Lead Body Enclosed Bearing Constrained by Layered and Continuous Constraints

A bearing and ferrule technology, which is applied to building components, building structures, earthquake-proof and other directions, can solve the problems of easy damage to the lead core, mechanical properties, small horizontal recovery force, low lateral stiffness, etc., so as to avoid plastic fracture damage. , Stable work under force and stable effect of restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

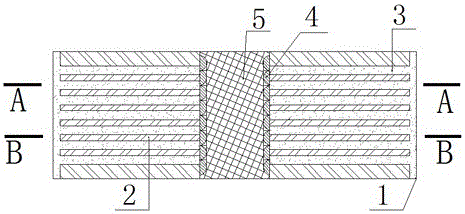

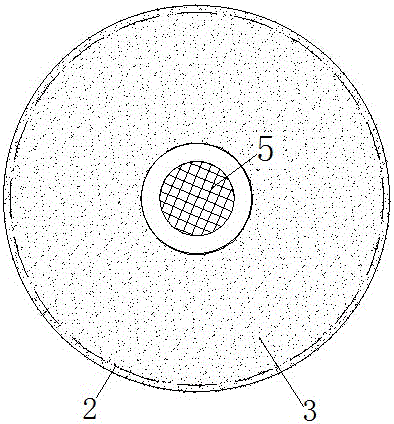

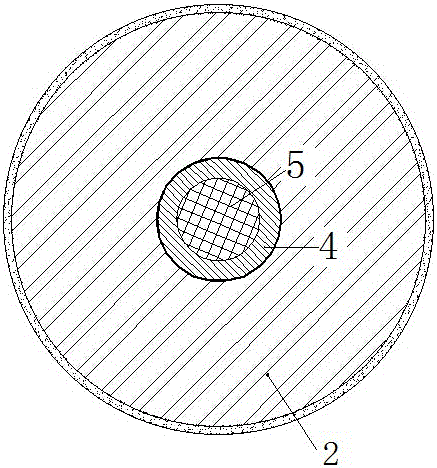

[0027]The lead-enclosed bearing that is layered and continuously restrained by hoops includes a bearing base 1 that supports engineering structures. The bearing base 1 is made of several steel plate layers 2 and rubber bonding layers 3 alternately stacked up and down. Yes, the support base 1 is provided with at least one vertical hole, and there are several restraining steel hoops 4 that are closely stacked up and down and fit closely with the hole. The restraining steel hoop 4 is a closed ring structure, and the restraining steel The inner ring wall of the hoop 4 has an arc-shaped structure, the vertical thickness of the restraining steel hoop 4 is greater than the thickness of the rubber bonding layer 3, and the upper surface of the uppermost restraining steel hoop 4 is located between the upper and lower end surfaces of the uppermost steel plate layer 2, The cavity inside the constraining steel hoop 4 is filled with an enclosing lead body 5 that fits closely with it.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com