Centrifugal pressure filtration sludge dewatering device

A filter press dehydration and sludge technology, which is applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of high water content after dehydration, low water content after dehydration, and inability to continue production and operation, and achieve water content The effect of low rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

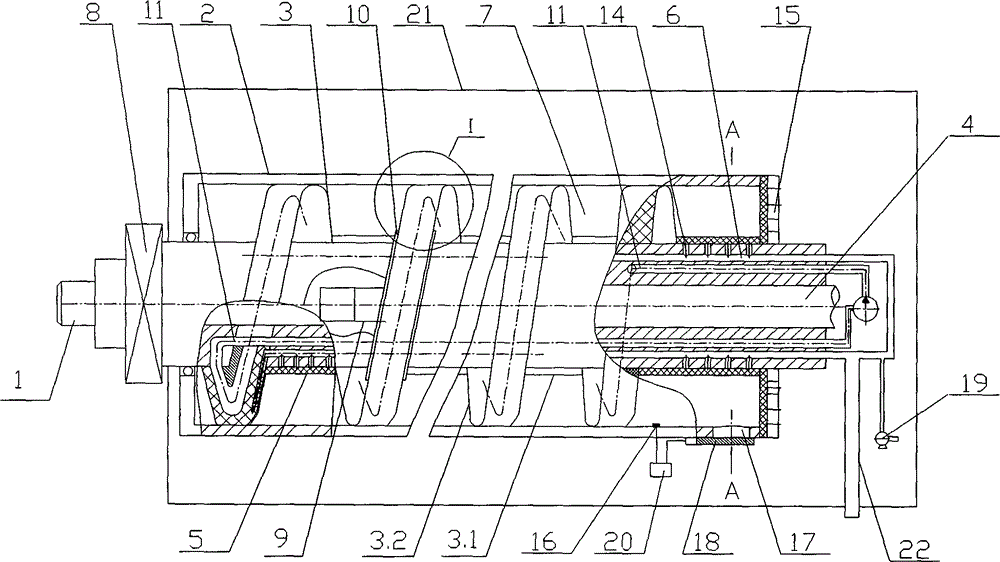

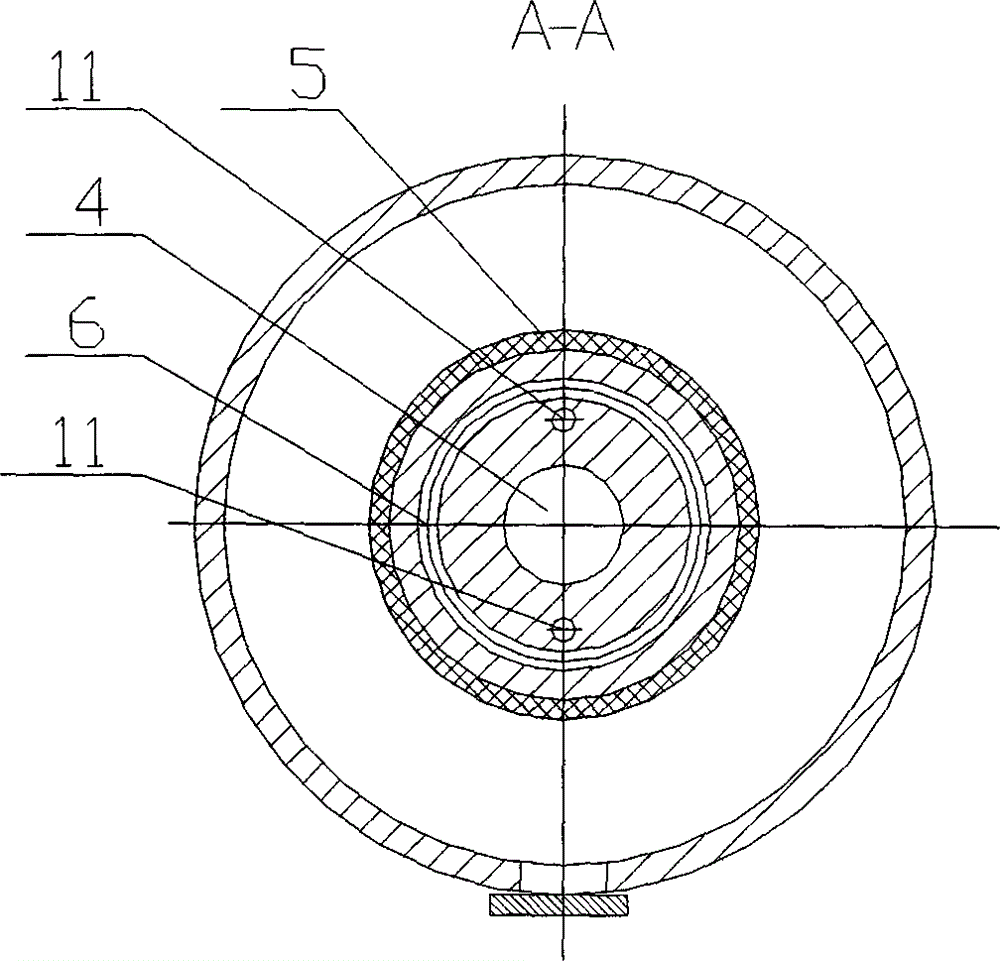

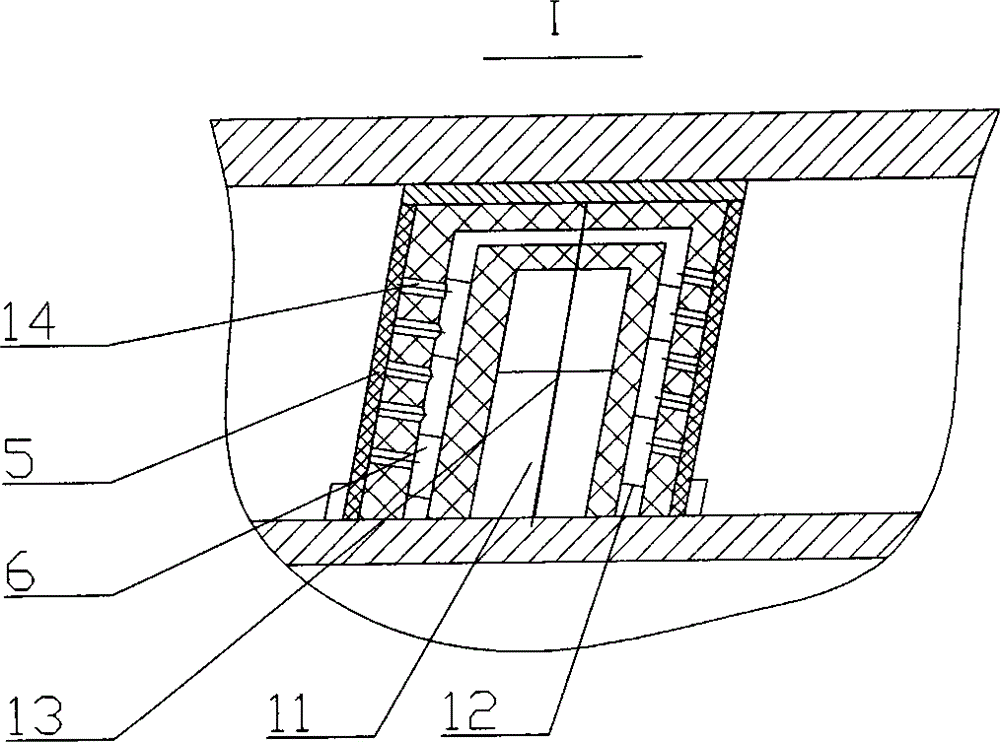

[0019] As shown in the figure, a sludge centrifugal filter press dewatering device of the present invention includes a motor 1, a drum 2 and a screw press filter 3, and the screw press filter 3 is arranged in the drum 2, and the screw press filter 3 includes The screw shaft 3.1 and the screw press blade 3.2, the screw shaft 3.1 is hollow inside and a sludge feed channel 4 is set inside, and the sludge is sent into the drum 2 through the sludge feed channel 4, and the screw press filter 3 A filter layer 5 and a drainage channel 6 are provided. The drainage channel 6 communicates with the drum 2 through the filter layer 5. The spiral filter blades 3.2 and the drum 2 form a plurality of filter chambers 7. The plurality of The filter press chamber shrinks sequentially along the direction of sludge movement.

[0020] The above technologies constitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com