Film-Type Negative Electrode Filled With Active Material And Method For Manufacturing Same

A cathode electrode and active material technology, which is applied in the field of cathode electrode filled with active material in the form of a film and its preparation, can solve the problems of weak life characteristics and safety, achieve the effect of reducing electrolyte consumption and improving life characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

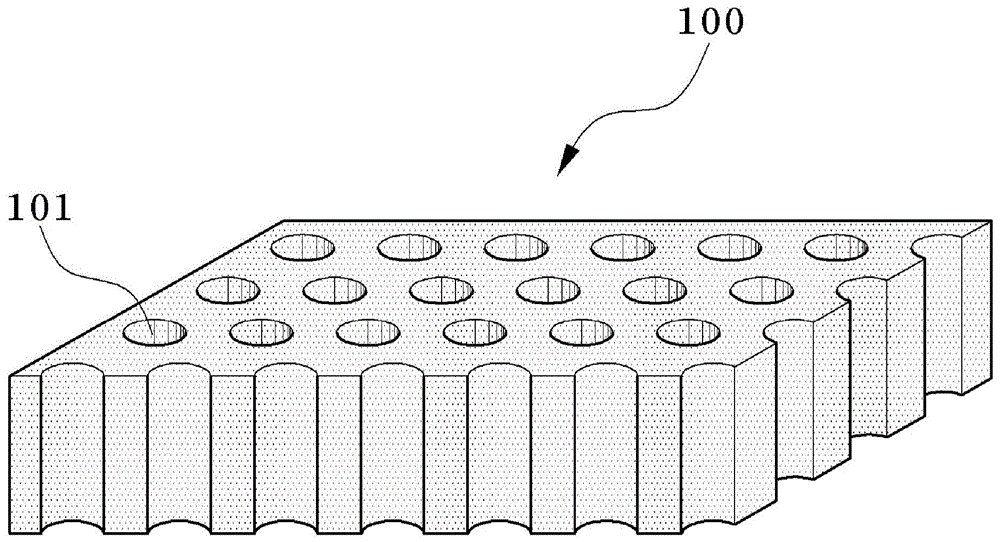

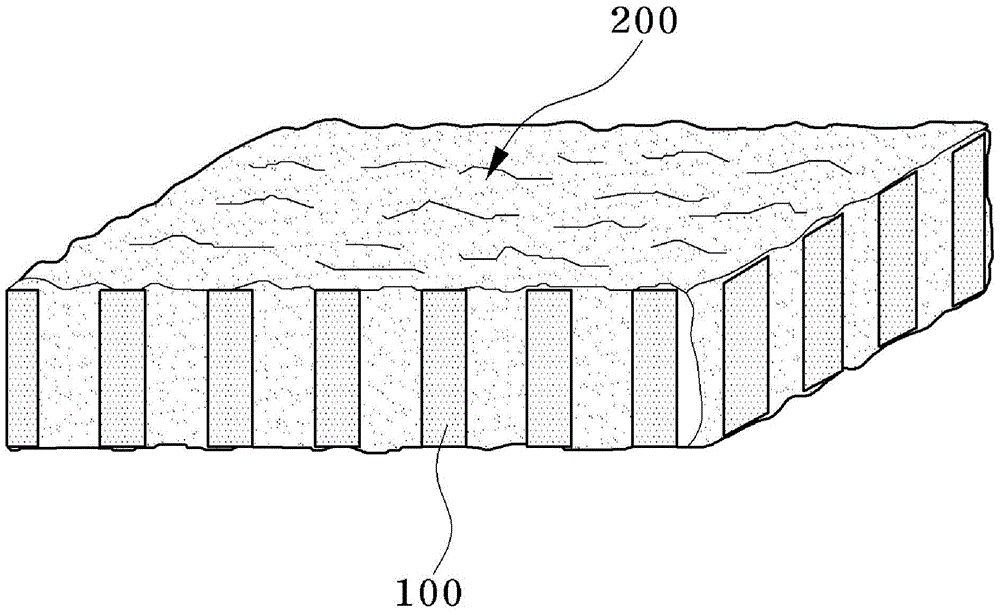

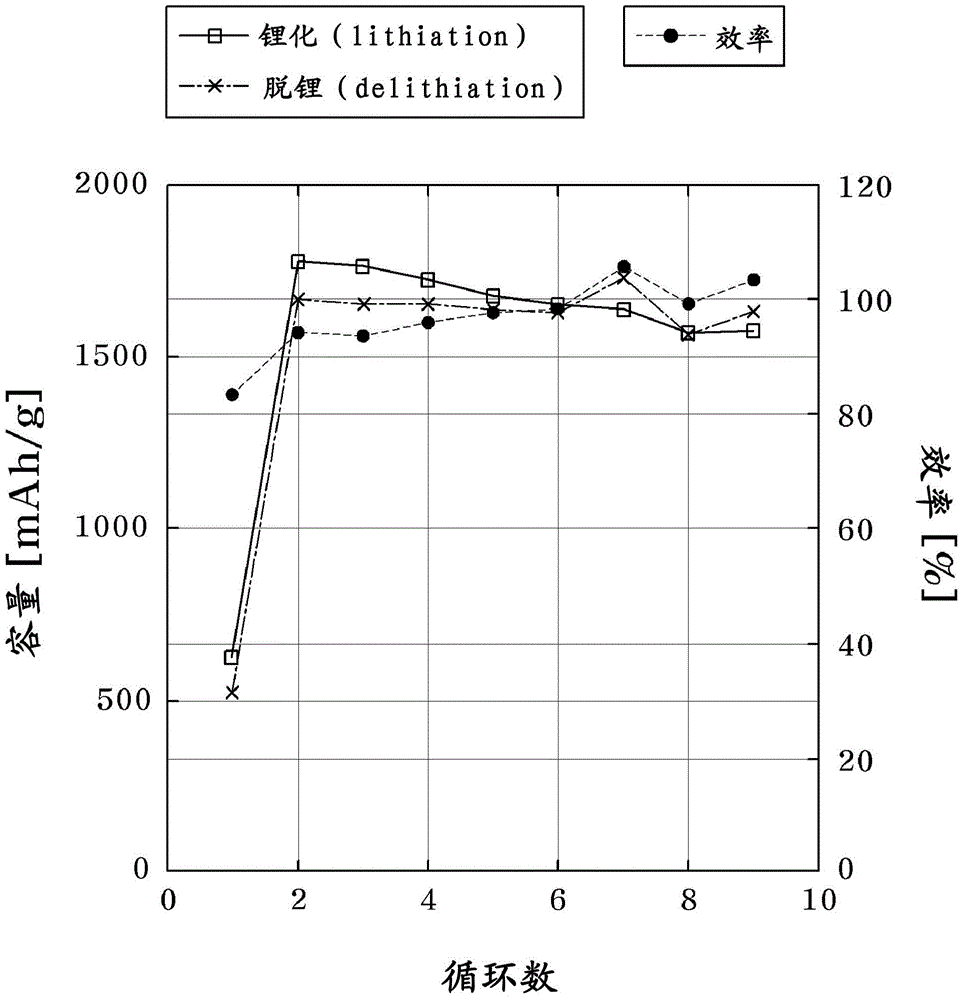

[0060] Si nanoparticles (Sigma-Aldrich Si nanopowder (633097, <100nm)) sold in the market were mixed with a binder (PVDF) and a conductive additive (Sigma-Aldrich GMC (graphite Mesoporous carbon, 699627, <35nm)) was dispersed in 10 ml of organic solvent (NMP) to prepare active material slurry. Then, after coating a porous film (GLPE, 100nm, 300MPa) on the current collector with a thickness of 25 μm, the organic solvent was evaporated on a hot plate heated at 110° C. for 5 hours, thereby manufacturing a film filled with the above-mentioned active material. A cathode electrode in the form of a porous film of slurry. (Active material filling rate: 36%)

Embodiment 2

[0062] Si nanoparticles prepared by mechanical pulverization with an average particle size of 50nm and a binder (PVDF) and a conductive additive (Sigma-Aldrich GMC (graphitized mesoporous carbon, 699627, <35nm)) were prepared at a ratio of 6.5:2.5:1 After mixing in the weight ratio, it was dispersed in 10 ml of an organic solvent (NMP) to prepare an active material slurry. Then, after coating a porous film (GLPE, 100nm, 300MPa) on the current collector with a thickness of ~25μm, the organic solvent was evaporated on a hot plate heated at 110°C for 5 hours, thereby manufacturing the above-mentioned active film. A cathode electrode in the form of a porous film of material slurry. (Active material filling rate: 29.25%)

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com