Gypsum powder and application thereof

A technology of gypsum powder and gypsum, which is applied to building components, buildings, door leaves, etc. It can solve the problems of poor fire resistance, corroded door panels, degumming and hollowing of door panels, etc., and achieves short initial setting time and final setting time, good strength and fire protection performance, high dry compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

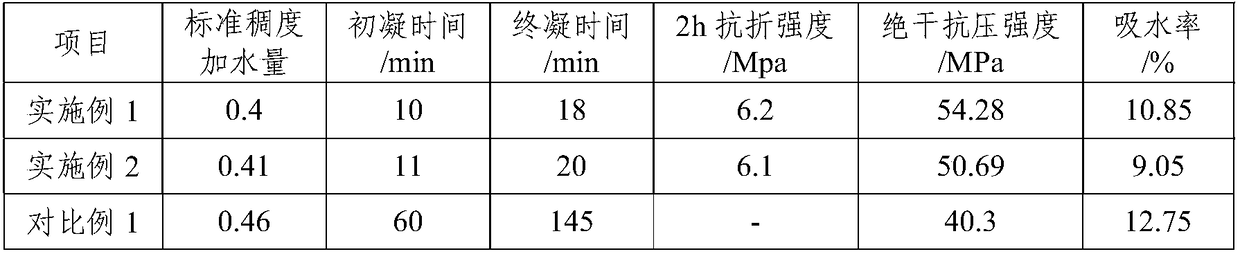

Examples

Embodiment 1

[0025] A kind of gypsum powder for the production of fire door core board, which is composed of the following components by weight: 100 parts of α gypsum, 3 parts of P.O 52.5 white cement as a strengthening agent, 1 part of sulphoaluminate cement as a volume stabilizer, and setting time adjustment 0.01 part of citric acid as agent, 0.1 part of silicone amide as foam stabilizer, 3 parts of emulsified paraffin wax as waterproofing agent, and 0.1 part of short glass fiber as toughening agent.

Embodiment 2

[0027] A kind of gypsum powder for the production of fire door core board, which is composed of the following components by weight: 100 parts of α gypsum, 3 parts of P.O 52.5 white cement as a strengthening agent, 1 part of sulphoaluminate cement as a volume stabilizer, and setting time adjustment 0.01 part of citric acid, 0.1 part of sodium dodecylbenzenesulfonate foam stabilizer, 0.2 part of silane water repellent, 0.1 part of short glass fiber toughening agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com