Rare earth magnetic material with controlled deformation of magnetic field and preparation method thereof

A magnetic material and rare earth technology, applied in the field of rare earth magnetic materials, can solve the problems of reducing alloy magnetism and hindering alloy magnetron deformation, and achieve the effects of improving magnetic properties, good mechanical properties, and large magnetic strain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

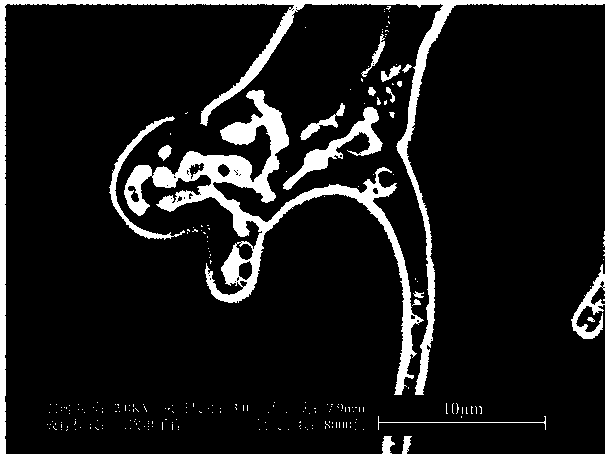

Image

Examples

Embodiment 1

[0025] The composition of the preparation is Co 42 Ni 32 Al 25.5 Dy 0.5 The rare earth magnetic material with magnetic field controllable deformation, its preparation method is as follows:

[0026] (1) Weigh respectively Co, Ni, Al, Dy with a purity of 99.9%;

[0027] (2) Put the weighed raw materials in the crucible, and use vacuum melting. The melting conditions are: a.1×10 -3 b. The melting temperature is 1300°C; c. The melting process uses magnetic stirring; d. The melting time is 0.5 hours.

[0028] (3) Rapidly solidify the alloy ingot obtained by the above-mentioned vacuum smelting, the solidification condition is: temperature 550-1200°C; time: 0.5-100 hours; vacuum degree: 1×10 -2 ~1×10 -3 MPa;

[0029] (4) Carry out vacuum annealing treatment to the above-mentioned solidified alloy rods, the treatment conditions are: temperature 550°C; time: 100 hours; vacuum degree: 1×10 -2 MPa. Then cool down to room temperature with the furnace.

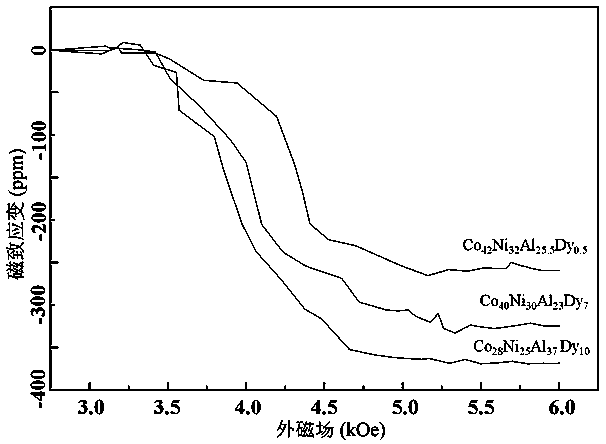

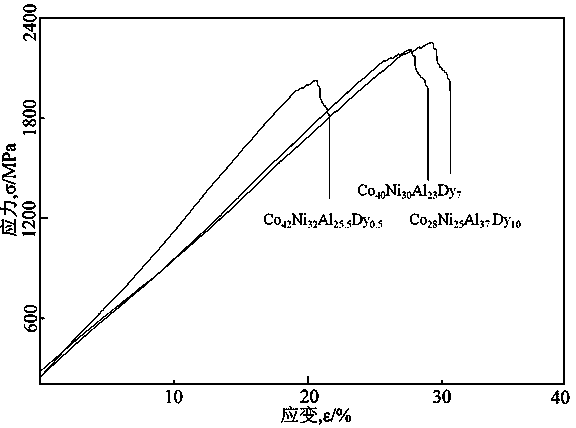

[0030] The polycrystallin...

Embodiment 2

[0032] The composition of the preparation is Co 40 Ni 30 Al 23 Dy 7 A magnetic alloy with magnetic field-driven twin martensitic deformation, the preparation method of which is as follows:

[0033] (1) Weigh respectively Co, Ni, Al, Dy with a purity of 99.9%;

[0034] (2) Put the weighed raw materials in the crucible, and use vacuum melting. The melting conditions are: a.1×10 -4 b. The melting temperature is 1400°C; c. The melting process uses magnetic stirring; d. The melting time is 1.5 hours.

[0035] (3) Rapidly solidify the alloy ingot obtained by the above-mentioned vacuum smelting, the solidification condition is: temperature 550-1200°C; time: 0.5-100 hours; vacuum degree: 1×10 -2 ~1×10 -3 MPa;

[0036] (4) Carry out vacuum annealing treatment to the above-mentioned smelted alloy ingot, the treatment conditions are: temperature 800°C; time: 70 hours; vacuum degree: 5×10 -3 MPa. Then cool down to room temperature with the furnace.

[0037] The polycrystalline sam...

Embodiment 3

[0039] The composition of the preparation is Co 28 Ni 25 Al 37 Dy 10 A magnetic alloy with magnetic field-driven twin martensitic deformation, the preparation method of which is as follows:

[0040] (1) Weigh respectively Co, Ni, Al, Dy with a purity of 99.9%;

[0041] (2) Put the weighed raw materials in the crucible, and use vacuum melting. The melting conditions are: a.1×10 -5 b. The melting temperature is 1500°C; c. The melting process uses magnetic stirring; d. The melting time is 2 hours.

[0042] (3) Rapidly solidify the alloy ingot obtained by the above-mentioned vacuum smelting, the solidification condition is: temperature 550-1200°C; time: 0.5-100 hours; vacuum degree: 1×10 -2 ~1×10 -3 MPa;

[0043] (4) Carry out vacuum annealing treatment to the above-mentioned smelted alloy ingot, the treatment conditions are: temperature 1000 ℃; time: 24 hours; vacuum degree: 1×10 -3 MPa. Then cool down to room temperature with the furnace.

[0044] The polycrystalline s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com