Room temperature curable composite coating based on modified 107 silicone rubber and preparation method thereof

A composite coating and silicone rubber technology, applied in the coating and other directions, can solve the problems of pulverization and damage of the paint film, poor weather resistance and aging resistance of the chain segment, and good flexibility of the molecular chain. The effect of good temperature and weather resistance and low film surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

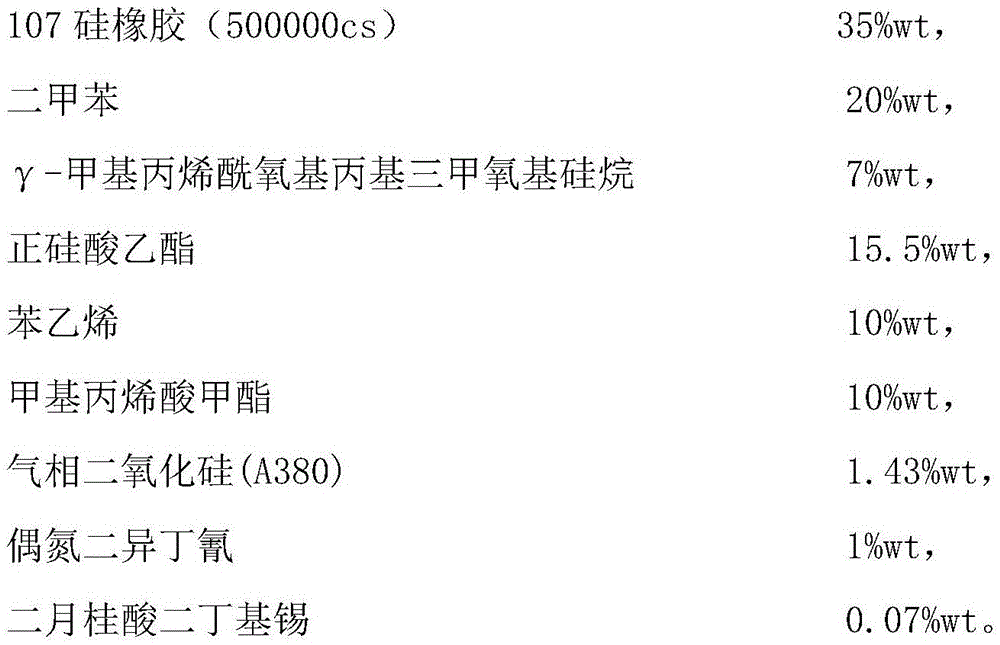

[0020] 1. Raw materials and mass percentage content are:

[0021]

[0022] 2. Preparation method

[0023] (1) Dissolve and disperse 107 silicone rubber in xylene solvent, stir for 5 minutes to dissolve and disperse evenly, then add 20% of the total content of γ-methacryloxypropyltrimethoxysilane and dibutyltin dilaurate dropwise wt, the reaction system was heated while stirring at a temperature of 50° C., and reacted for 2 hours.

[0024] (2) Stir and disperse azobisisobutyronitrile in the mixed monomer of methyl methacrylate / styrene, and gradually add dropwise to the reaction product of step (1) after stirring evenly. During the dropwise addition, the system was kept stirring and the reaction temperature was controlled at 75°C, and the dropwise time was controlled at 10 minutes. After the dropwise addition was completed, the temperature of the reaction system was controlled at 80°C, heated while stirring, and the reaction time was 8 hours. .

[0025] (3) At room tempera...

Embodiment 2

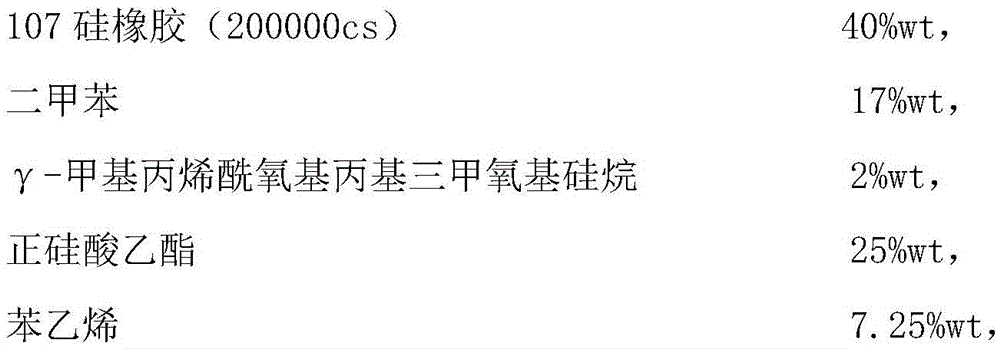

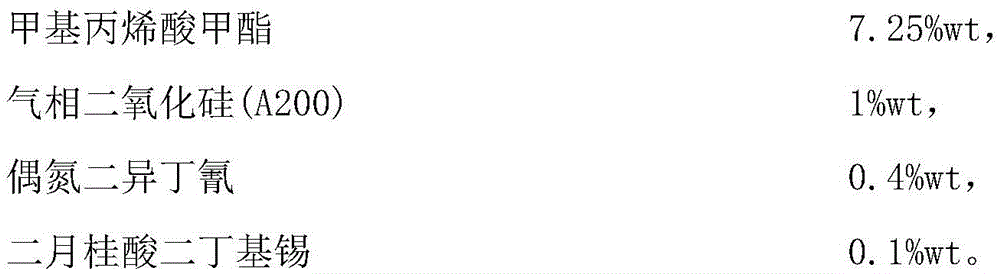

[0027] 1. Raw materials and mass percentage content are:

[0028]

[0029]

[0030] 2. Preparation method

[0031] (1) Dissolve and disperse 107 silicone rubber in xylene solvent, stir for 10 minutes to dissolve and disperse evenly, then add 20% of the total content of γ-methacryloxypropyltrimethoxysilane and dibutyltin dilaurate dropwise wt, the reaction system was heated while stirring at a temperature of 70° C., and reacted for 4 hours.

[0032] (2) Stir and disperse azobisisobutyronitrile in the mixed monomer of methyl methacrylate / styrene, and gradually add dropwise to the reaction product of step (1) after stirring evenly. During the dropwise addition, the system is kept in a stirring state and the reaction temperature is controlled at 60°C, and the dropwise time is controlled at 60 minutes. After the dropwise addition is completed, the temperature of the reaction system is controlled at 100°C, heated while stirring, and the reaction time is 12 hours. .

[0033]...

Embodiment 3

[0035] 1. Raw materials and mass percentage content are:

[0036]

[0037] 2. Preparation method

[0038] (1) Dissolve and disperse 107 silicone rubber in xylene solvent, stir for 7 minutes to dissolve and disperse evenly, then add 20% of the total content of γ-methacryloxypropyltrimethoxysilane and dibutyltin dilaurate dropwise wt, the reaction system was heated while stirring at a temperature of 60° C., and reacted for 3 hours.

[0039] (2) Stir and disperse azobisisobutyronitrile in the mixed monomer of methyl methacrylate / styrene, and gradually add dropwise to the reaction product of step (1) after stirring evenly. During the dropwise addition, the system was kept stirring and the reaction temperature was controlled at 70°C, and the dropwise time was controlled at 30 minutes. After the dropwise addition was completed, the temperature of the reaction system was controlled at 90°C, heated while stirring, and the reaction time was 9 hours. .

[0040] (3) At room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com