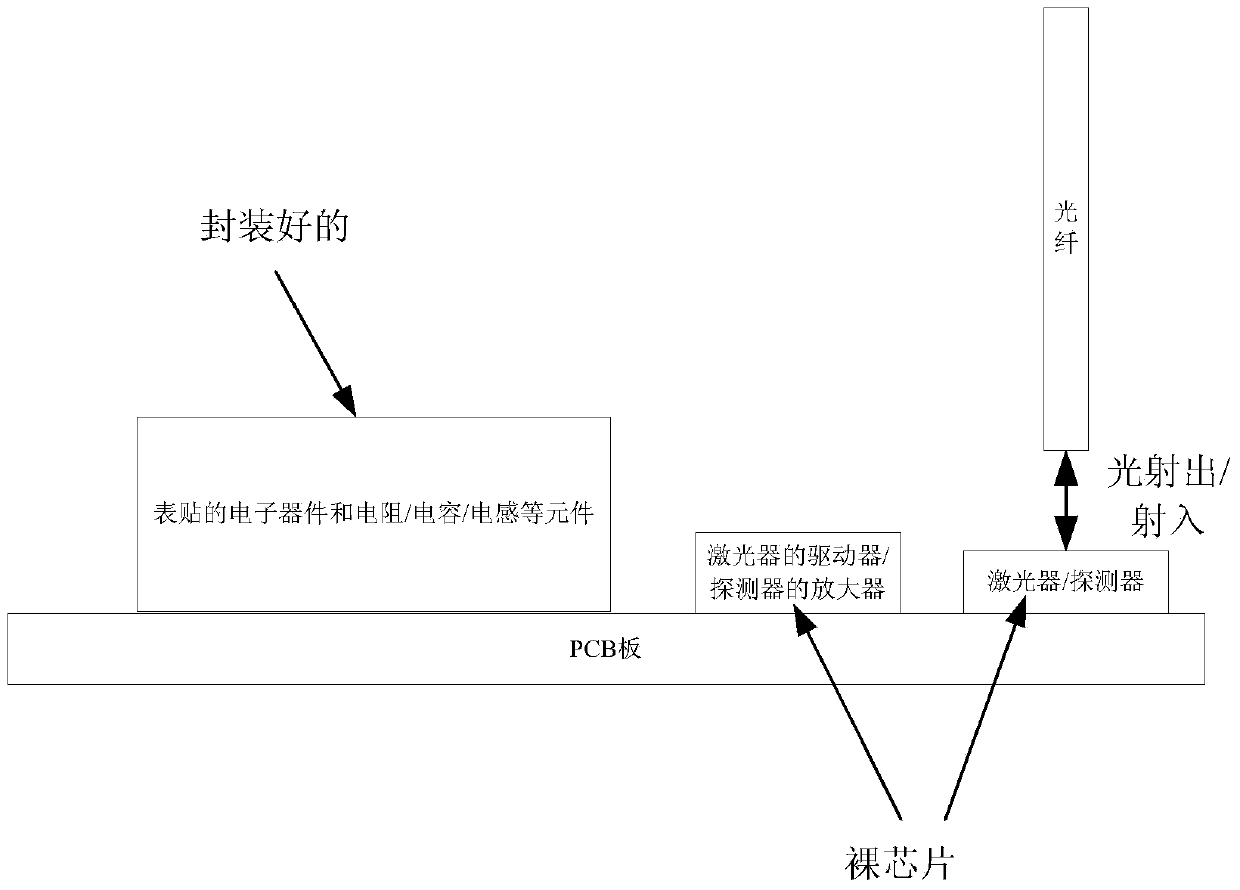

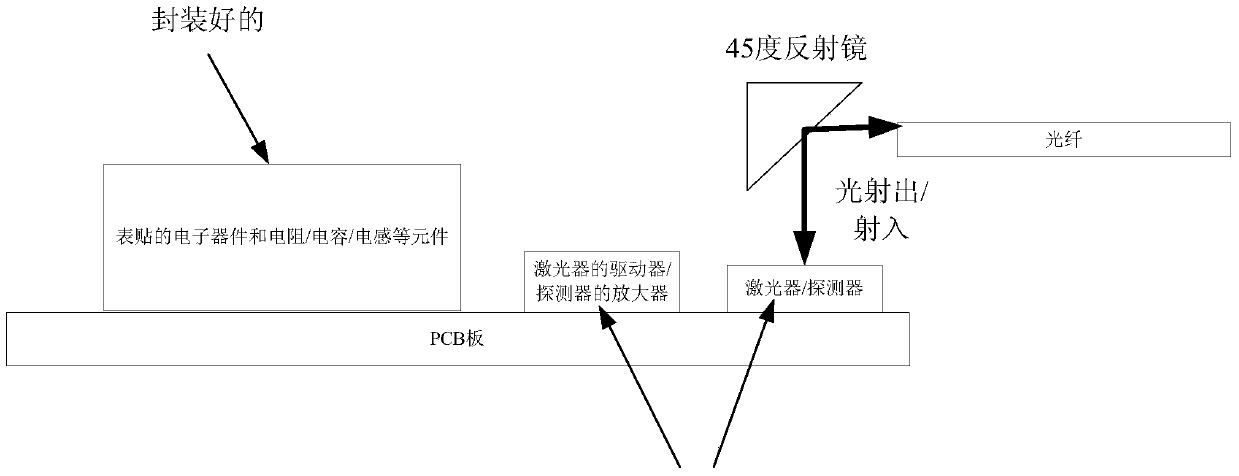

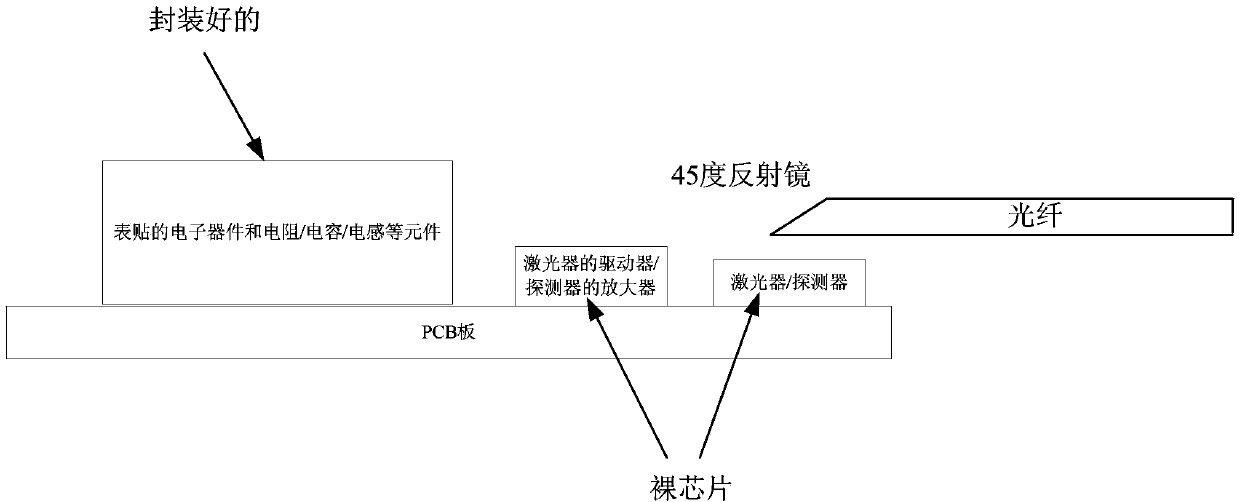

Structure and manufacturing method of optical transceiver module

An optical transceiver module and spacer technology, which is applied in the coupling of optical waveguides, electrical components, and electrical solid-state devices, etc., can solve the problems of unbalanced technology maturity, technical difficulties in optoelectronic parts, and high access thresholds, and achieve convenient splicing. Simple, low cost, thinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0044] The structure of the optical transceiver module proposed by the present invention, such as Figure 5As shown, a spacer 11 is included, and a pure electric part 101 and a photoelectric part 201 that are independent and electrically connected are adjacently carried on the spacer 11 .

[0045] The optoelectronic part 201 includes a carrier 1, the side of the carrier 1 is mounted on the spacer 11, one side of the carrier 1 is fixed to the spacer 11, the other side and the top surface are provided with metal wiring 2, and the top surface of the carrier 1 The metal wiring 2 is provided with bumps 3, and the photoelectric conversion chip 4 is mounted upside down on the top surface of the carrier 1 through the bumps 3, and is electrically connected with the metal wiring 2; Holes 12, one or more optical fibers 7 are inserted laterally in each through hole 12 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com