Gravity type hydraulic breaking hammer

A hydraulic breaker, gravity type technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of complex structure, large occupied area, low impact capacity of vertical pole, etc., to achieve simple design structure and high work efficiency , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

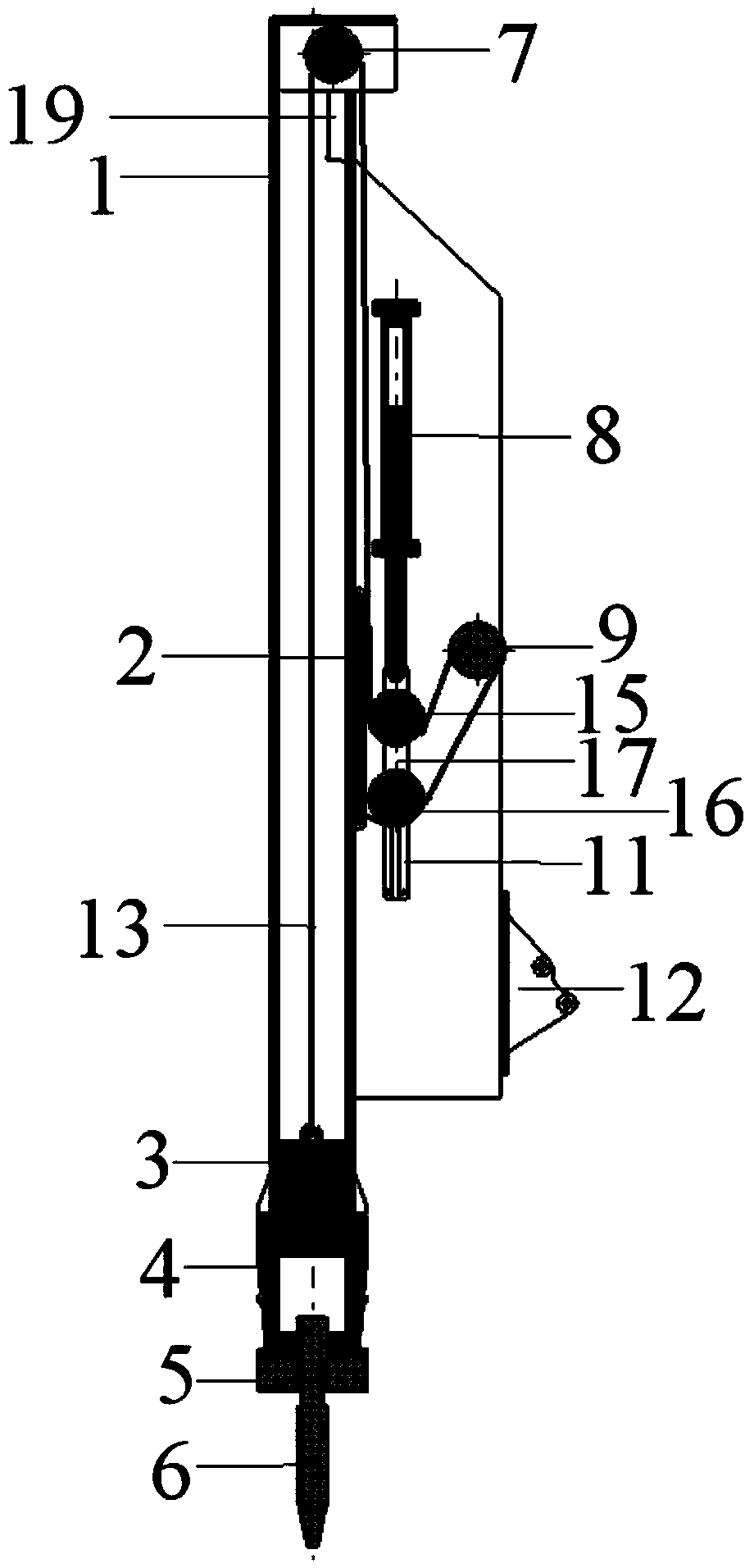

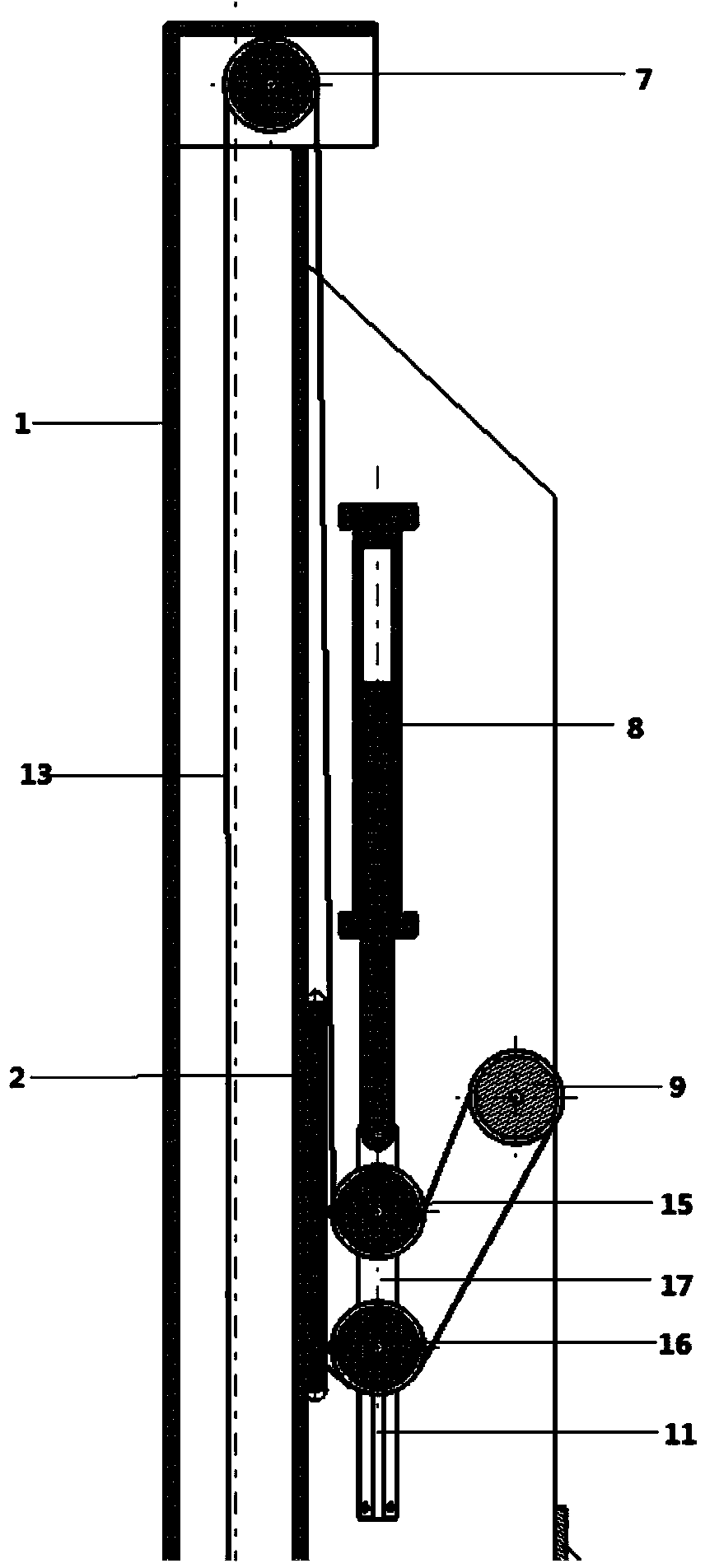

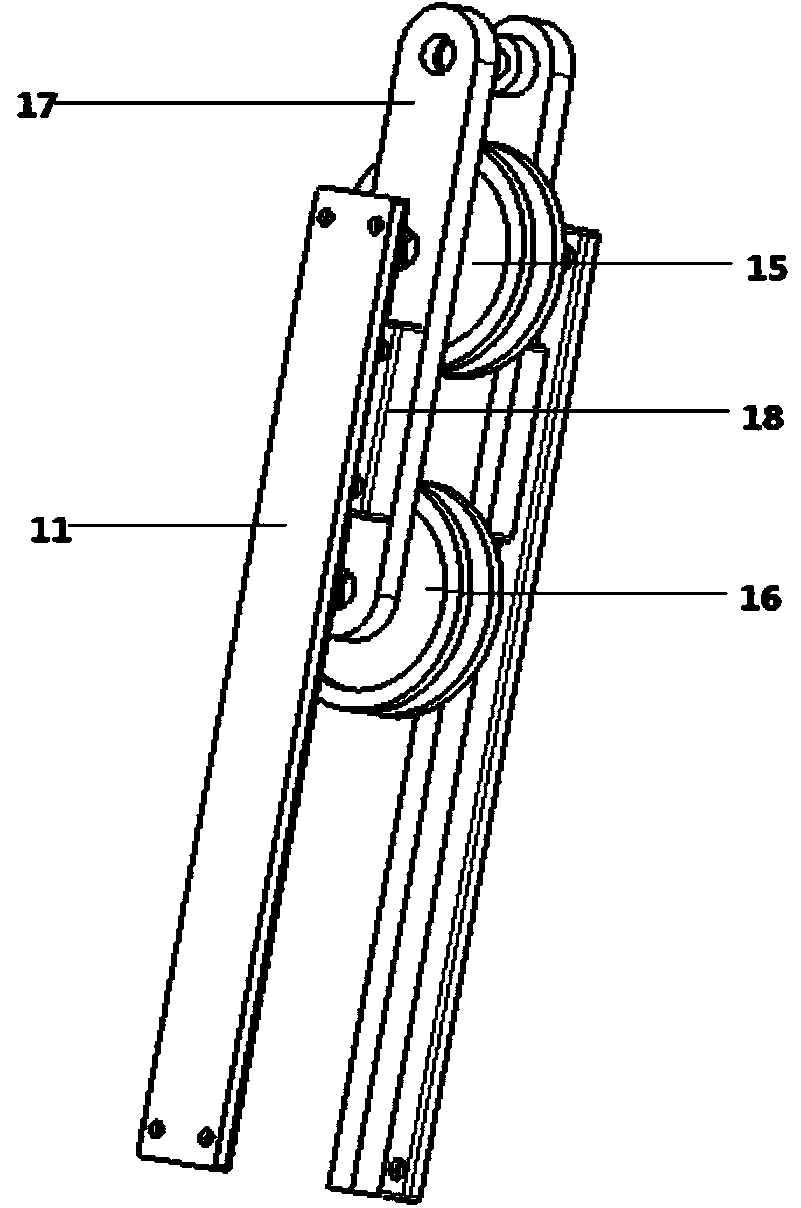

[0035] A new type of gravity hydraulic breaker, its structure is as follows Figure 1-4 As shown, including the hammer shell 1, the guide rail, the hammer shell 1 is provided with a hydraulic cylinder 8 and a pulley rotating mechanism, one side of the hammer shell 1 is provided with a guide cylinder 19, and the top of the guide cylinder 19 is provided with a top pulley 7, The lower end of the guide cylinder 19 is provided with a drill rod 6, the drill rod holder 5 is connected with the shock absorber 4 by screws, the guide cylinder 19 is provided with an impact piston 3, the upper end of the impact piston 3 is connected to the head end of the steel wire rope 13, and the tail end of the steel wire rope After bypassing the top pulley 7 and the pulley rotating mechanism successively, it is fixed on the hammer body shell 1, and the hydraulic cylinder 8 is connected with the pulley transmission mechanism. A series of several adjustment holes 2 are provided on the hammer shell 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com