Negative flow hydraulic control circuit, method, actuator and system

A control circuit and hydraulic system technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the problems of power consumption, large and medium power loss, and the inability to adjust the hydraulic system pressure, etc., to achieve Reduce the median power loss, reduce the median power loss, the effect of small pressure and displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

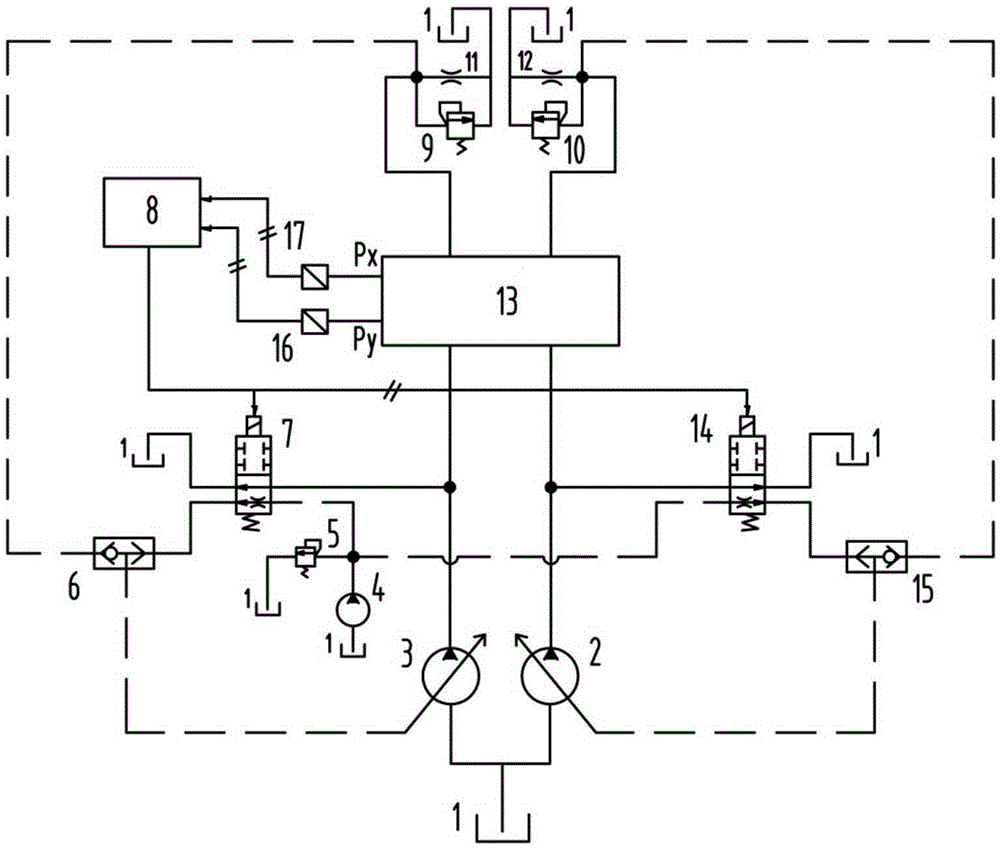

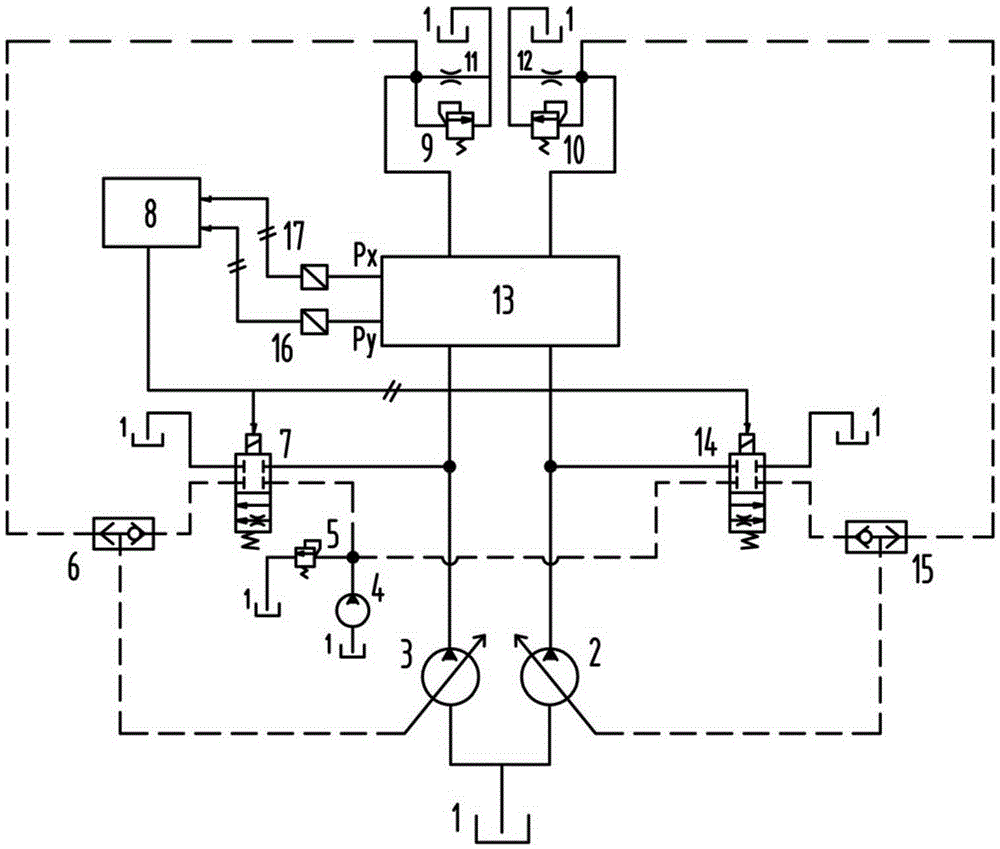

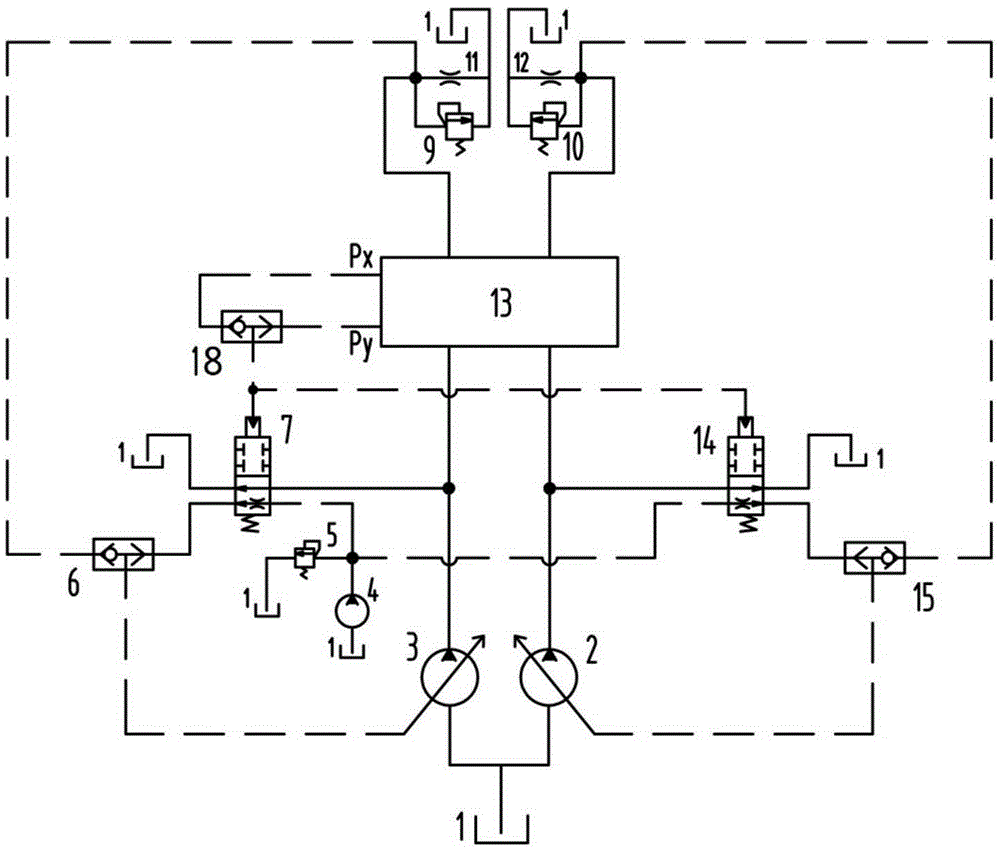

[0027] According to an embodiment of the present invention, the negative flow hydraulic control circuit may include an unloading valve, the first oil inlet of the unloading valve is connected to the corresponding oil outlet of the variable displacement pump, the first oil outlet is connected to the The hydraulic oil tank is connected to control the on-off of the unloading circuit.

[0028] Moreover, the negative flow hydraulic control circuit may also include a shuttle valve, wherein the first oil inlet of the shuttle valve is connected to the oil inlet of the corresponding negative flow orifice, and the oil outlet of the shuttle valve is connected to the oil inlet of the corresponding negative flow orifice. The corresponding variable pump regulator is connected to form the first negative flow control loop; and the second oil inlet of the shuttle valve is connected with the second oil outlet of the unloading valve, and the outlet of the shuttle valve The oil port is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com