Phase change cold-storage composite material and preparation method thereof

A composite material, phase change cold storage technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor cold storage and heat transfer performance of eutectic salt, hindering popularization and application, and high equipment investment, and achieve good thermal stability. , Improve the thermal conductivity, improve the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

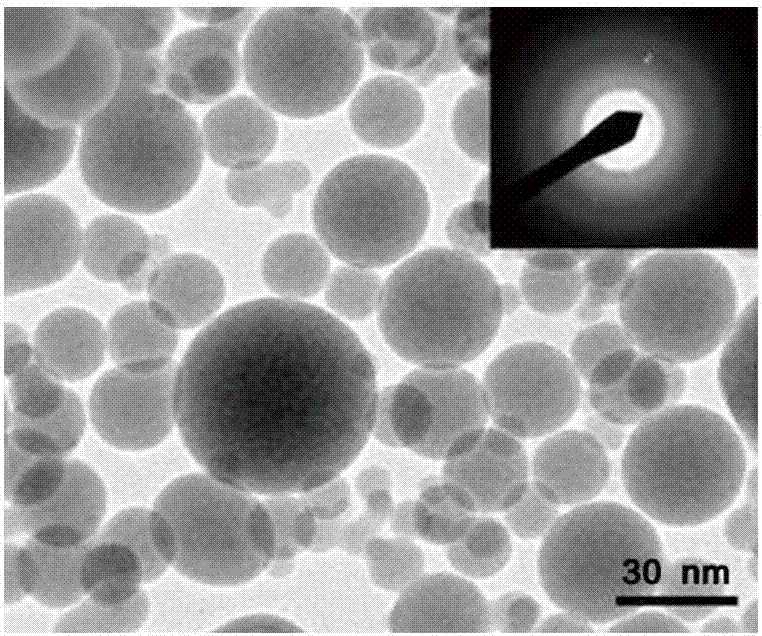

Embodiment 1

[0026] A phase-change cold storage composite material, comprising the following raw materials, a sol with a mass ratio of 45.8:78 and a hydrangea acid / phytol solution, the sol including nano-titanium dioxide, aluminum ammonium sulfate, Polyvinylpyrrolidone, deionized water. The particle size of the nano-titanium dioxide is 25nm, and the crystal form is rutile. The rutile type has a thermodynamically stable phase, and the anatase phase has a relatively strong oxidizing property, and the prepared phase change cold storage material has better performance.

[0027] The above-mentioned phase change cold storage composite material is prepared by the following method, including the following steps, according to the above mass ratio, 1 g of nano-titanium dioxide, 180 g of aluminum ammonium sulfate, and 20 g of polyvinylpyrrolidone are dispersed in 257 g of deionized water, stirred and mixed for 10 minutes, and ultrasonically Treat for 1 hour at a frequency of 40 kHz to make a sol, mi...

Embodiment 2

[0030] A phase change cold storage composite material, comprising the following raw materials, a sol with a mass ratio of 54.2:93.4 and a hydrangea acid / phytol solution, the sol including nano-titanium dioxide, aluminum ammonium sulfate, Polyvinylpyrrolidone, deionized water. The particle size of the nano-titanium dioxide is 25nm, and the crystal form is rutile.

[0031] The above-mentioned phase-change cold storage composite material is prepared by the following method, including the following steps, according to the above-mentioned mass ratio, 8 g of nano-titanium dioxide, 210 g of aluminum ammonium sulfate, and 25 g of polyvinyl pyrrolidone are dispersed in 299 g of deionized water, stirred and mixed for 15 minutes, and ultrasonically Treat for 1.5 hours with a frequency of 40 kHz to make a sol, mix the sol with the hydrangea acid / phytol solution, and disperse for 40 minutes to obtain a phase change cold storage composite material.

[0032] Wherein, the mass ratio of hydra...

Embodiment 3

[0034] A phase change cold storage composite material, comprising the following raw materials, a sol with a mass ratio of 52:80 and a hydrangea acid / phytol solution, and the sol includes nano-titanium dioxide, aluminum ammonium sulfate, Polyvinylpyrrolidone, deionized water. The particle size of the nano-titanium dioxide is 25nm, and the crystal form is rutile.

[0035] The above-mentioned phase-change cold storage composite material is prepared by the following method, including the following steps, according to the above-mentioned mass ratio, 2 g of nano-titanium dioxide, 190 g of aluminum ammonium sulfate, and 21 g of polyvinylpyrrolidone are dispersed in 260 g of deionized water, stirred and mixed for 12 minutes, and ultrasonically Treat for 1.2 hours with a frequency of 40 kHz to make a sol, mix the sol with the hydrangea acid / phytol solution, and disperse for 30 minutes to obtain a phase change cold storage composite material.

[0036] Wherein, the mass ratio of hydrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com