L-shaped step-type heat-preserving block brick

A kind of thermal insulation block and step-type technology, which is applied in the field of block bricks to achieve the best thermal insulation effect and the effect of firm walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

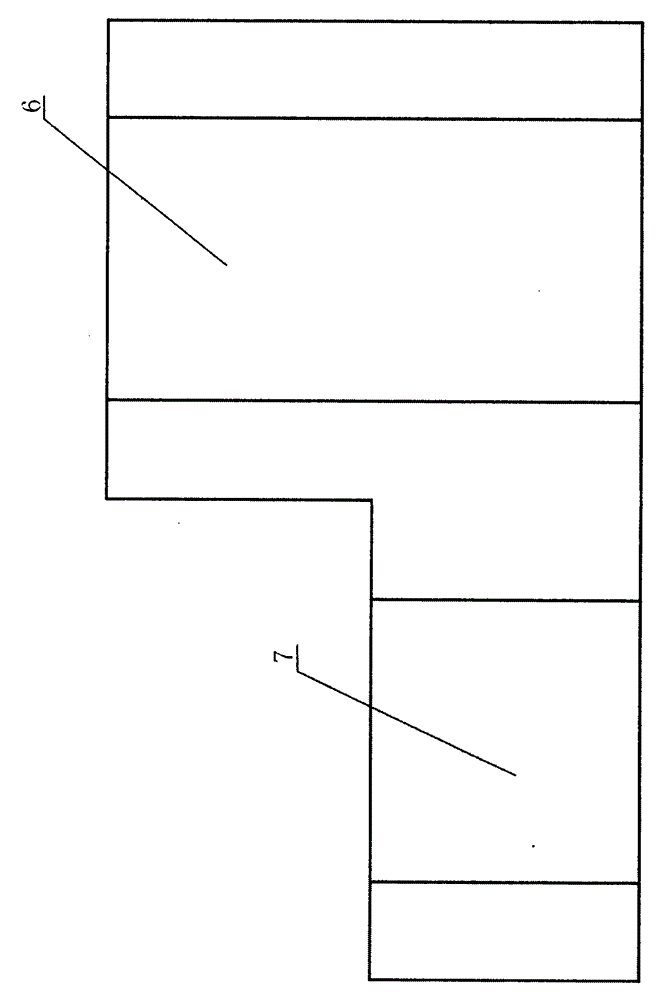

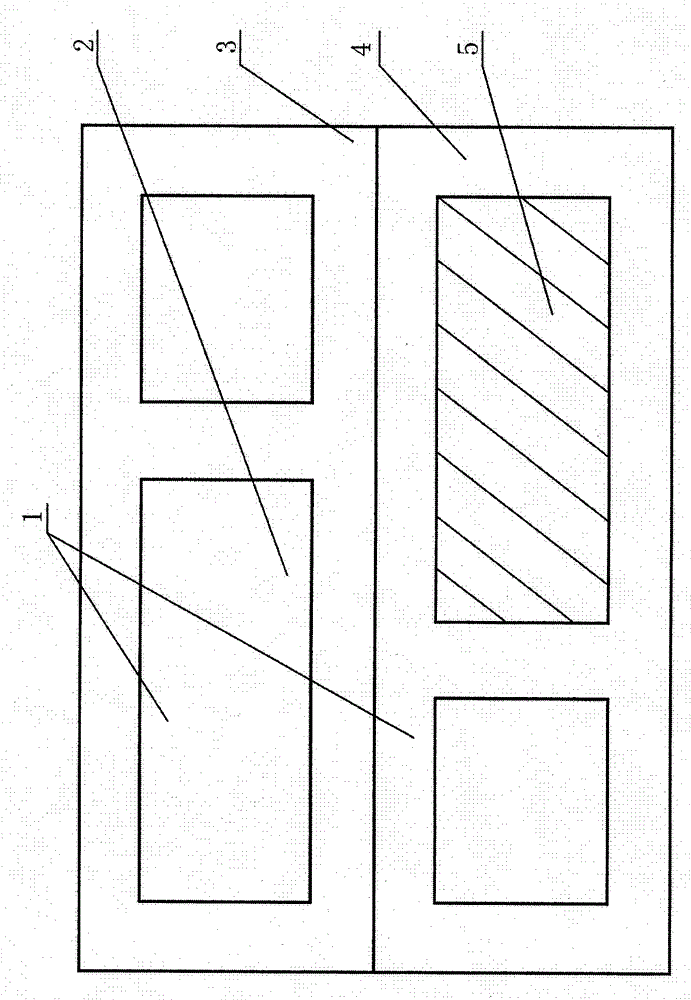

[0010] The special mold installed on the brick machine for L-shaped step-type thermal insulation block bricks forms the brick body 1 and the elongated hole 2 in the brick body 1 at one time, with a height of 3 and a height of 4. In the elongated hole 2, an insulating material 5 is added, and the brick The height of the side width of the body 1 is 6, and the side width of 7 is symmetrical to each other. After curing or firing, each brick body 1 is sequentially superimposed and connected in dislocation to achieve the function of separating the horizontal and vertical joints. , to avoid cold bridge, to achieve the best heat preservation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com