X-ray diffraction detection, a single orientation (110) SiO is formed on the wafer surface 2 film. Rapid annealing at low temperature at 850°C for 15 minutes in air at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com