An integrated device for oil, gas and water treatment with double-layer cavity and full gravity balance

A gravity balance, oil-gas-water technology, applied in the treatment of hydrocarbon oil, combined devices, and multi-stage series-connected refining processes, etc., can solve the problems of high processing energy consumption, insufficient processing capacity, energy consumption, etc., and achieve simple process operation , The effect of ingenious internal structure and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

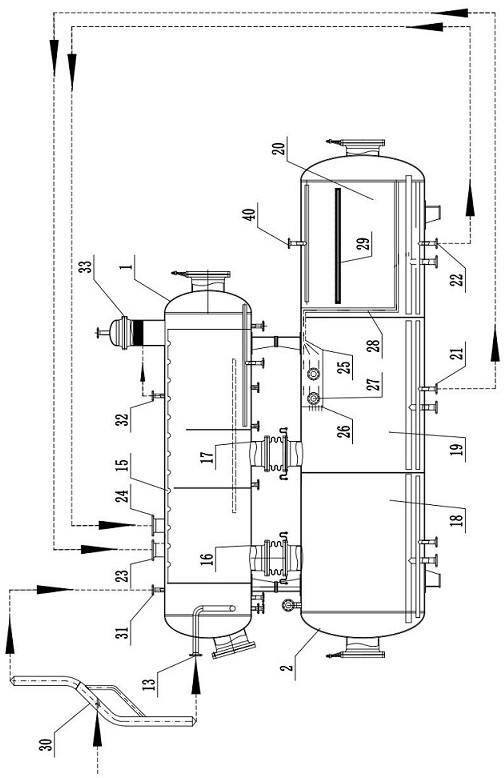

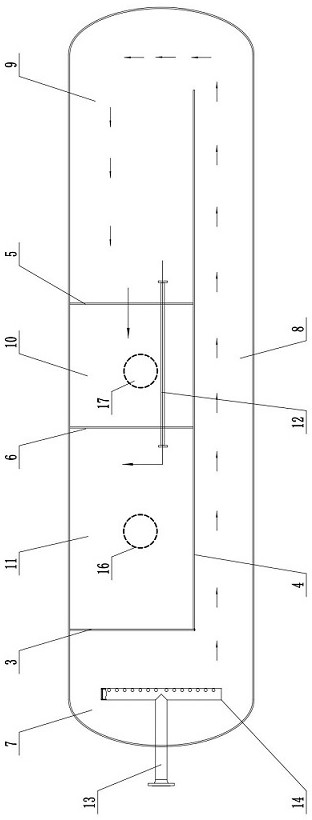

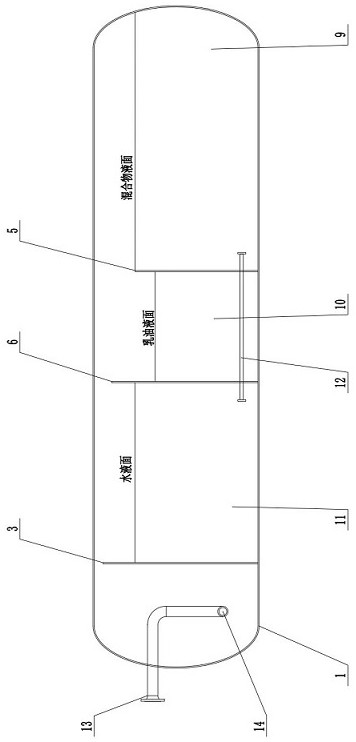

[0051] An integrated device for oil, gas and water treatment with double-layer cavity full gravity balance, comprising an upper tank 1 and a lower tank 2; the upper tank 1 is located above the lower tank 2.

[0052] The upper tank 1 is provided with a blocking weir plate 3; the blocking weir plate 3 is provided with a separation weir plate 4; a liquid inlet chamber 7 is formed between the front end of the upper layer tank 1 and the blocking weir plate 3; A diversion channel 8 is formed between the weir plate 3 , the separation weir plate 4 and the inner wall of the upper tank 1 ; an overflow weir plate 5 and an overflow prevention plate 6 are sequentially arranged in the diversion channel 8 .

[0053] An oil-water mixing chamber 9 is formed between the guide channel 8 and the overflow weir plate 5 .

[0054] An emulsified oil cavity 10 is formed between the overflow weir plate 5 and the overflow prevention plate 6 .

[0055] A water collection chamber 11 is formed between the...

Embodiment 2

[0086] The specific difference between embodiment 2 and embodiment 1 is:

[0087] The upper end of the blocking weir plate 3 and the separation weir plate 4 is sealed and connected with the inner wall of the upper end of the upper tank 1; a cyclone separator 33 and a gas phase outlet 32 are arranged above the oil-water mixing chamber 9; the cyclone separation The inlet of the device 33 communicates with the gas phase outlet 32 , and the outlet of the cyclone separator 33 communicates with the oil-water mixing chamber 9 .

[0088] Through this design, the flow channel of the gas phase passes through the diversion channel 8 and then enters the cyclone separator 33 , preventing the liquid contained in the gas from dripping into the emulsified oil chamber 10 and the water collection chamber 11 .

[0089] Simultaneously, the internal circulation heating originally adopted in the settling clean oil chamber 19 and the electric dehydration chamber 20 is changed to external circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com