Pipe fitting punching machine

A technology for punching machines and pipe fittings, applied in the field of machinery, can solve the problems of difficulty in guaranteeing punching precision, easy deformation of mandrels, short service life of pipe punching devices, etc., and achieves high punching precision, high production efficiency and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

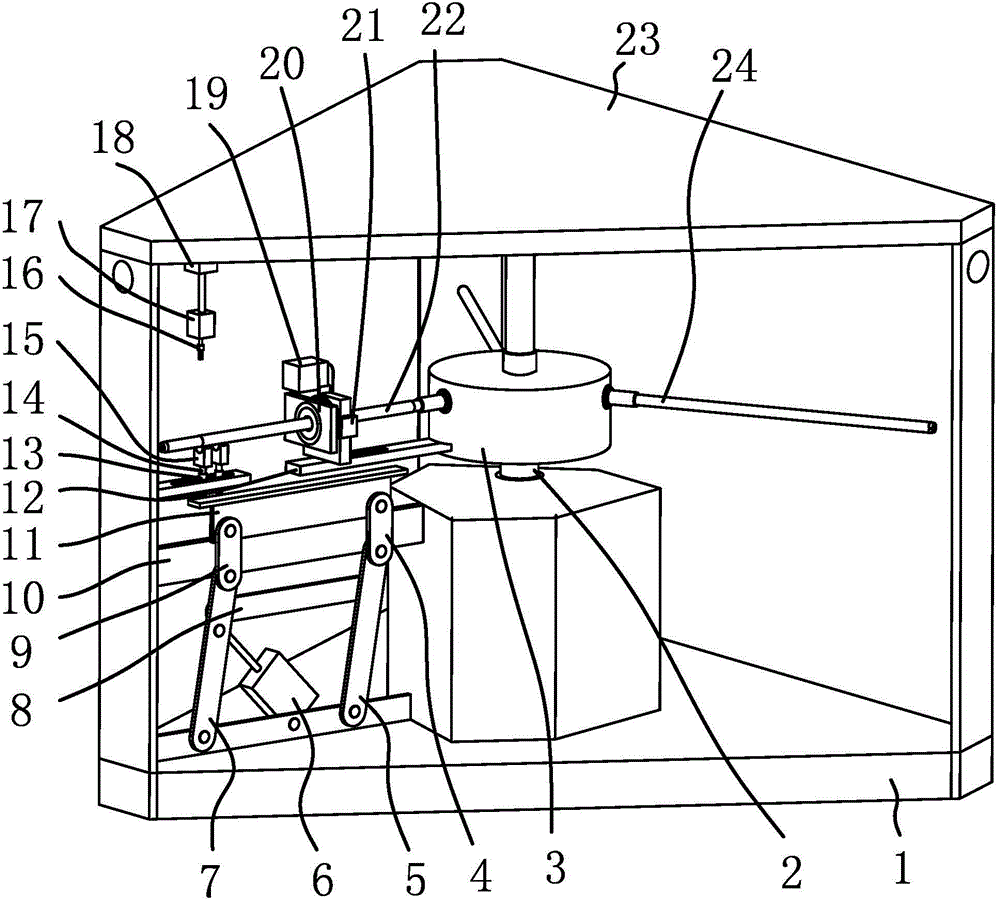

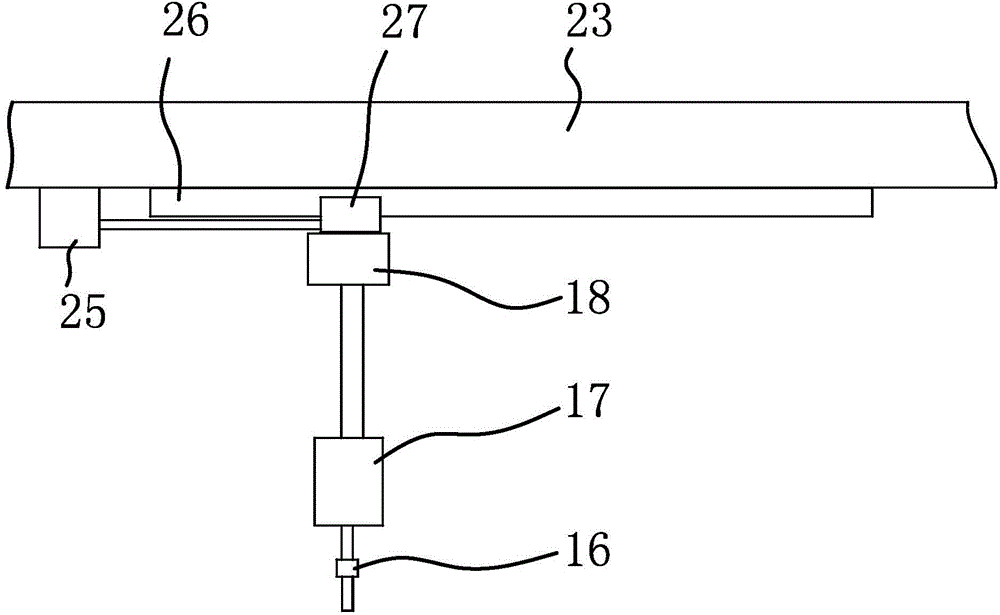

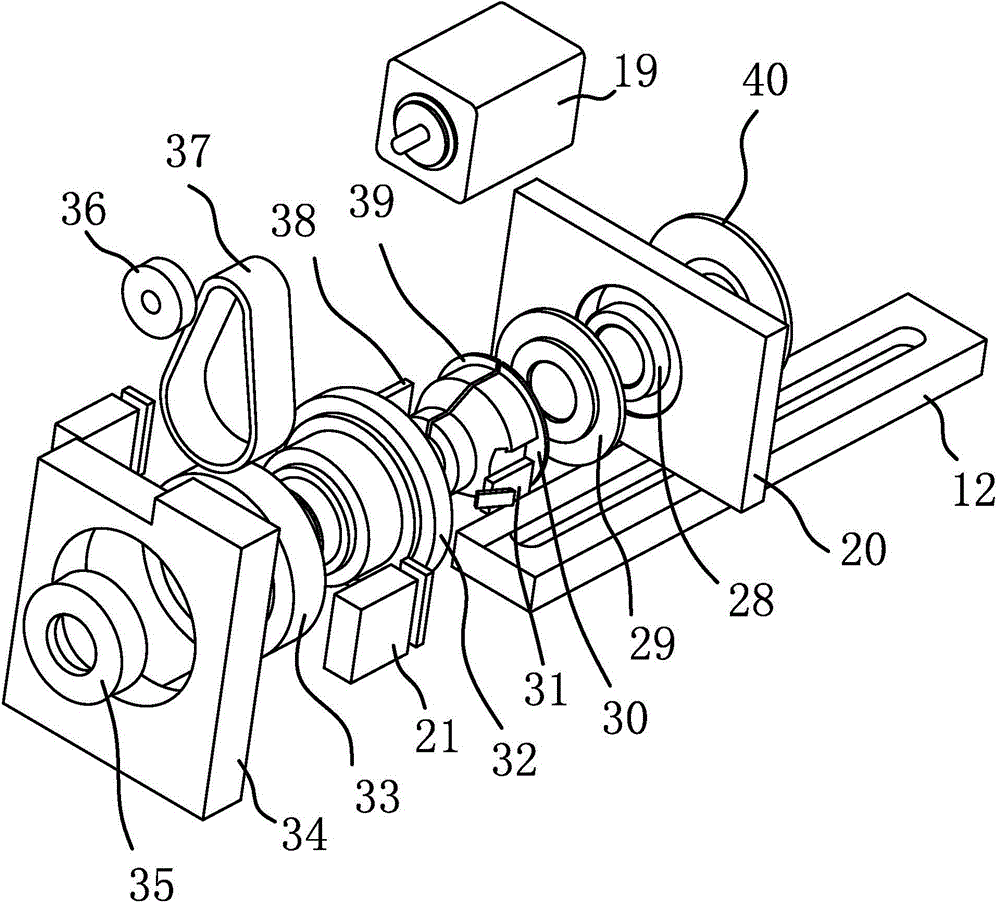

[0032] Such as figure 1 As shown, the pipe fitting drilling machine includes a base 1, on which a driving shaft 2 is fixed axially and rotated in a circumferential direction, and a lower bearing seat is fixed on the base 1, and the lower bearing seat is fixed by bolt connection On the base 1; the lower bearing seat is provided with a lower bearing, the lower end of the drive shaft 2 is pierced and fixed on the inner ring of the lower bearing, and the cooperation between the inner ring of the lower bearing and the lower end of the drive shaft 2 is a transition fit; above the base 1 A positioning plate 23 is provided, and the positioning plate 23 is fixed on the base 1 through the connecting bracket 10. The upper bearing sea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap