Special mold steel material for high-energy spiral pressure machine

A technology of screw press and die steel, applied in the field of hot forging die steel and large hammer forging die steel, can solve problems such as low efficiency, and achieve the effect of reducing production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] A special mold steel material for SPKA22400 high-energy screw press, which contains the following materials in weight percentage: carbon (C) 0.50, manganese (Mn) 1.00, silicon (Si) 0.1, chromium (Cr) 0.70, nickel (Ni ) 1.60, molybdenum (Mo) 0.25, vanadium (V) 0.15, and the rest are iron (Fe) and inevitable inclusions.

Embodiment 2

[0010] A special mold steel material for SPKA22400 high-energy screw press, which contains the following materials in weight percentage: carbon (C) 0.60, manganese (Mn) 0.70, silicon (Si) 0.40, chromium (Cr) 1.00, nickel (Ni ) 1.40, molybdenum (Mo) 0.325, vanadium (V) 0.10, and the rest are iron (Fe) and inevitable inclusions.

Embodiment 3

[0012] A special mold steel material for SPKA22400 high-energy screw press, which contains the following materials in weight percentage: carbon (C) 0.55, manganese (Mn) 0.85, silicon (Si) 0.20, chromium (Cr) 0.85, nickel (Ni ) 1.80, molybdenum (Mo) 0.40, vanadium (V) 0.125, and the rest are iron (Fe) and inevitable inclusions.

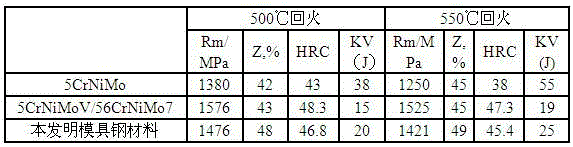

[0013] The comparison of the mechanical properties of the special mold steel material used in the SPKA22400 high-energy screw press and 5CrNiMo, 5CrNiMoV / 56CrNiMoV7 in the present invention is shown in the following table:

[0014]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com