Bolted steel-structure pool body applicable to compressor

A concentrator and steel structure technology, applied in the direction of settlement tanks, etc., can solve the problems of long installation period, many scattered parts, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

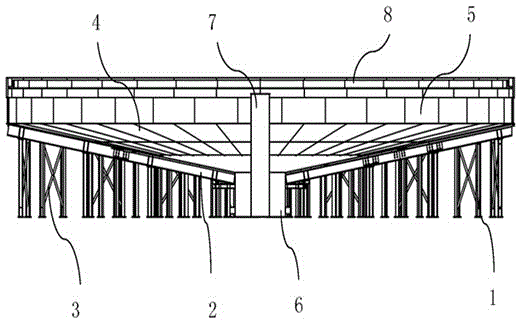

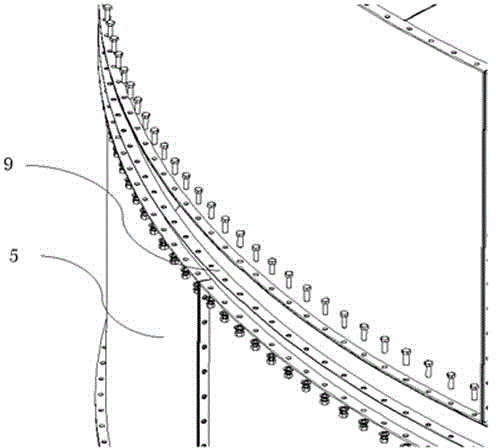

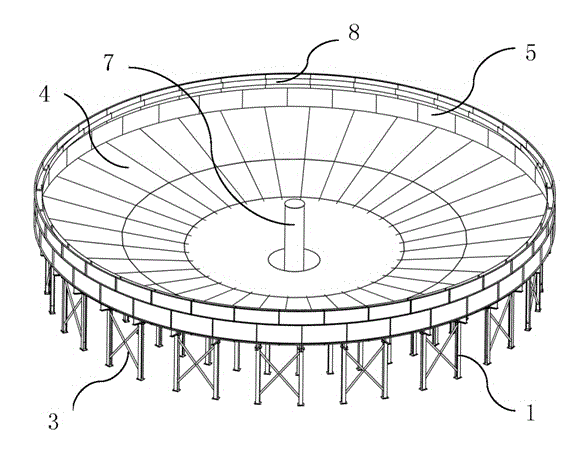

[0011] Referring to the accompanying drawings, a concentrator uses bolts to connect a steel structure pool body, including pool bottom columns 1, pool bottom beams 2, connecting rods 3, pool bottom plates 4, pool wall plates 5, bottom flow ore outlets 6, center columns 7, The overflow weir 8, the filling material 9, the steel structure tank body of the overall concentrator includes a multi-circle concentrically arranged pool bottom column 1, one end of the pool bottom column 1 is connected to the ground by anchor bolts, and the other end is connected to the pool bottom beam 2 by bolts Connection, the pool bottom columns 1 in the outer ring are connected with bolts and connecting rods 3, the upper end of the pool bottom beam 2 is connected with the pool bottom plate 4 using bolts, the pool bottom plate 4 has flange surfaces on all four sides, and two adjacent pool bottom plates Filling material 9 is added between the flange surfaces of 4, and two adjacent pool bottom plates 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com