A spoke type shield cutter head

A shield cutter head and cutter head technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems that the shield machine cannot be pushed normally, affects the progress of the project, and the wear of the shield cutter head, so as to improve the construction of ground breaking capacity, avoiding construction progress, and reducing construction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

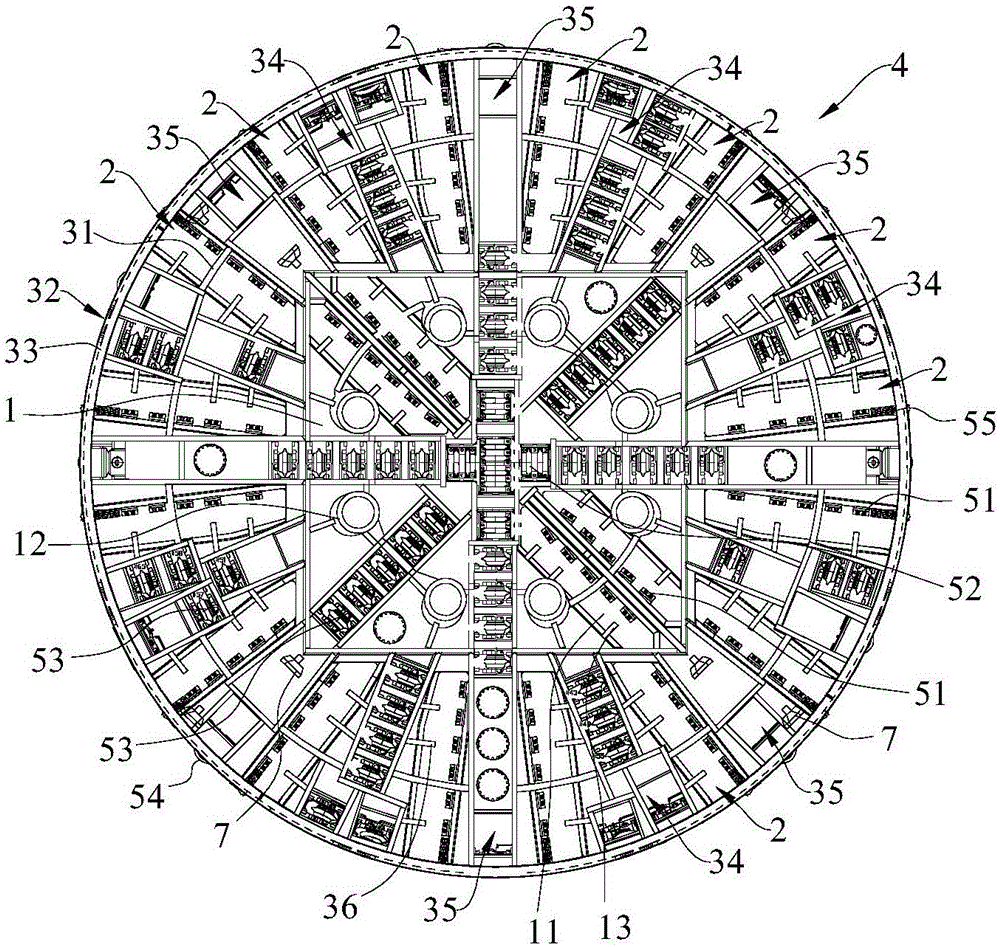

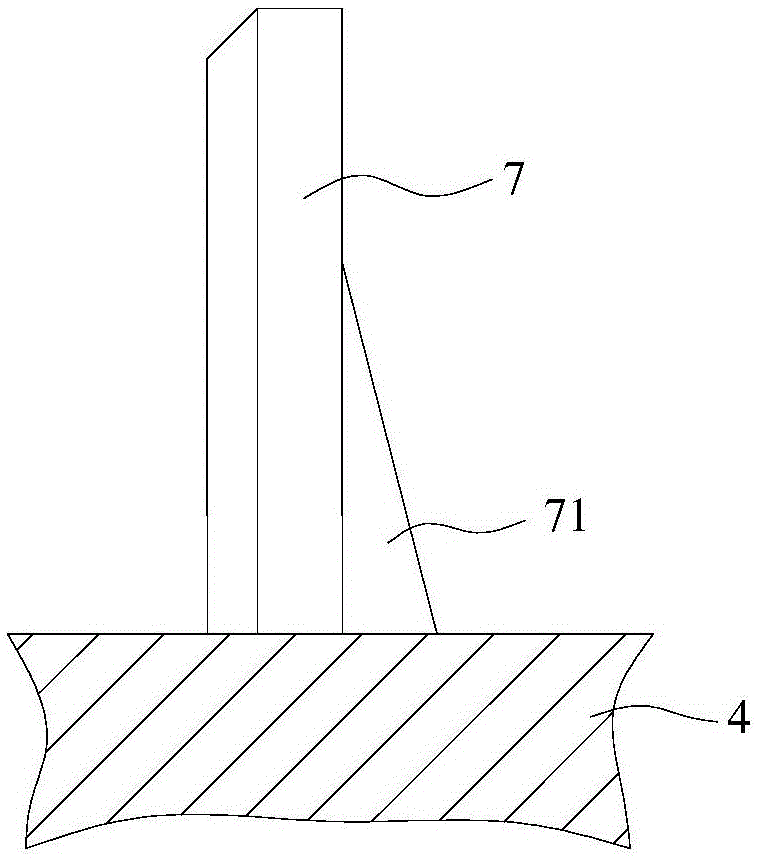

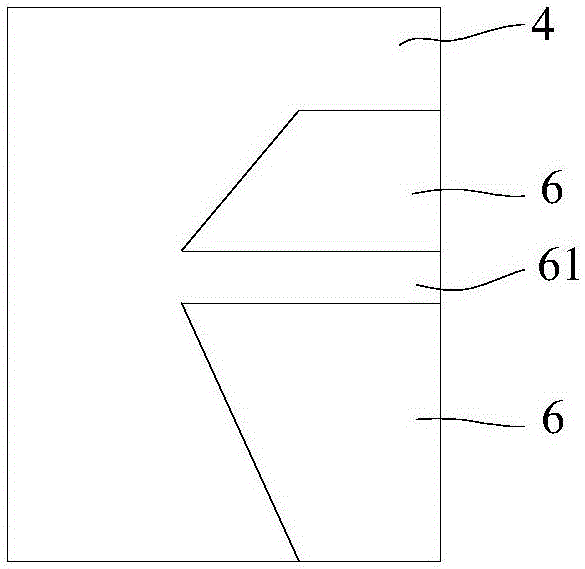

[0022] refer to Figure 1 to Figure 3 , the present invention provides a spoke-type shield cutterhead, comprising a cutterhead body 1 and 16 cutterhead webs arranged on the periphery of the cutterhead body 1 and spaced apart from each other to form 16 first through slots 2, The cutterhead main body 1 and each cutterhead web are fixedly connected to form a disc-shaped cutterhead 4 , and a connecting rib 31 connecting each cutterhead web is provided through the first through groove 2 . The outer circular surface of the cutterhead 4 is provided with an annular plate 32 connecting each cutterhead web 3 , and a wear-resistant plate 33 is welded on the back of the cutterhead 4 on the annular plate 32 . The main body of the cutterhead 1 is square as a whole, and is provided with four cutter mounting ribs which intersect each other at the center of the cutter head main body 1 and form an angle of 45° with each other. The first installation rib and a second installation rib with sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com