Clip-off digital automatic intelligent sampling machine

A fully automatic, sampling machine technology, applied in the direction of analyzing materials, instruments, etc., can solve problems such as the inability to ensure that the needle does not stay below, the device cannot be connected, and the equipment is damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

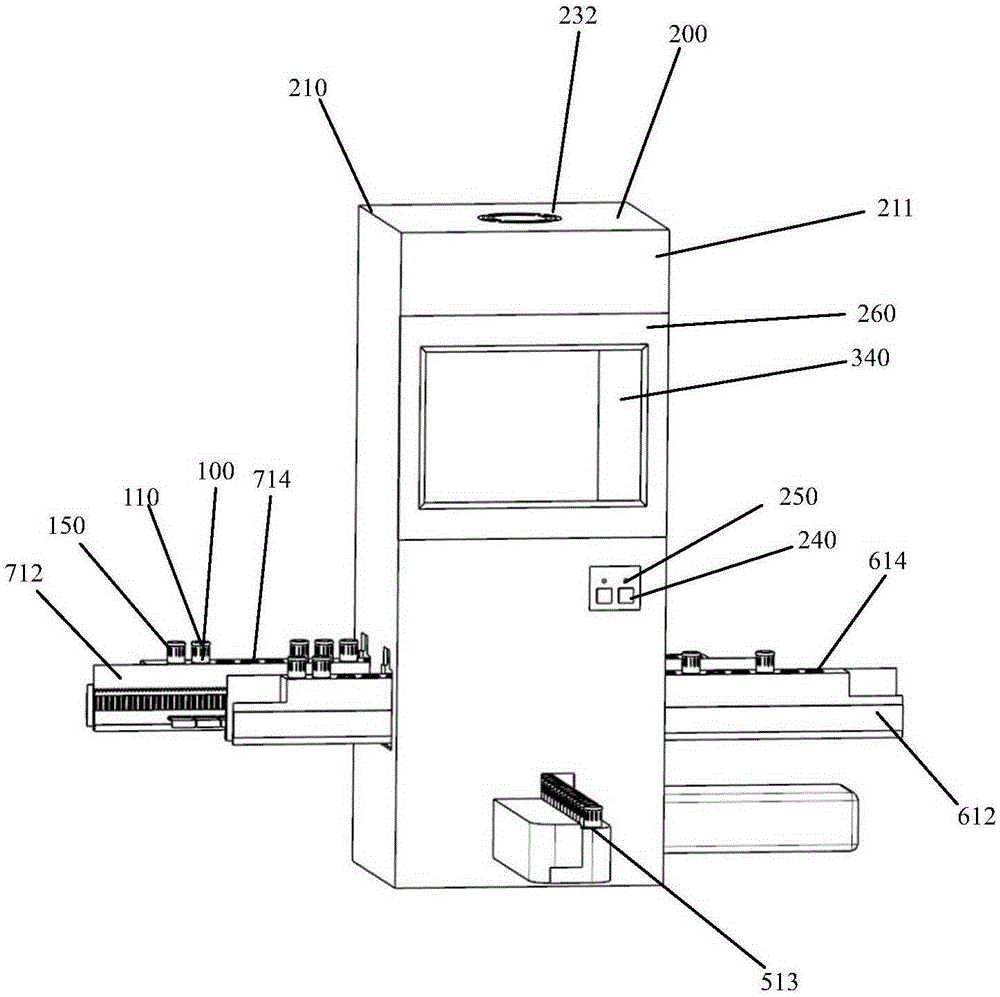

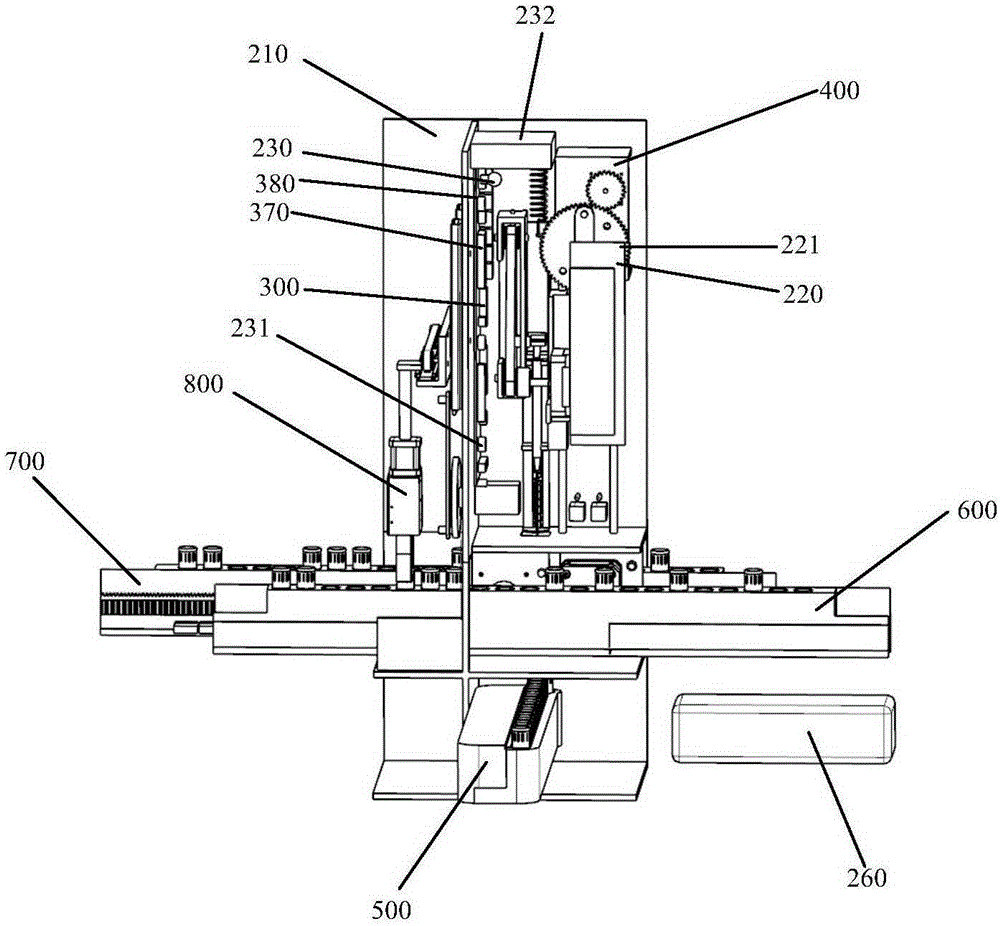

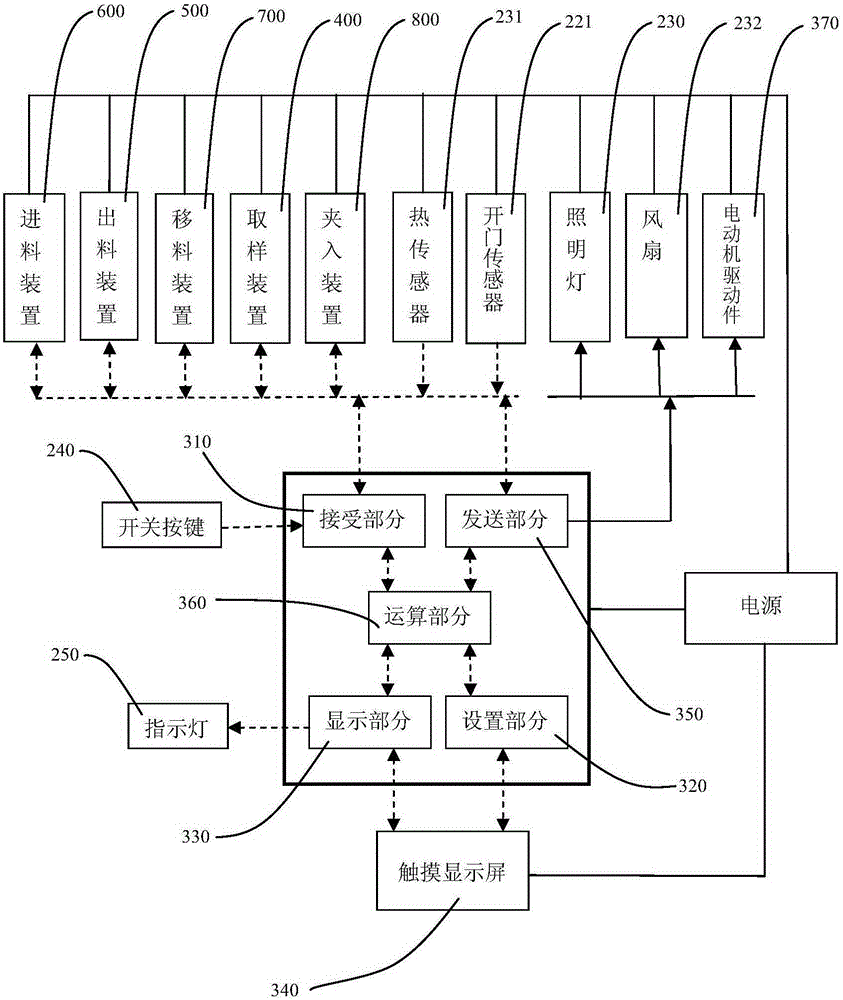

[0115] With reference to the accompanying drawings, figure 1 is an outline view of the present invention, figure 2 It is a sectional view of the overall structure of the present invention, image 3 is a schematic diagram of the circuit frame of the control device 300, and the rest are views of components, which will be described separately below with reference to the accompanying drawings.

[0116] figure 1 Display: the shell 211 is connected to the shell frame 210, the switch button 240 and the indicator light 250 are arranged on the surface of the shell 211, and 260 is a power supply.

[0117] The door 220 is on the upper part of the front of the casing 211, and the door 220 can be opened and closed.

[0118] The touch display screen 340 is installed on the outside of the door 220 .

[0119] The fan 232 is at the top of the housing ( 200 ) 200 .

[0120] The container lid 110 is on the top of the container 100, and the labels 150 are respectively attached to the contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com