A paperless hot-melt coating device and process

A coating device and hot-melt technology, which is applied to the surface coating liquid device, coating, etc., can solve the problem of high labor cost, and achieve the effect of high cost, simple equipment and process, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

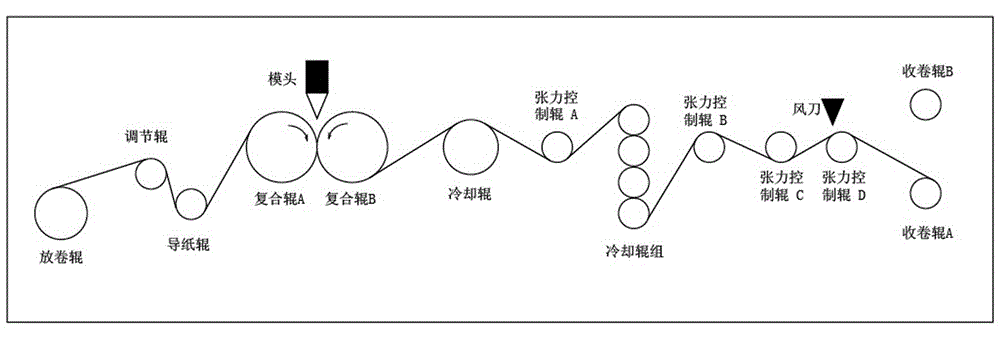

[0023] A process for coating using the above-mentioned paperless hot-melt coating device, comprising the following steps:

[0024] 1. Pour non-agglomerated hot melt rubber particles into the die head, adjust the speed of the die head to 2m / min, and squeeze out the residual glue;

[0025] 2. Adjust the pressure of the unwinding roller to 18MPa, and pass the substrate sequentially through the unwinding roller, regulating roller, paper guide roller, composite roller A, composite roller B, cooling roller, tension control roller A, cooling roller group, and Tension control rolls B, C, D, and finally drawn to take-up roll A or B;

[0026] 3. Set the base material tension of the unwinding roller to 25Mpa, and it is advisable that the knitted fabric does not stretch or wrinkle;

[0027] 4. After observing that the film on the die head of the extruder is transparent and smooth, cut off the film on the die head of the extruder, remove the rubber baffle on the extruder, and move the die...

Embodiment 2

[0030] A process for coating using the above-mentioned paperless hot-melt coating device, comprising the following steps:

[0031] 1. Pour the non-agglomerated hot melt rubber particles into the die head, adjust the speed of the die head to 4m / min, and squeeze out the residual glue;

[0032] 2. Adjust the pressure of the unwinding roller to 19MPa, and pass the substrate sequentially through the unwinding roller, regulating roller, paper guide roller, composite roller A, composite roller B, cooling roller, tension control roller A, cooling roller group, and Tension control rolls B, C, D, and finally drawn to take-up roll A or B;

[0033] 3. Set the base material tension of the unwinding roller to 25Mpa, and it is advisable that the knitted fabric does not stretch or wrinkle;

[0034] 4. After observing that the film on the die head of the extruder is transparent and smooth, cut off the film on the die head of the extruder, remove the rubber baffle on the extruder, and move the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com