High strength steel plate having excellent brittle crack arrestability and method for manufacturing same

A thick steel plate, high-strength technology, applied in the direction of metal rolling, etc., can solve the problems of difficult control of production scale and large load, and achieve the effect of excellent brittle crack propagation stop characteristics and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

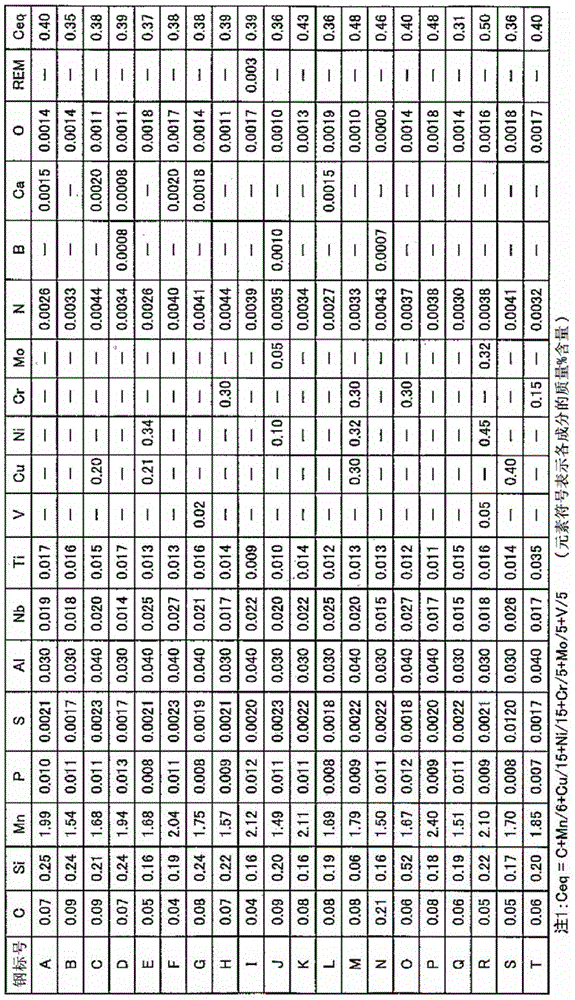

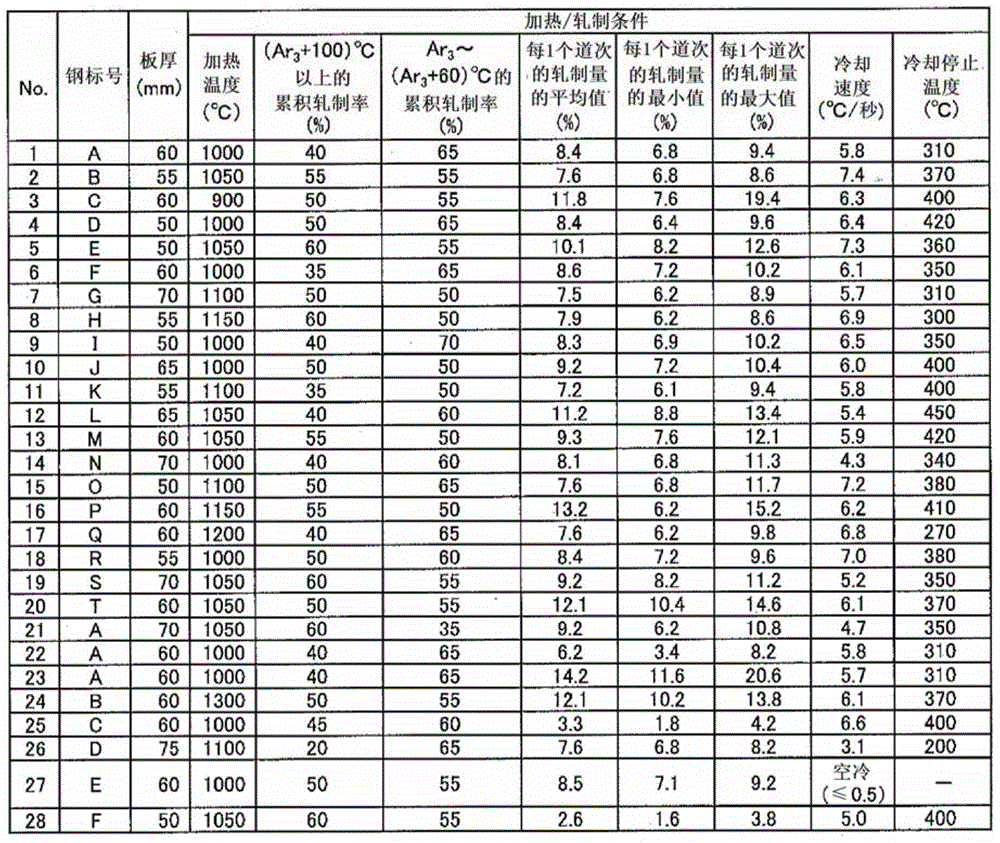

[0095] Molten steel (steel codes A to T) of each composition shown in Table 1 was smelted in a converter, and made into steel raw materials (slab thickness 280 mm) by continuous casting, hot rolled to a plate thickness of 50 to 75 mm, and then cooled. The test steels No. 1-28 were obtained. Table 2 shows hot rolling conditions and cooling conditions. Ar 3 The point (° C.) was calculated by the following formula.

[0096] Ar 3 Point = 910-273C-74Mn-57Ni-16Cr-9Mo-5Cu

[0097] Wherein, the symbol of each element is the mass % content in the steel, and it is 0 when not contained.

[0098] Table 1

[0099]

[0100] Table 2

[0101]

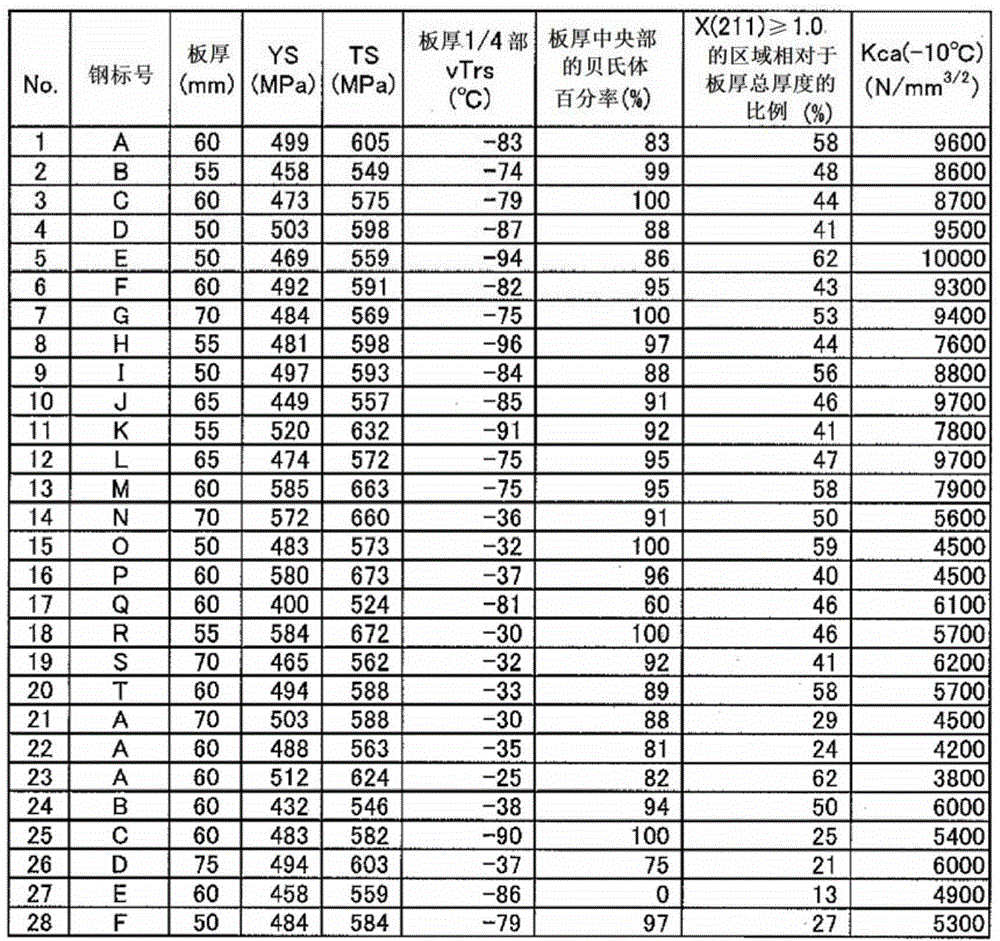

[0102] For the obtained thick steel plate, a JIS14A test piece of Φ14 with the longitudinal direction perpendicular to the rolling direction was cut out from the 1 / 4 part of the plate thickness, and subjected to a tensile test to measure the yield strength (YS), tensile strength, and tensile strength. Strength (TS).

[0103] Cut out a JIS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com