Patents

Literature

39results about How to "Stable work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

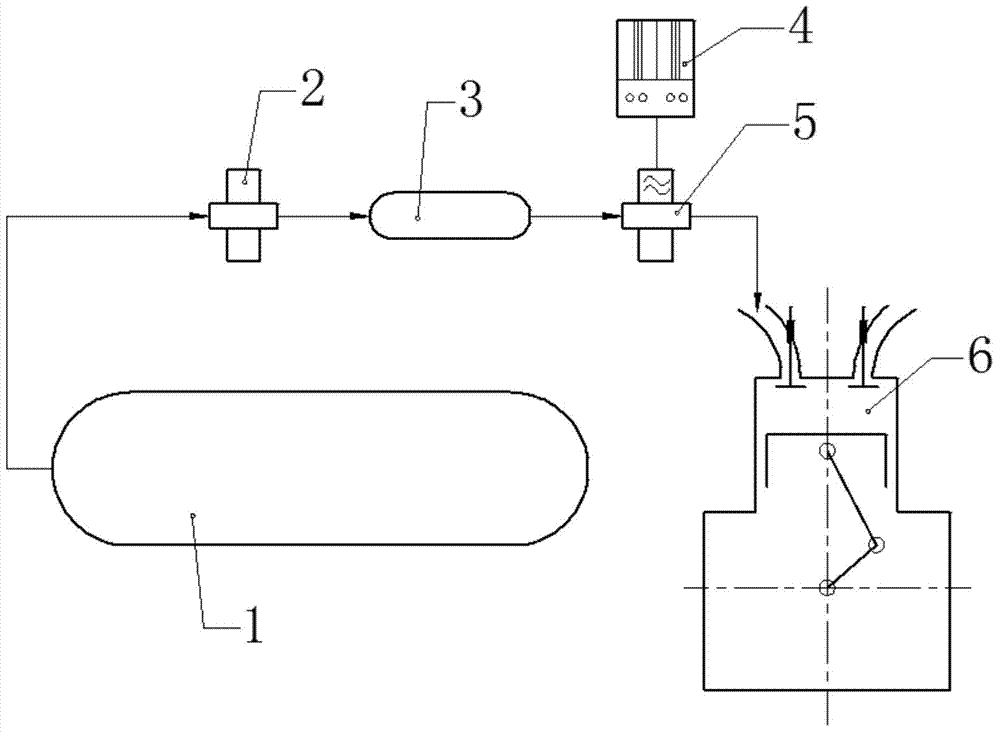

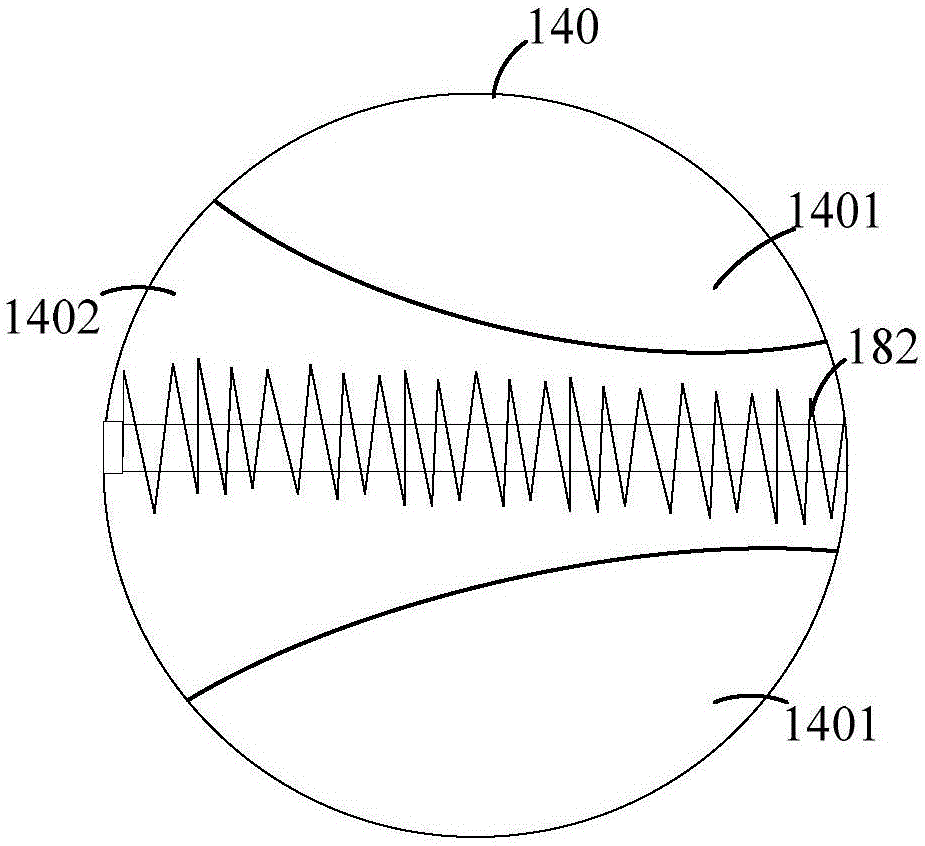

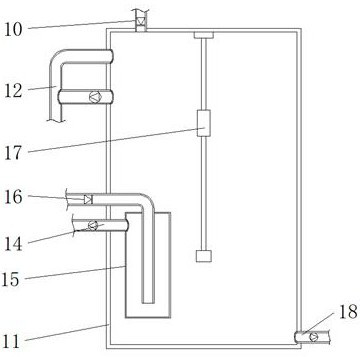

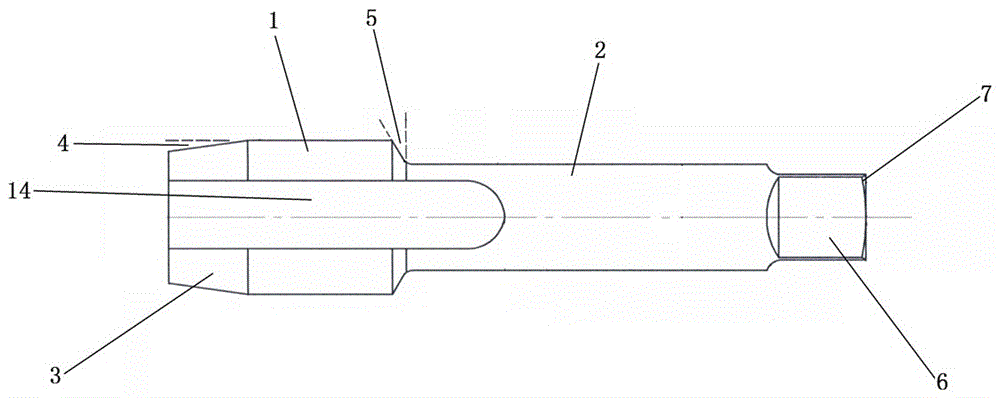

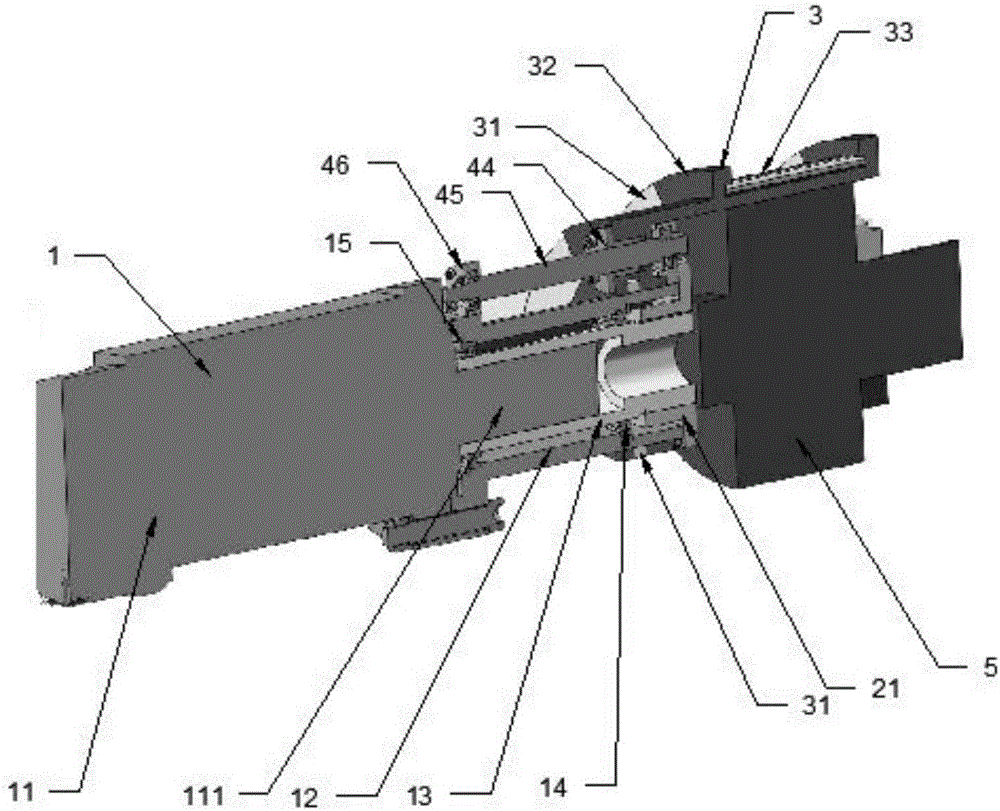

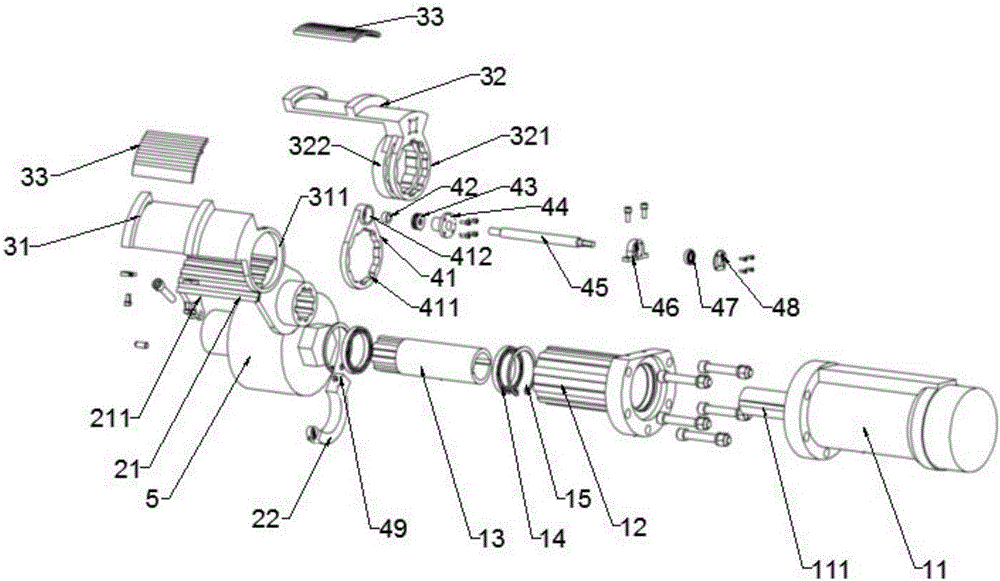

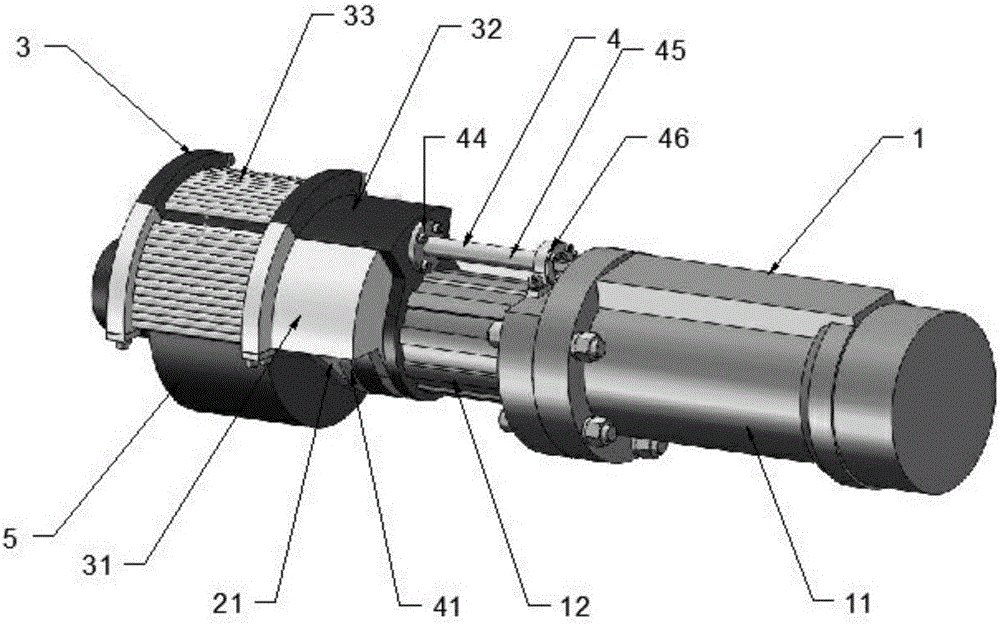

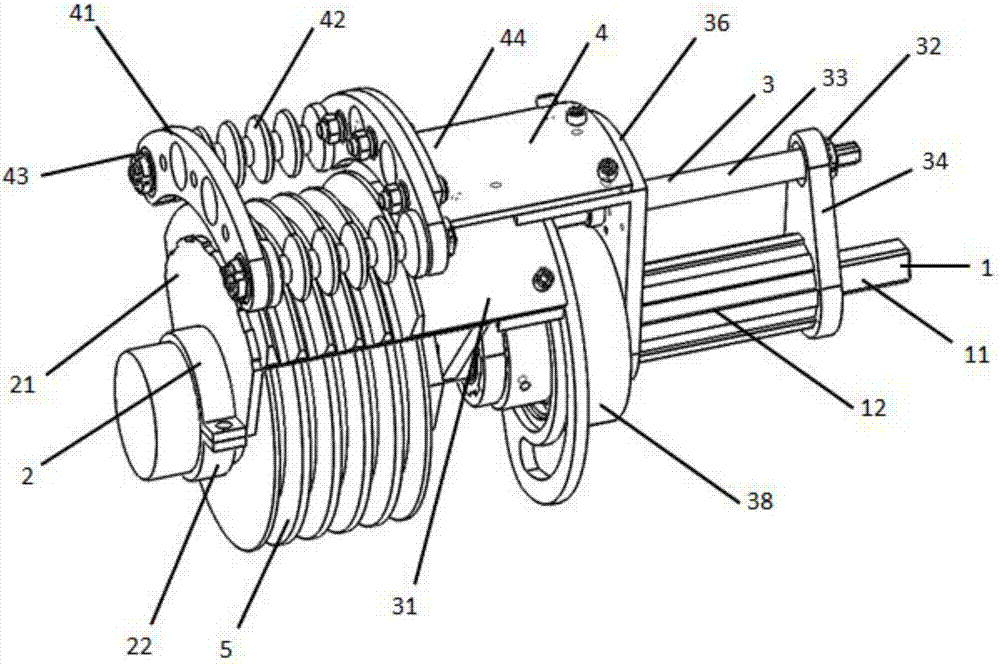

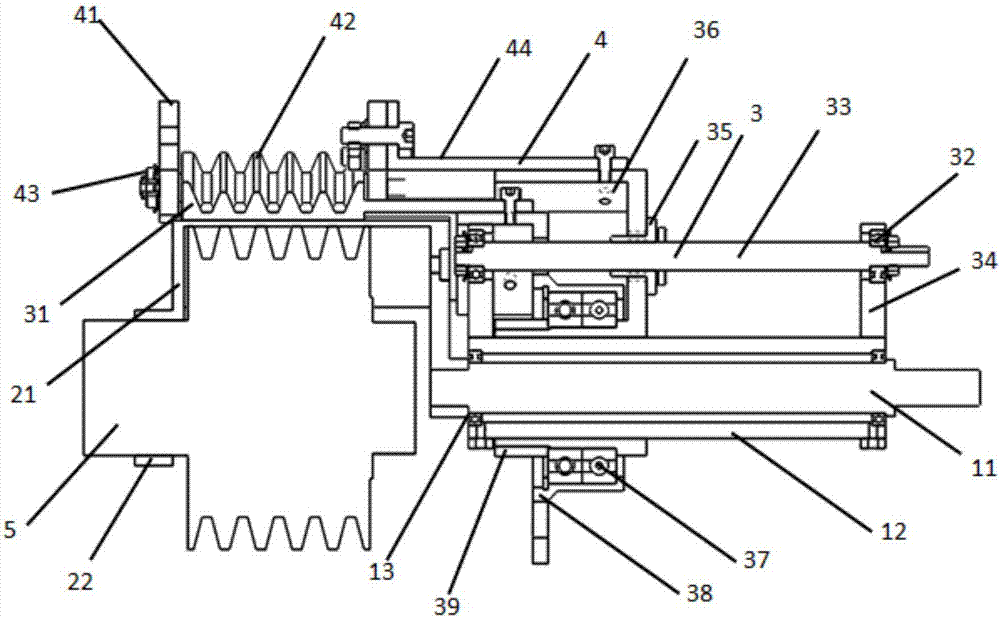

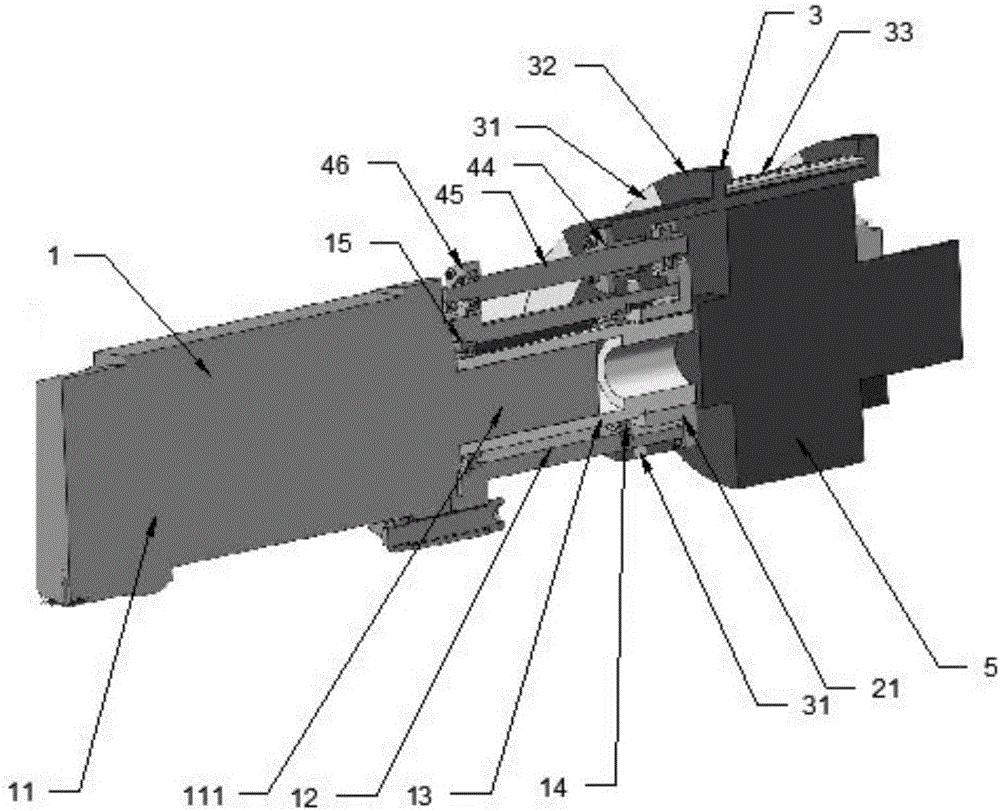

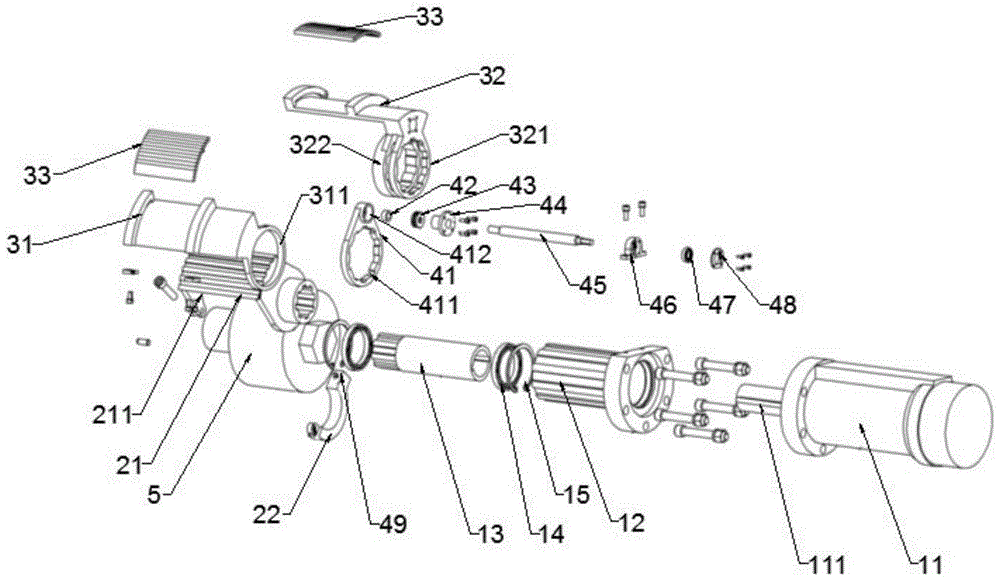

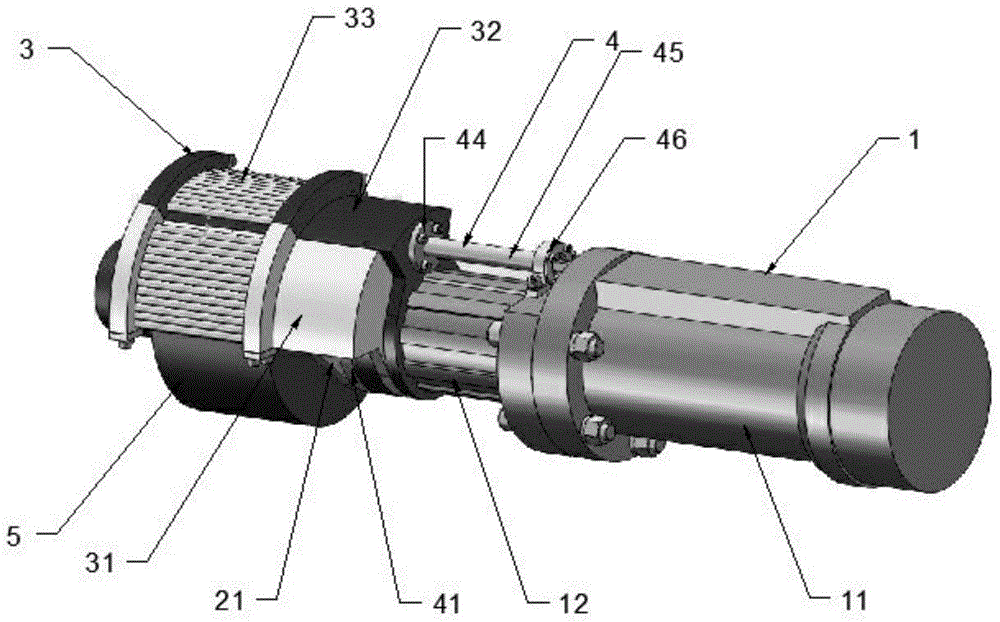

Piston type air-powered engine system

InactiveCN104295321AWork process is stableReduce noiseMachines/enginesSafety/regulatory devicesHigh pressureInternal combustion engine

The invention provides a piston type air-powered engine system capable of providing power for a vehicle, an engineering machine, a power generation device and the like and belongs to the field of power machinery. The piston type air-powered engine system utilizes gas stored in a high-pressure gas tank, and the gas is buffered and then is fed into an air cylinder through a gas distribution mechanism to push a piston to do work. Compared with a piston type internal combustion engine, a piston type air-powered engine is stable in working doing process and small in noise. The piston type air-powered engine is a two-stroke engine, namely adopts an intake work-doing stroke and an exhaust stroke, the operation process of the piston type air-powered engine is mainly a compressed gas expansion work-doing process and is a physical change process, and no exhaust pollution exists.

Owner:BEIHANG UNIV

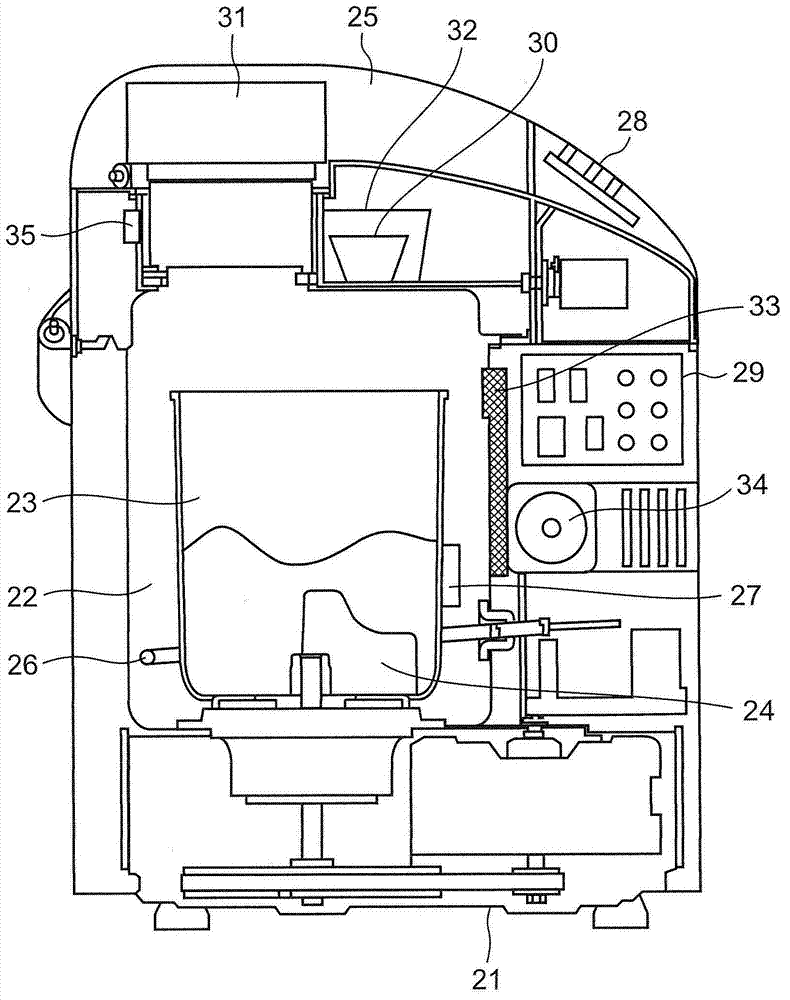

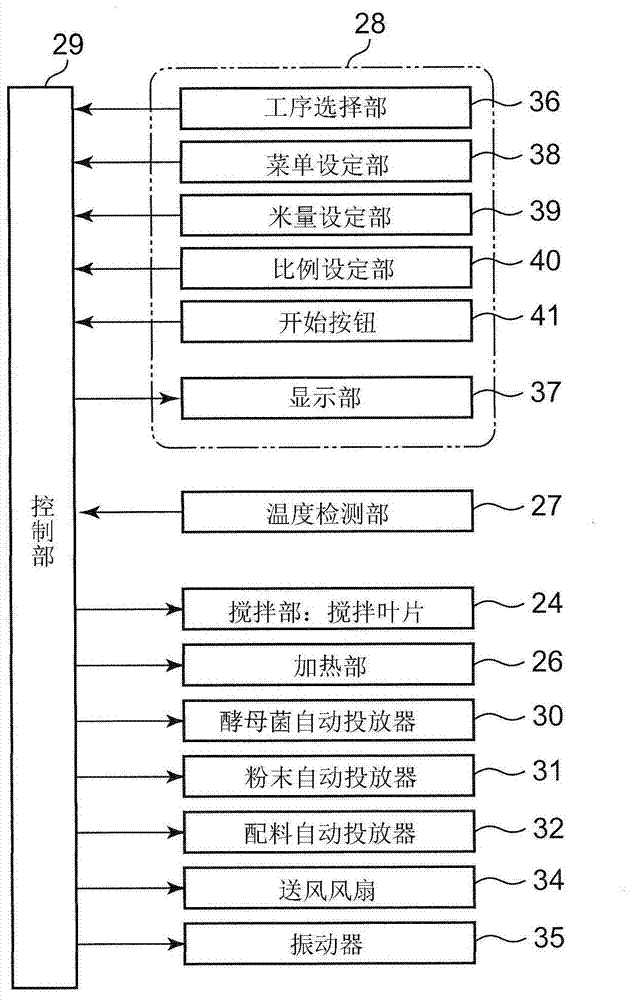

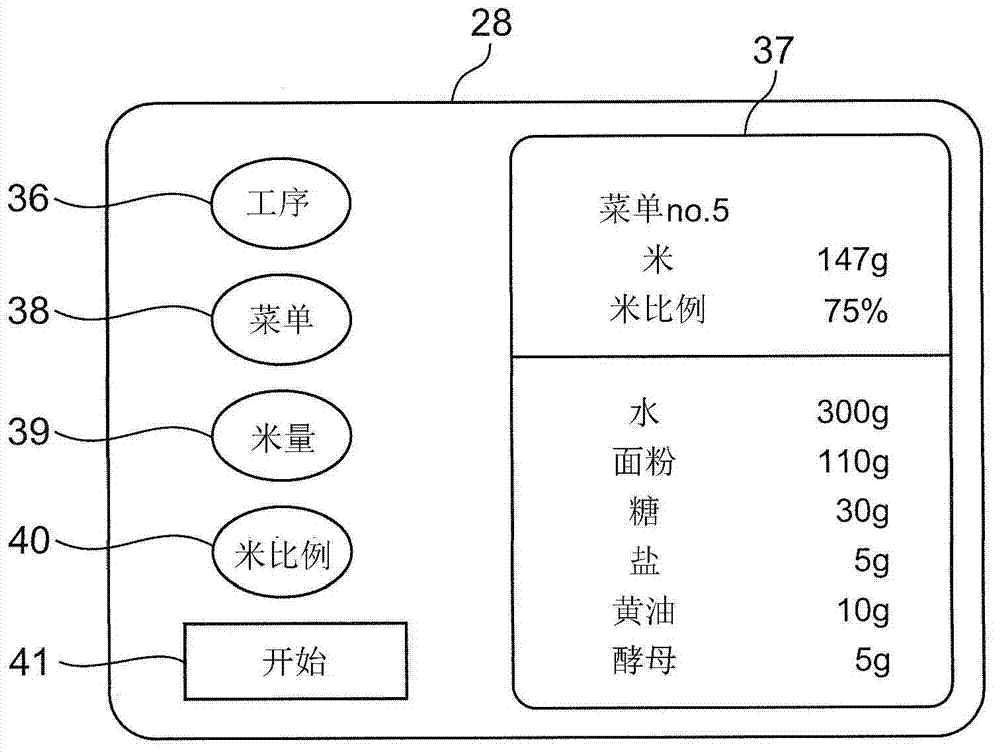

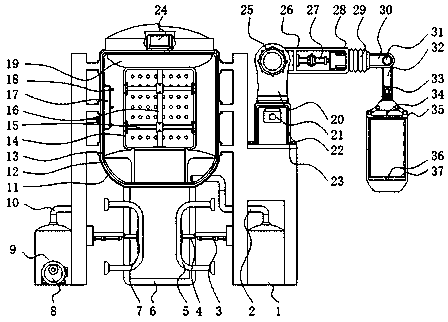

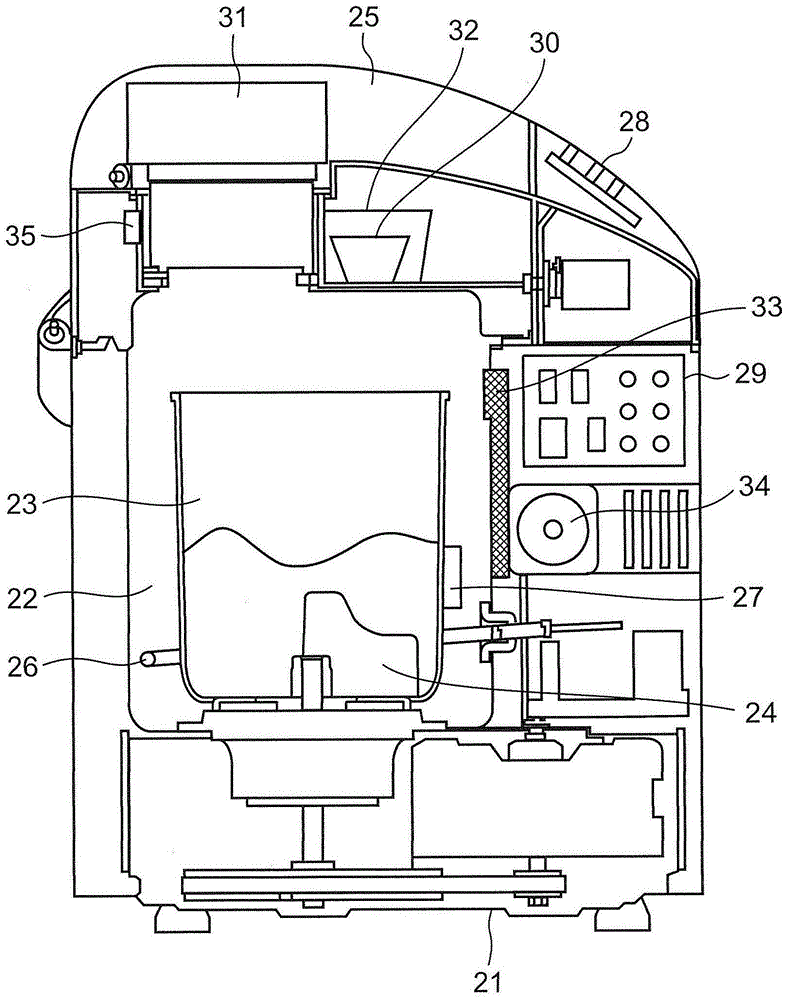

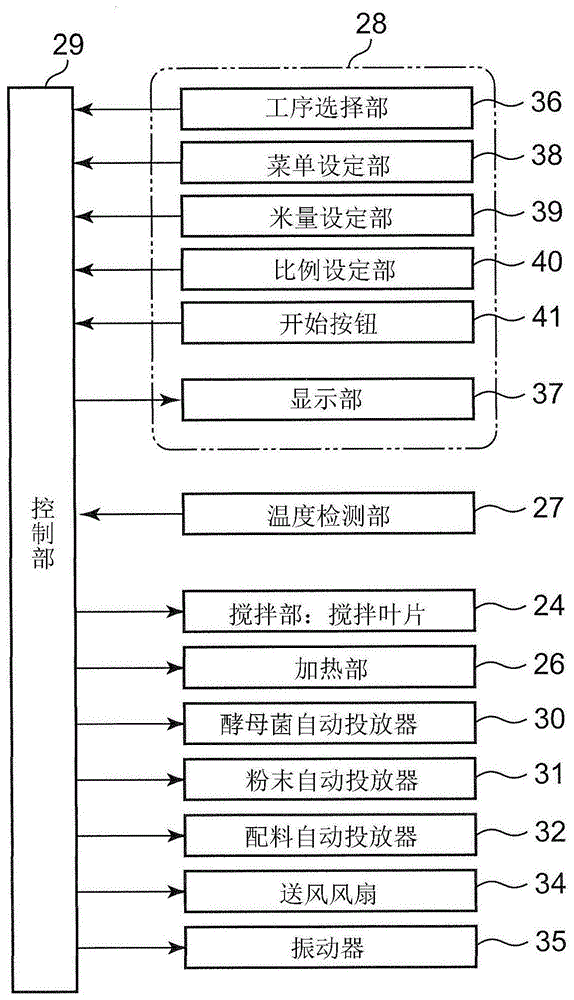

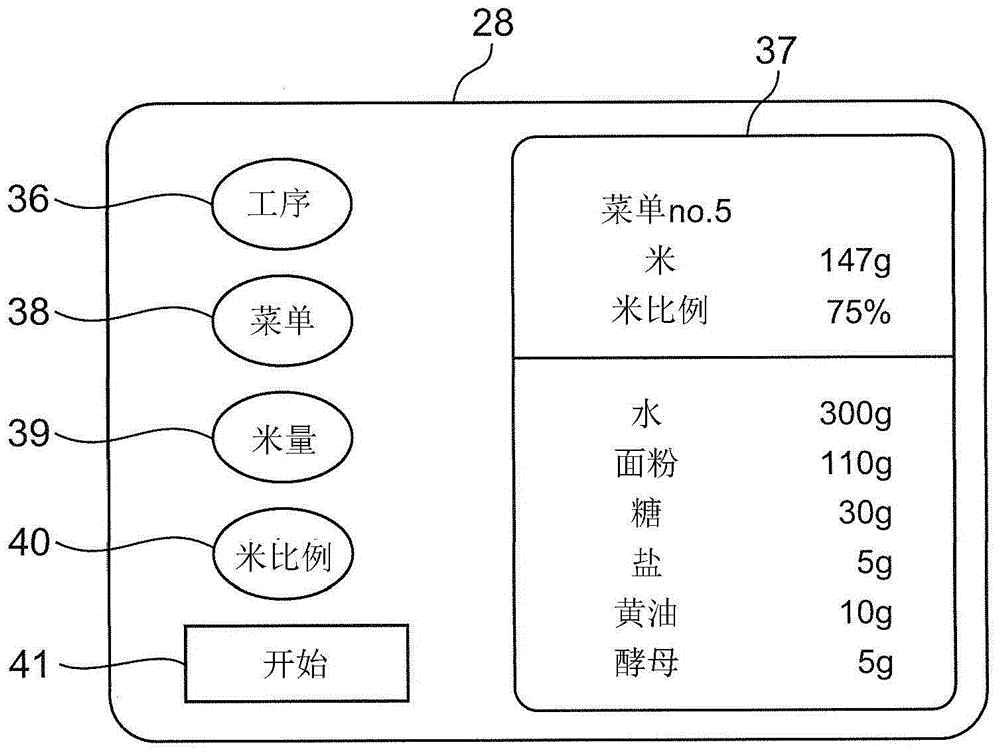

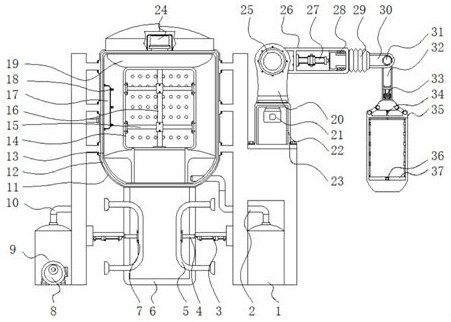

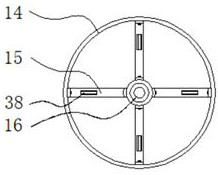

Auto brad maker

The invention provides an auto brad maker, by which rice paste is made, and the rice paste is used to make rice bread and is obtained by regulating gelatinization of rice starch, and all rice starch molecule after absorbing water will not get into gel state because of heat change including temperature of enzyme activity. The steps is as following: a control part (29) controls heating to a heating part (26) and controls driving to a stirring part (24) respectively; and the temperature controlled by the heating part is set to the temperature of enzyme activity to produce rice paste, so as to make a rice bread.

Owner:PANASONIC CORP

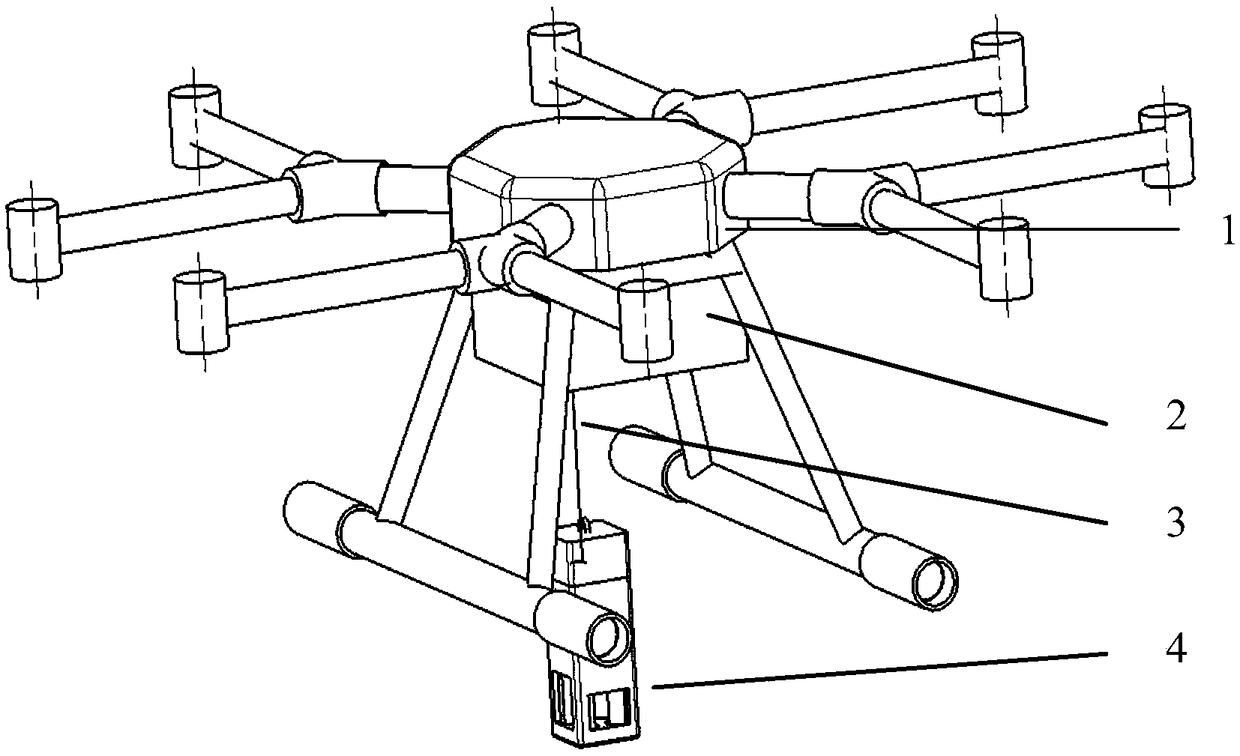

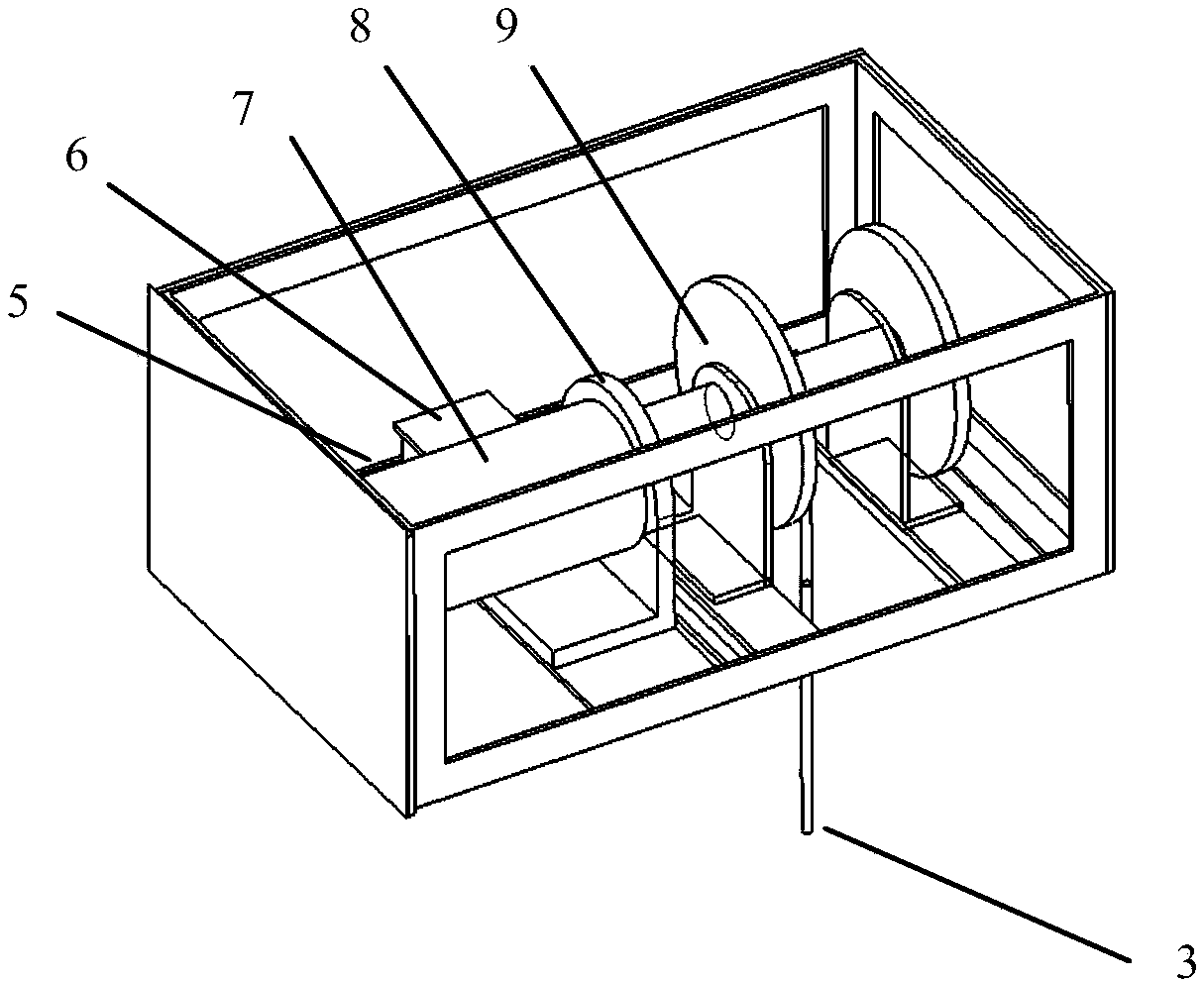

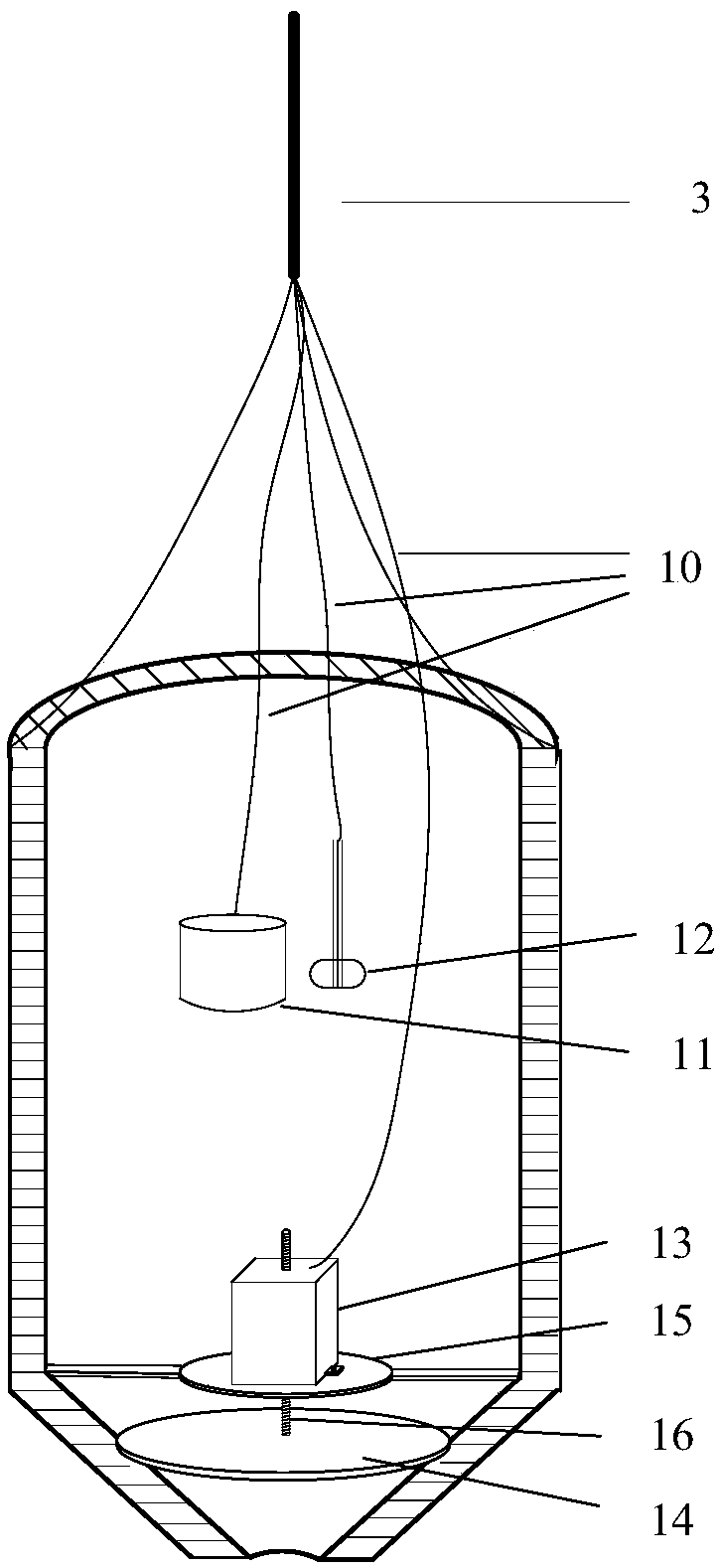

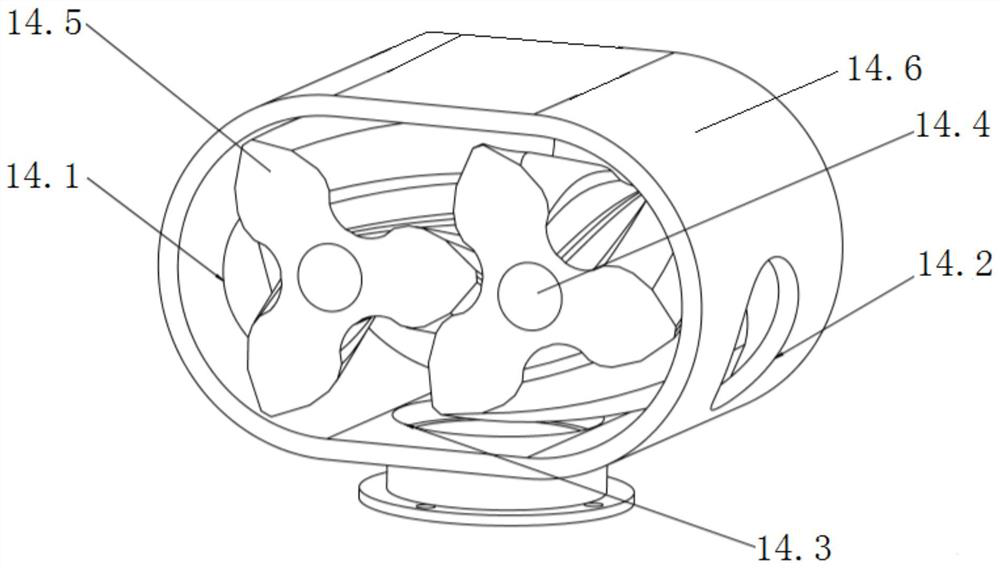

Unmanned water quality sampling and detecting system and method

PendingCN109060421AReal-time online detectionEasy to sampleWithdrawing sample devicesWater qualityEngineering

An unmanned water quality sampling and detecting system is provided for continuous and repeated detection and sampling in different depths and different areas for a long time, and comprises a drone, acontrol box, a pull wire and a sampling tube, wherein the control box is internally provided with a battery, a circuit control module, a lifting motor, a motor bracket and a reel; a sampling cylinderis particularly designed with uncovered top and conical bottom, and contains a sensor group, a water pressure gauge, a sealing motor and a sealing cover, and the water quality is sampled by controlling the sealing motor to open and close the sealing cover; at the same time, a core chip of a main control unit of the system uses a low-power device, and the main control unit detects the water depthdata of the water pressure gauge and controls the opening / closing of the sensor group, thereby greatly improving continuous working hours. Through the set of devices, the water quality can be on-linemeasured, recorded and automatically sampled several times in succession under different water depth conditions.

Owner:INST OF ENVIRONMENTAL MEDICINE & OCCUPATIONAL MEDICINE ACAD OF MILITARY MEDICINE ACAD OF MILITARY SCI

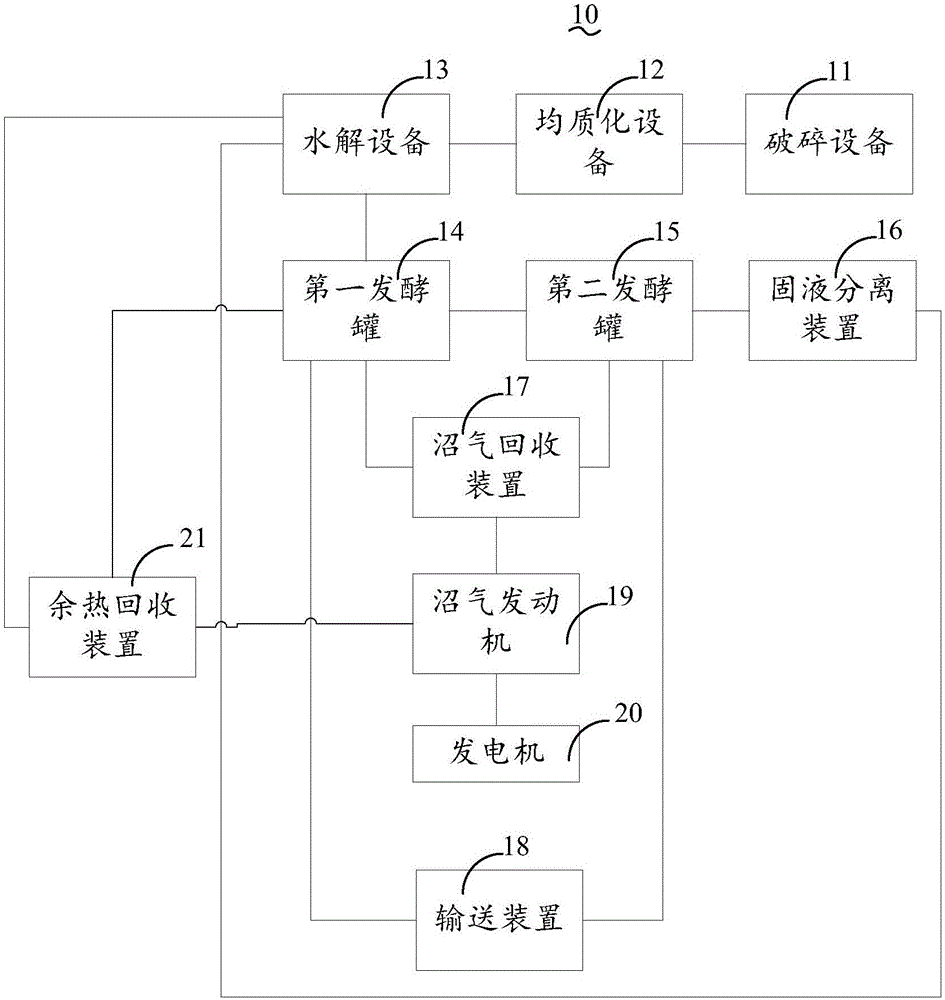

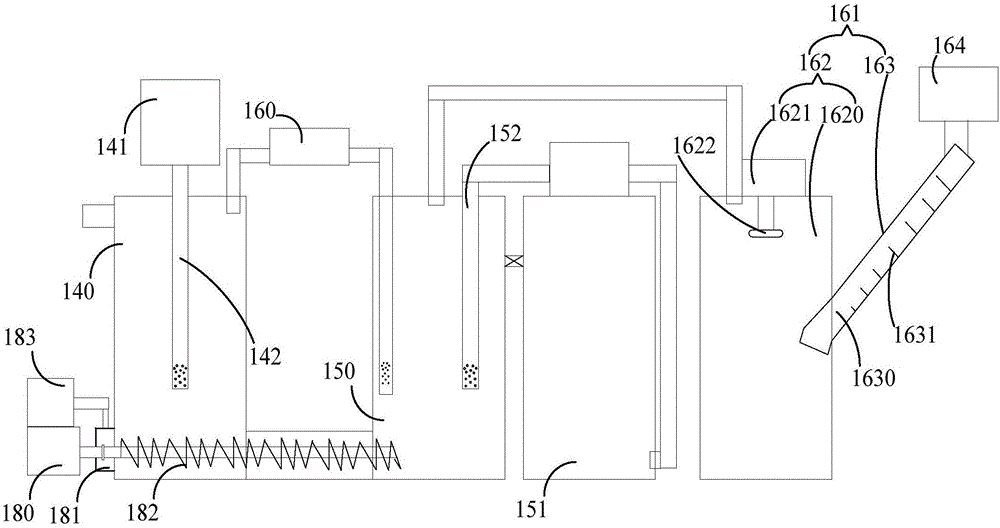

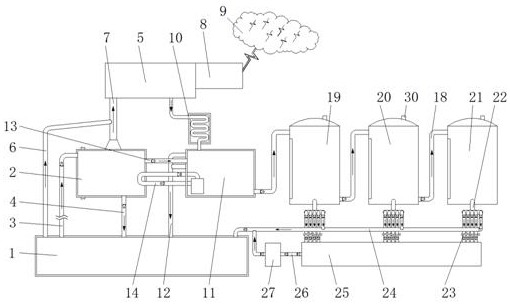

Biogas power generation system

InactiveCN106520523AStable workStable work power generationBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasElectric energy

The invention discloses a biogas power generation system, which comprises a biogas preparing and purifying system, a biogas engine, an electric generator and a waste heat recovery device, wherein the biogas preparing and purifying system is composed of crushing equipment, homogenizing equipment, hydrolysis equipment, a first fermentation tank, a second fermentation tank, a biogas recovery device and a solid-liquid separating device. The crushing equipment and the homogenizing equipment are connected; the homogenizing equipment and the hydrolysis equipment are connected; the hydrolysis equipment and the first fermentation tank are connected; the first fermentation tank is additionally connected to the second fermentation tank; the biogas recovery device is connected to the first fermentation tank, the second fermentation tank and the biogas engine; the biogas engine is connected to the electric generator and the waste heat recovery device; and the solid-liquid separating device is connected to the first fermentation tank, the second fermentation tank and the hydrolysis equipment. Stable biogas, from which hydrogen sulfide, carbon dioxide and water are removed, is outputted to the biogas engine from the biogas preparing and purifying system in the biogas power generation system, so that the biogas engine can work stably by virtue of the biogas provided by the biogas recovery device and the electric generator can be driven to stably work to generate electric energy.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

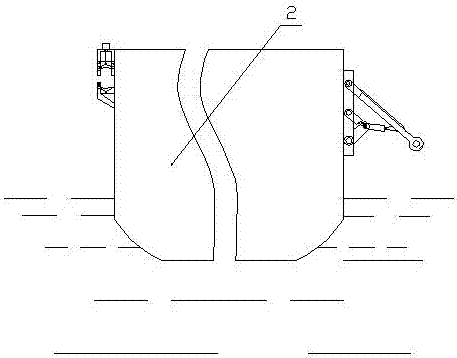

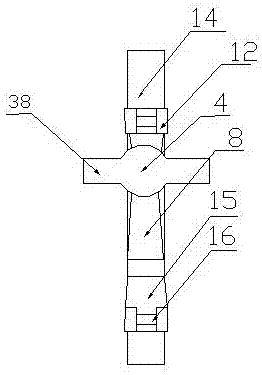

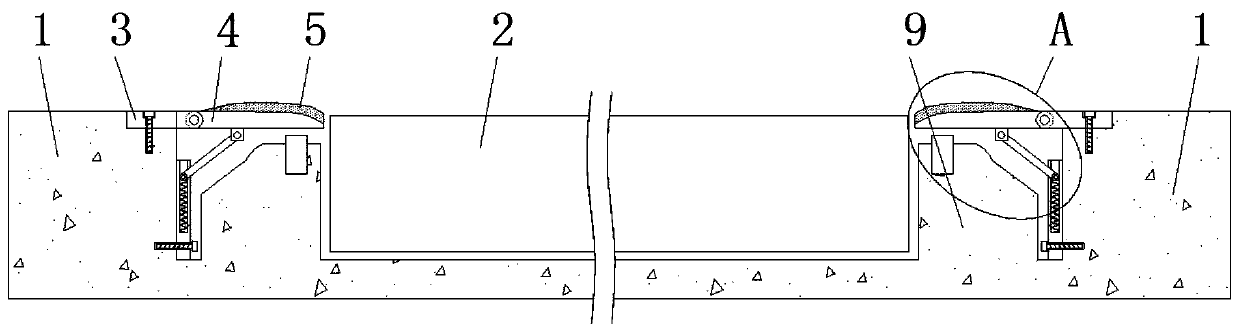

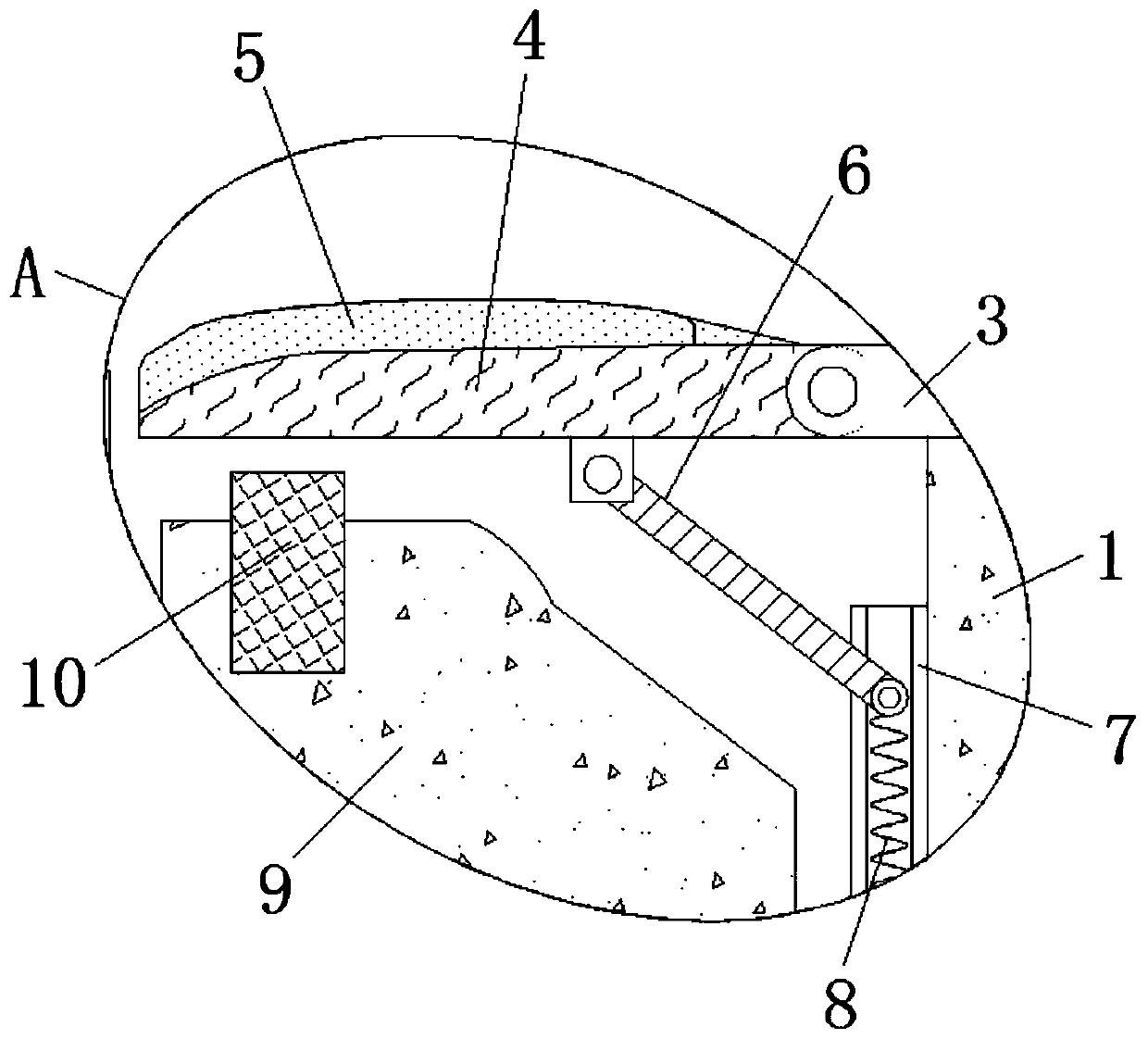

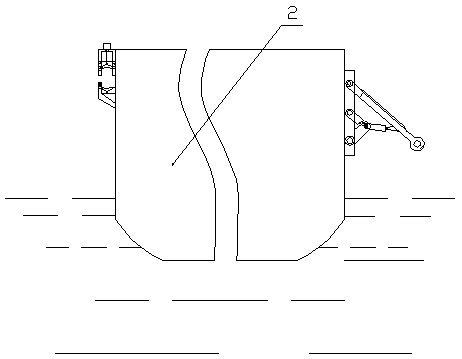

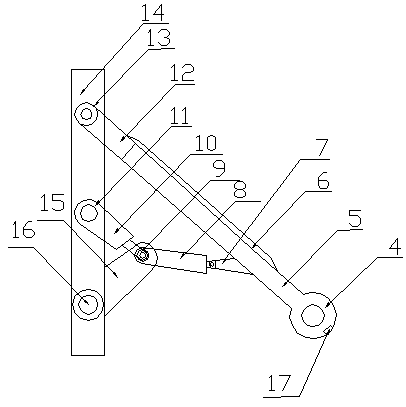

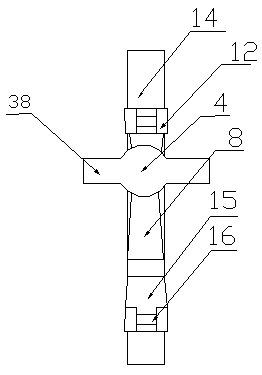

Boat connecting and disconnecting device and method thereof

ActiveCN107399408AWork quicklyStable workFloating buildingsHydrodynamic/hydrostatic featuresMarine engineeringControl system

The invention relates to a boat connecting and disconnecting device and a method thereof. The boat connecting and disconnecting device comprises a central control system, a plurality of connecting mechanisms and a plurality of tightening mechanisms. The connecting mechanisms and the tightening mechanisms are arranged on the two sides of boats, the connecting mechanisms and the tightening mechanisms on any side of the boats are arranged at equal intervals, and the central positions of the connecting mechanism and the central positions of the tightening mechanisms are located on the same horizontal line. The central control system is formed by a PLC and a Beidou navigation system. Each connecting mechanism comprises a connecting plate, a connecting arm, a supporting arm, a crank rod and a lifting arm. Each tightening mechanism is composed of a fastening assembly and a positioning assembly, wherein the positioning assembly is installed under the fastening assembly, and when the fastening assembly and the positioning assembly are installed, the distance between the fastening assembly and the positioning assembly is greater than the outer diameter of a ball protrusion on the right of the corresponding connecting arm. The boat connecting and disconnecting device is reasonable in structure and convenient to use, the method is advanced and scientific, and through the boat connecting and disconnecting device and the method, the boats can be effectively connected and disconnected.

Owner:YANGZHOU UNIV

Source management and supervision acquisition terminal

InactiveCN110410639AGuaranteed accuracyQuick installationNon-rotating vibration suppressionClosed circuit television systemsEngineeringInformation acquisition

The invention discloses a source management and supervision acquisition terminal. The terminal comprises a concrete bottom plate and an outer connecting block, the middle part of the inner side of theconcrete bottom plate is provided with a wagon balance, and a fixed plate which is fixedly connected with the concrete bottom plate is arranged on the outer side of the wagon balance. The inner sideof the fixed plate is connected with a buffer plate, and a deceleration pad adheres to the outer side of the buffer plate. The bottom of the buffer plate is connected with a supporting rod, a spring is installed inside a limiting mechanism, the outer connecting block is installed on the outer side of the concrete bottom plate, an outer clamping plate is arranged on the outer side of an installingrod, a connecting groove is formed in the middle of an inner clamping plate, a convex block is fixed to the outer side of a locating block, a frame plate is fixed to the outer side of a lantern ring,and an outer connecting plate is arranged on the outer side of the frame plate. According to the source management and supervision acquisition terminal, the accuracy of information acquisition can beensured, rapid installation is facilitated, meanwhile, the production operation cost is reduced, and long-term effective stable working use can be guaranteed.

Owner:郑州今迈衡器有限公司

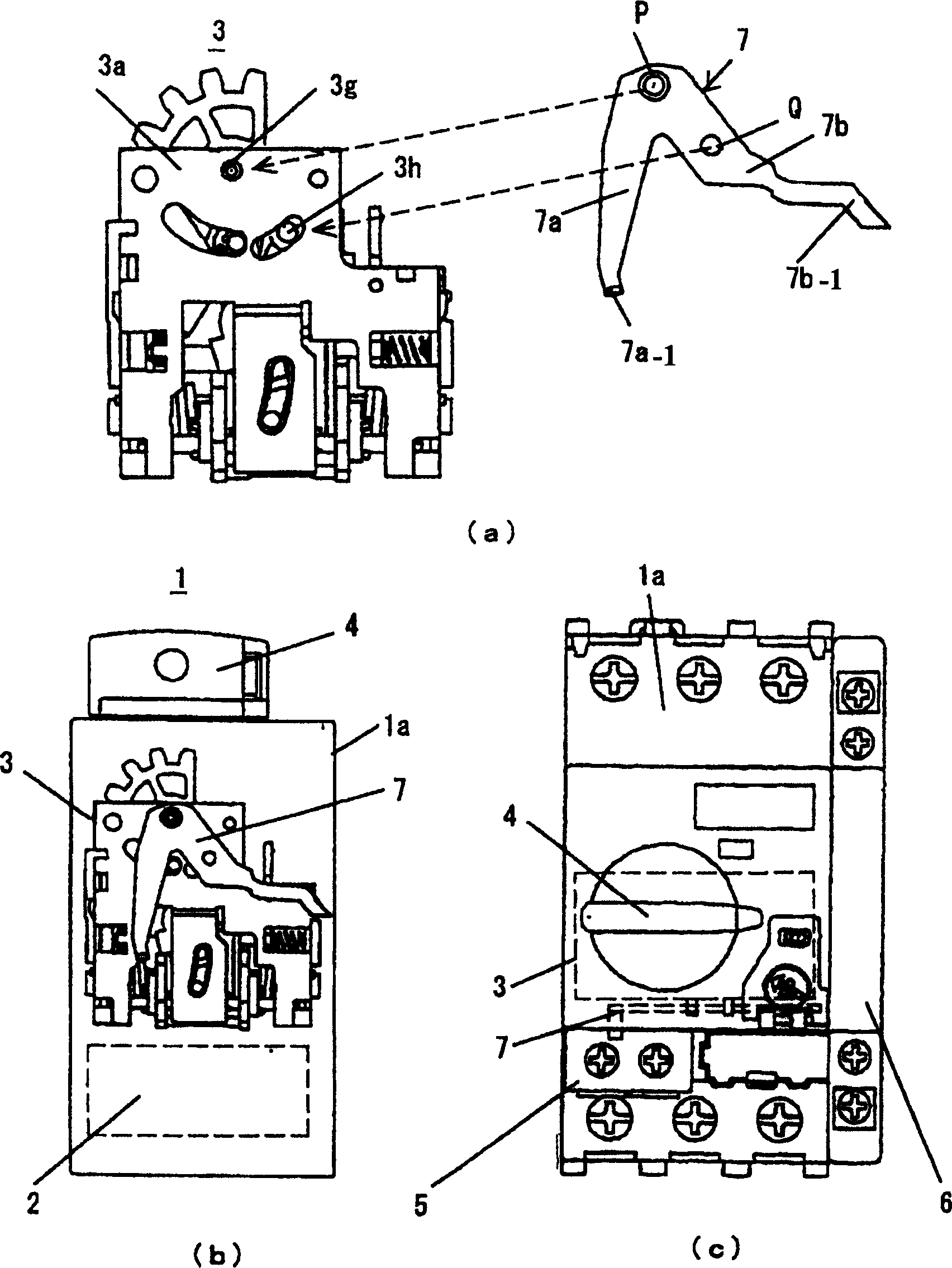

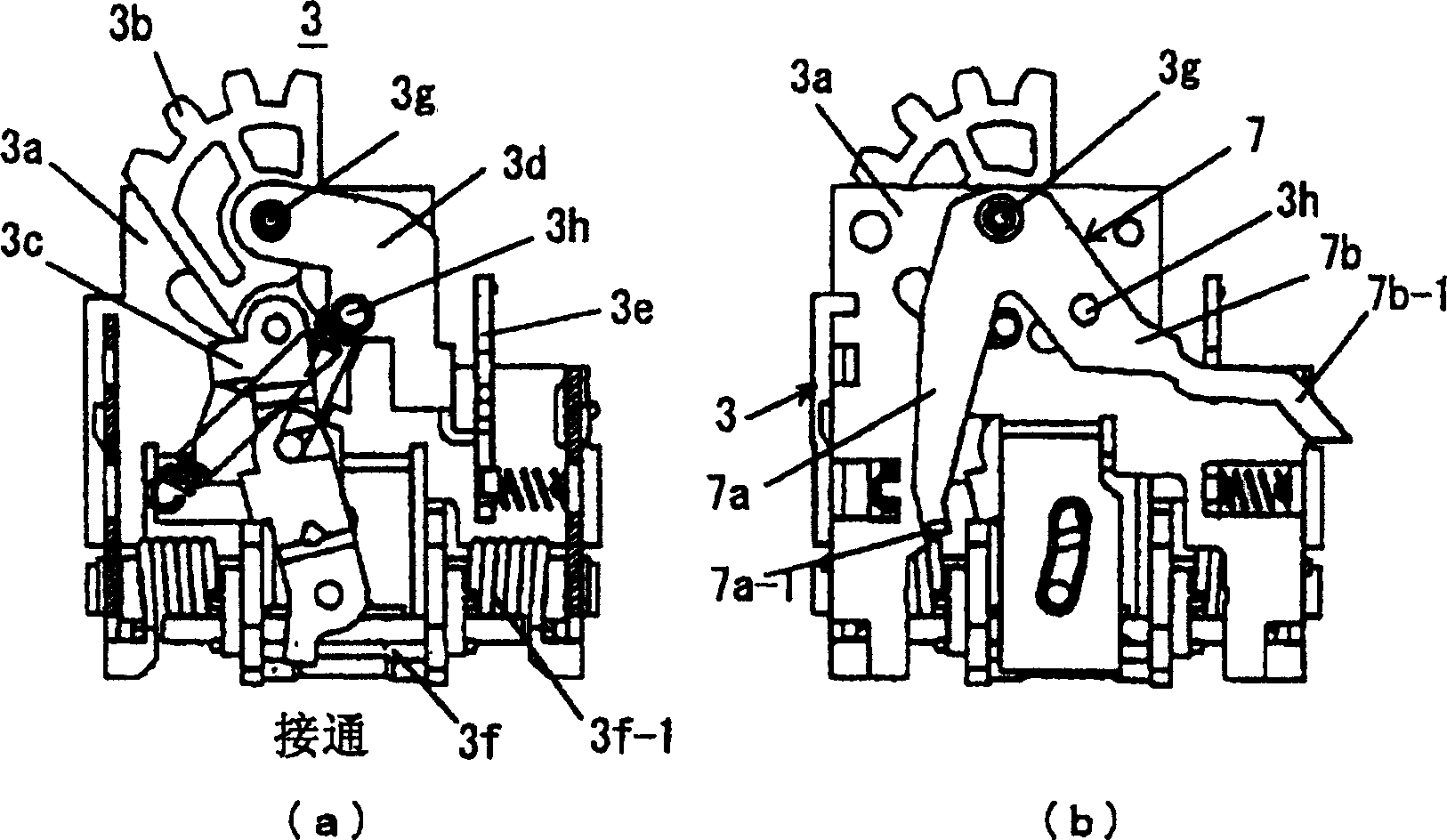

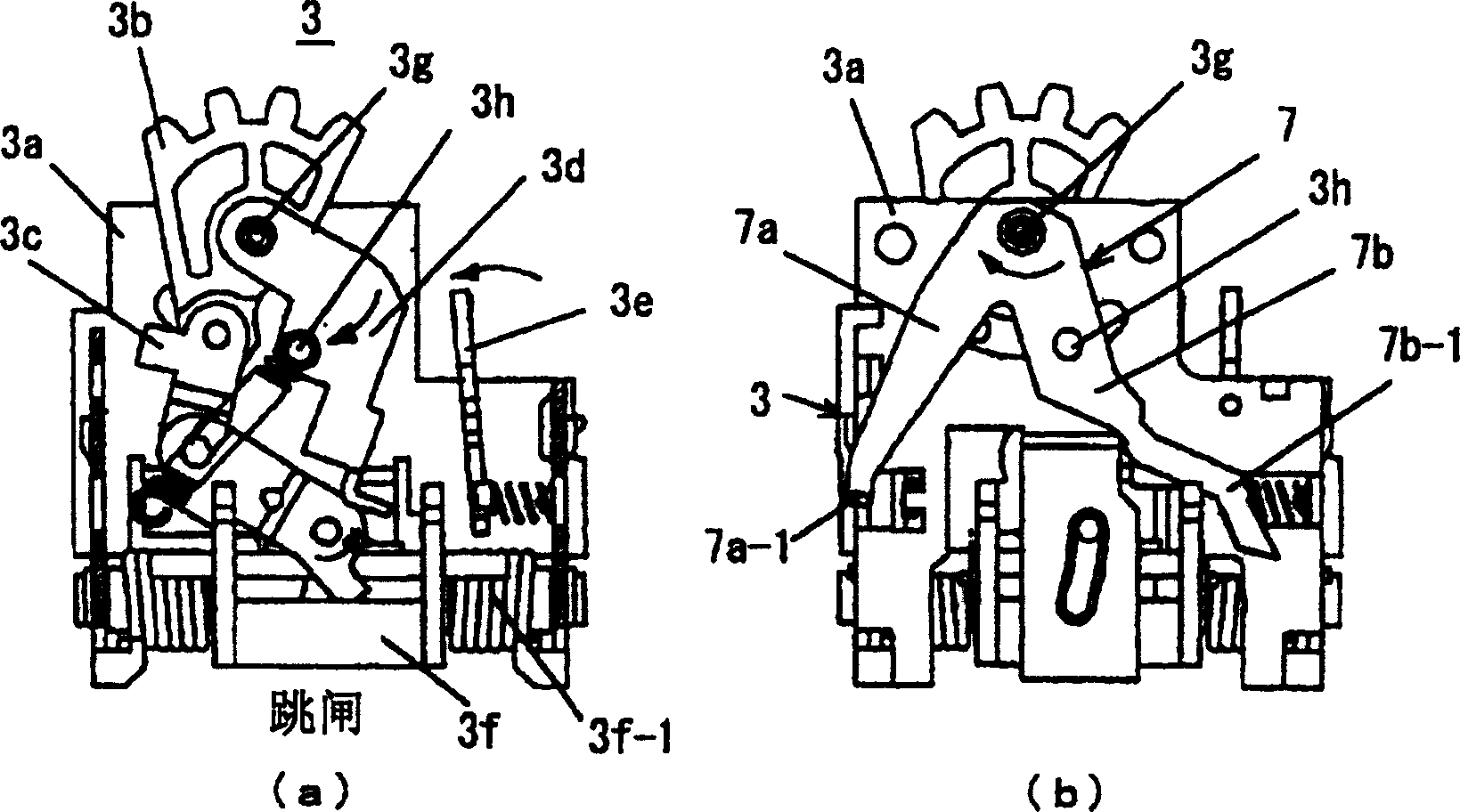

Alarm output device for circuit breaker

InactiveCN1591735AEasy to assembleStable workSwitch condition indicationProtective switch operating/release mechanismsOutput deviceEngineering

To provide an alarm output device which can flexibly cope with any of the inner and the outer attached switches attached to a circuit breaker by a sheet of plate, by improving the shape and supporting structure of an alarm output plate. The alarm output device outputs a mechanical alarm signal to an attached alarm switch interlocked with a tripping action of the circuit breaker, and makes the attached alarm switch to carry out switching action through an alarm output plate 7 assembled into an opening and closing mechanism 3. The alarm output plate 7 is formed into a shape having fork-shape leg pieces 7a, 7b extending toward the internal alarm switch 5 and the external alarm switch 6 with its tip part as a rocking fulcrum P, and operating end parts 7a-1, 7b-1 of projection shape, individually correspond to the internal and external alarm switches, are provided at the tip part of each leg piece. The rocking fulcrum is axially supported with a pivot 3g of the opening and closing mechanism, and an offset position Q offset from the fulcrum is directly insertion engaged and installed detachably with a toggle shaft of a latch which is interlocked with the releasing action of the opening and closing mechanism.

Owner:FUJI ELECTRIC FA COMPONENTS & SYST CO LTD

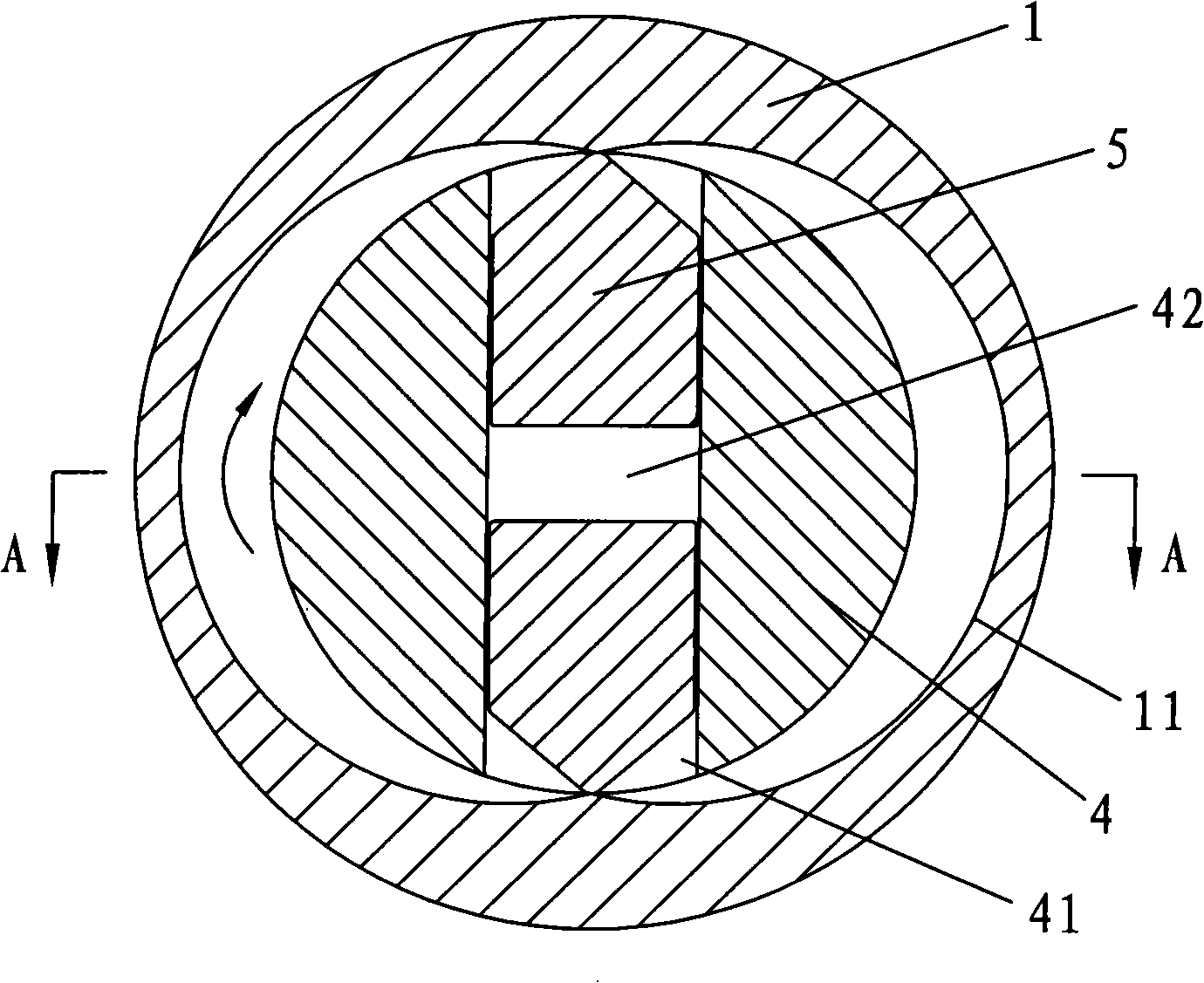

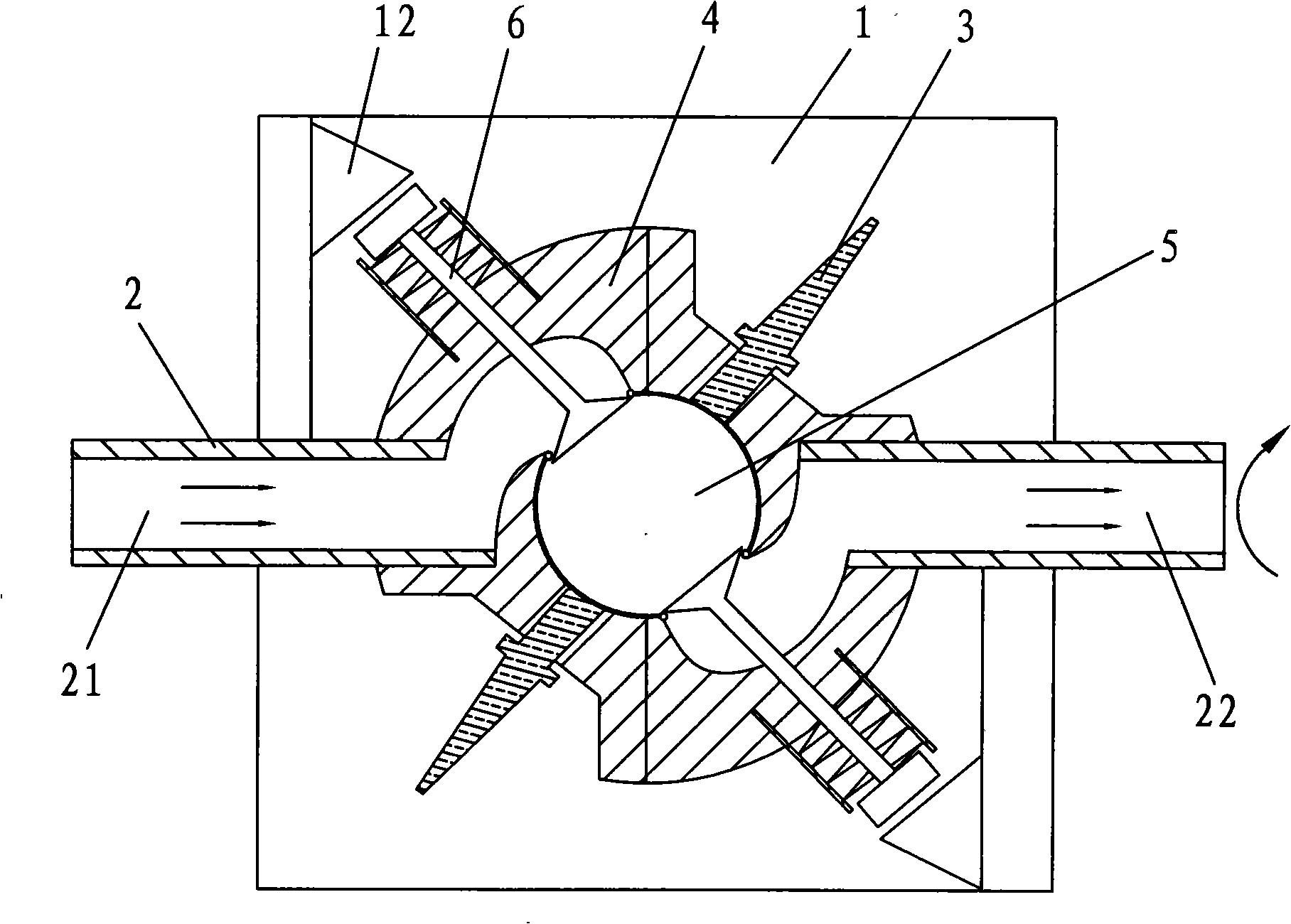

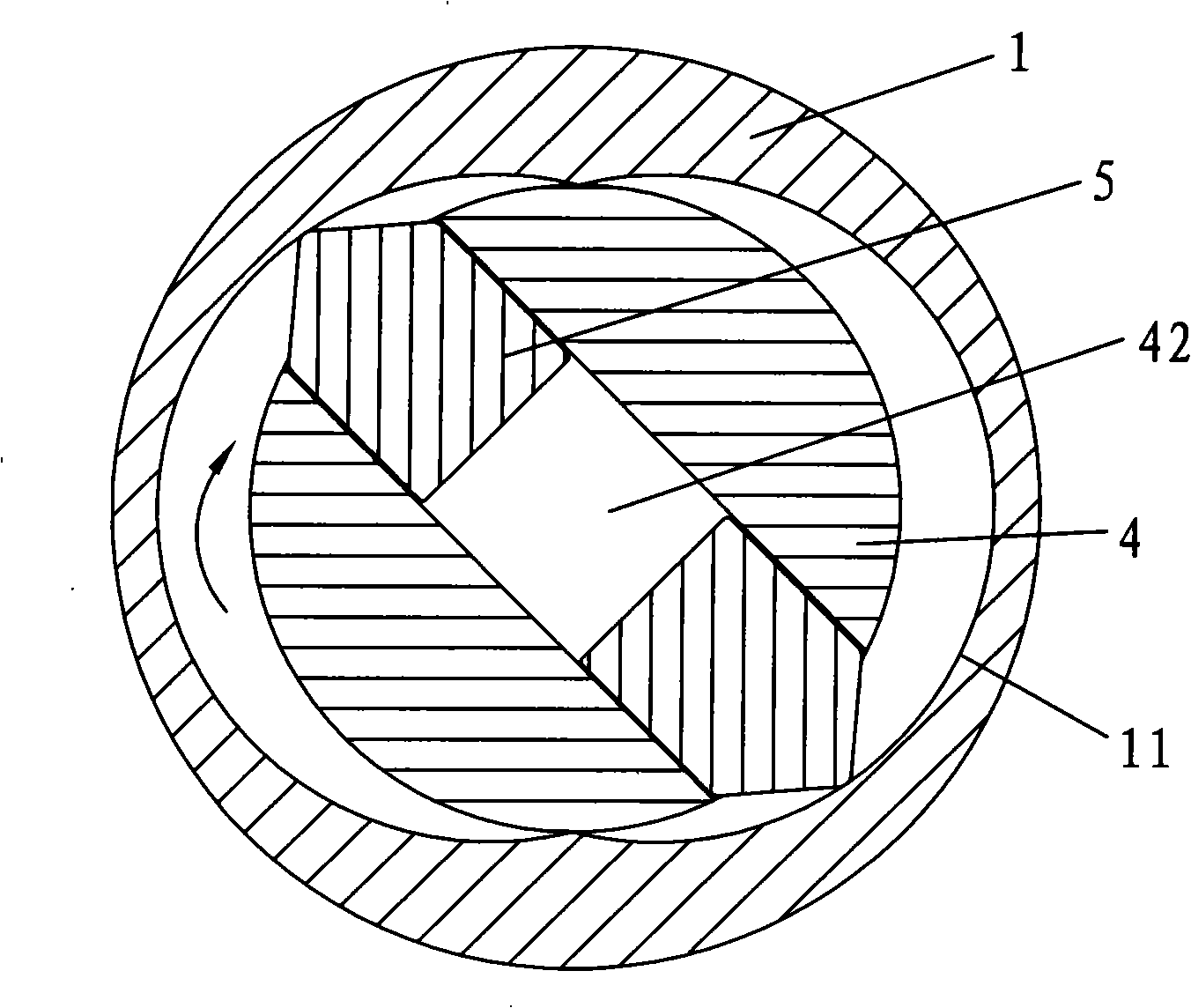

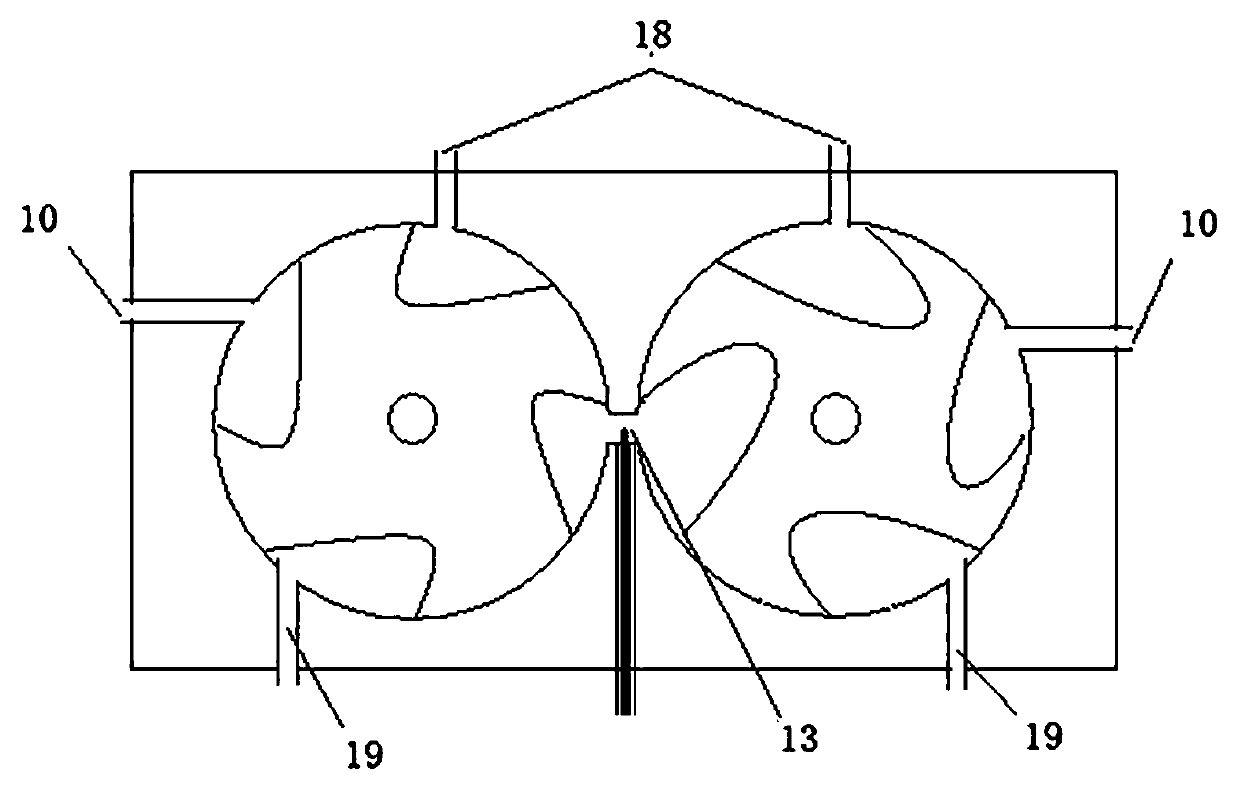

Rotary cylinder engine

InactiveCN101319632AGood mixing effectFuel burns and expands fullyInternal combustion piston enginesPistonStator

The invention relates to the technical field of engines, in particular to a rotating cylinder engine; the rotating cylinder engine comprises a stator, a rotating shaft which rotates in the inner cavity of the stator and a spark plug; both sides in the stator are provided with eccentric arc-shaped walls; a rotating cylinder is arranged in the stator; the rotating cylinder is coaxially fixed at the medium part of the rotating shaft; the rotating cylinder is provided with a radially through cylinder; two pistons are connected with the inside of the cylinder in a sliding way; a burning chamber is formed between the two pistons and the cylinder; the rotating shaft is a hollow shaft, and the inner cavity of the rotating shaft is communicated with the burning chamber on the rotating cylinder; the spark plug extending into the burning chamber is inserted on the rotating cylinder; the rotating cylinder completes a working circulation process and makes power for once after rotating for a round; the fuel and air mixing effect is good, the fuel is burned and expanded fully, the output torque is small, the noise is low, the operation is stable and the structure is simple.

Owner:翟树球

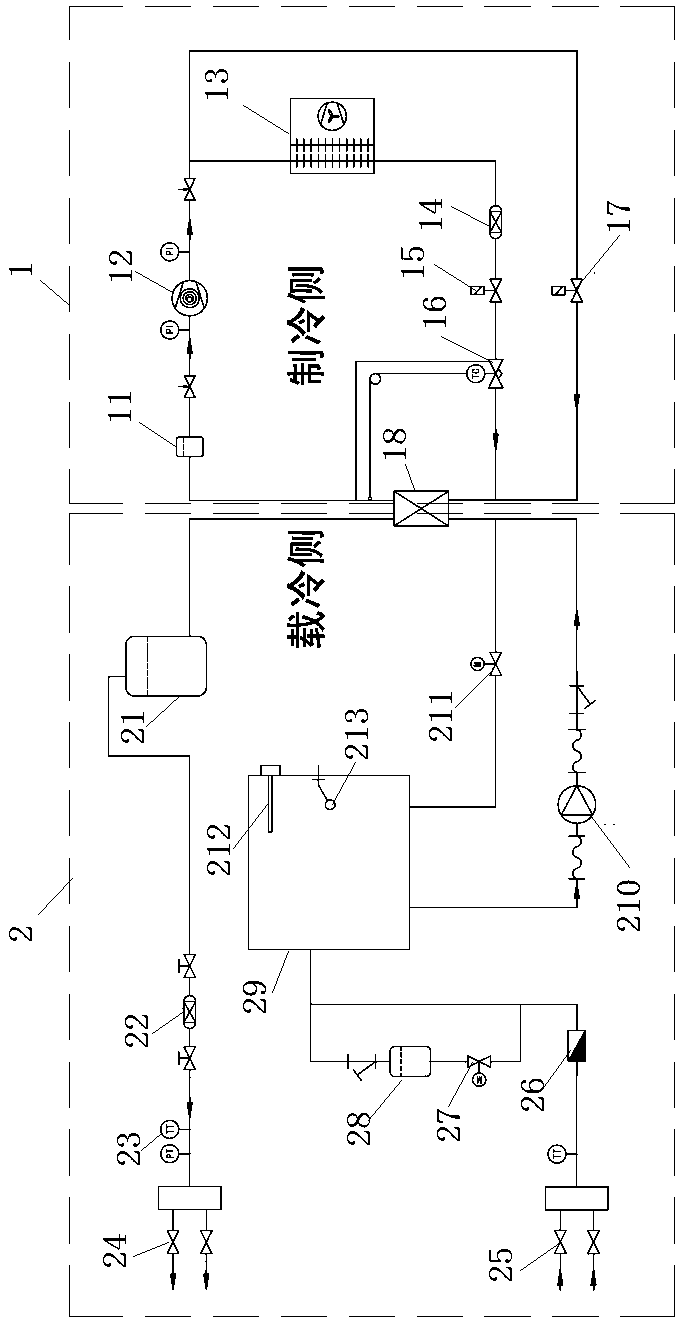

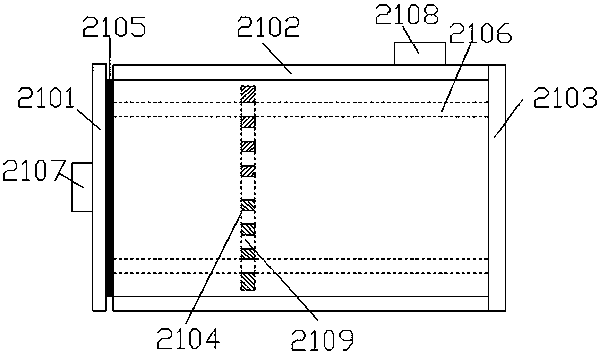

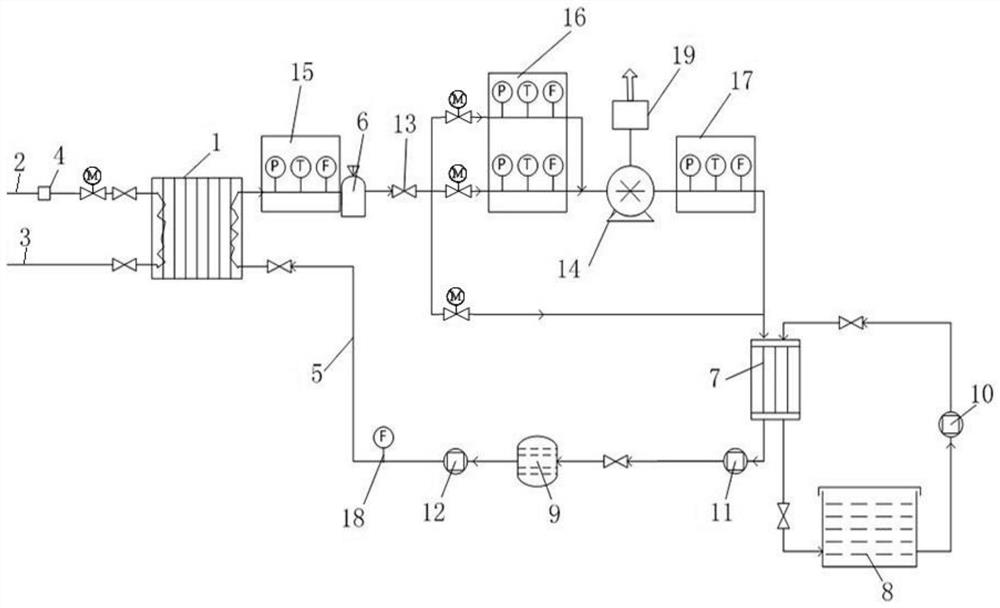

A laser circulation cooling system and its control method

ActiveCN104953445BStable jobStable workCompression machines with non-reversible cycleSemiconductor lasersRefrigeration compressorSolenoid valve

The invention relates to a laser circulation cooling system and a control method thereof. The cooling system includes a cooling side system, a load cooling side system and a main control system. The cooling side system includes gas-liquid separator, compressor, condenser fan assembly, filter, first solenoid valve, expansion valve, second solenoid valve and plate heat exchanger. The load-cooling side system includes a buffer water tank for uniformly mixing fluids with temperature differences, a high-efficiency filter, a first regulating valve, a second regulating valve, a flow sensor, a first proportional valve, an ion adsorber, a closed water tank, a water pump and a second Two proportional valves. A temperature sensor is arranged on the pipeline between the high-efficiency filter and the first regulating valve. A conductivity detection device and a liquid level switch are arranged in the airtight water tank. The invention can not only meet the flow and pressure requirements of sensitive devices inside the laser, but also can precisely control the temperature of the fluid to ensure the stable operation of the refrigeration compressor.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

Polyethylene film intelligent winding machine and polyethylene film production method

The invention discloses a polyethylene film intelligent winding machine and a polyethylene film production method. The polyethylene film intelligent winding machine comprises a bottom plate, wherein the upper end face of the bottom plate is connected with side plates through supporting legs, the side plates are made of stainless steel of a quasi-rectangular structure, the surface of each side plate is provided with a feeding motor, one end face of each feeding motor is in transmission connection with a feeding shaft, the portion, located below the front portion of the corresponding feeding motor, of the surface of each side plate is provided with a pressing motor, and a pressing roller is installed between the two pressing motors through bearings. According to the polyethylene film intelligent winding machine, by arranging deviation correcting devices, the position of film is monitored in real time, the problem that an existing device cannot sensitively sense the deviation of the film is solved, the coping capacity of the device to the deviation of the film is improved, and a stable deviation correcting effect is achieved; and by arranging rotating rings, a foundation is laid for overall matching work of the device, and the use experience is improved.

Owner:上海佰鑫新材料科技有限公司

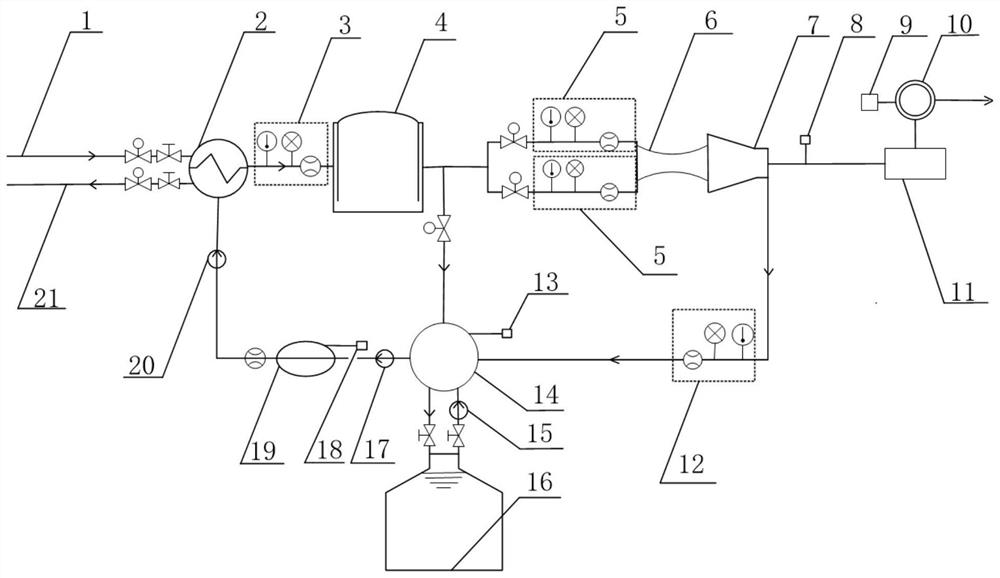

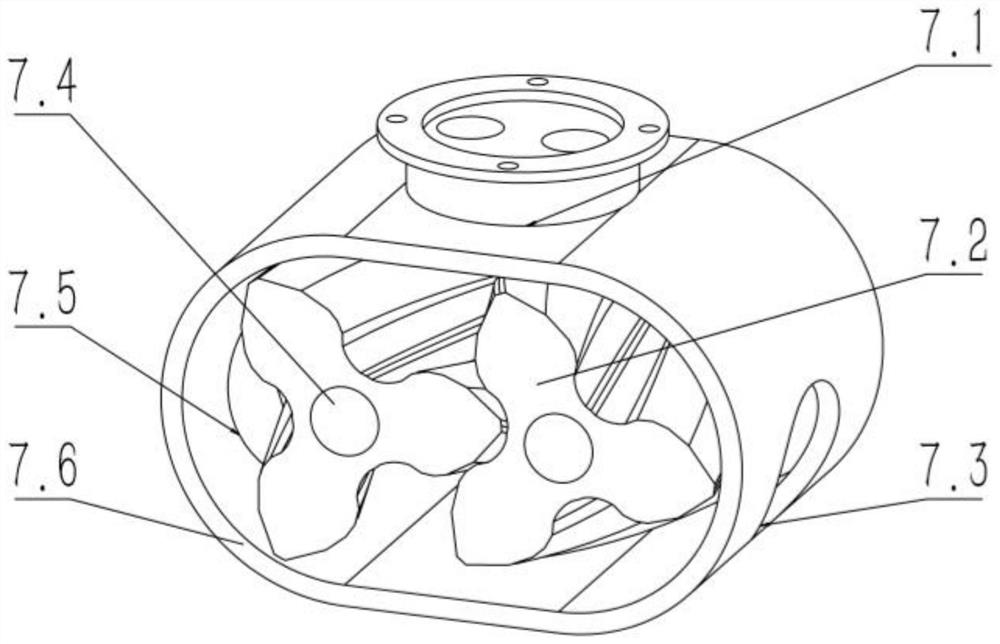

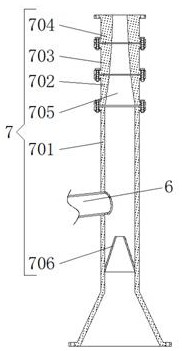

A low-quality waste heat recovery and utilization system

ActiveCN111749742BIncrease profitHigh heat conversion efficiencyLiquid degasificationFeed water supplyProcess engineeringGas holder

The invention discloses a low-quality waste heat recovery and utilization system, which includes a waste heat recovery system and a circulation system; the waste heat recovery system includes a waste heat inlet pipeline, a heat pipe steam generator and a waste heat outlet pipeline; the circulation system includes a gas storage tank sensor group, a storage tank Air tank, air inlet sensor group, Laval nozzle, Roots power machine, air outlet sensor group, condenser liquid level gauge, condenser, condensate make-up pump, make-up liquid tank and feed liquid pump. This system uses low-quality waste heat gas as the heat source. The waste heat recovery system makes the liquid working fluid absorb the heat in the waste heat gas and convert it into a gaseous state. The vapor is condensed into a liquid state through the condenser, and continues to be recycled. This system realizes the high-efficiency recovery and reuse of low-quality waste heat, with simple structure, high energy utilization rate and high heat conversion efficiency.

Owner:江苏科瑞德智控自动化科技有限公司 +1

Energy-saving temperature control device for mountain area service area based on terrestrial heat absorption

InactiveCN113565712AGuaranteed water supplyGuaranteed temperature environmentGeothermal energy generationHollow article cleaningWater useEngineering

The invention discloses an energy-saving temperature control device for a mountain area service area based on terrestrial heat absorption. The energy-saving temperature control device comprises a terrestrial heat water tank, a steam turbine module, a power grid module, a backflow tank, a liquid level sensor, a service area water using module and an electric heating element, wherein a heat collection water tank is connected to the outer side of the terrestrial heat water tank, the steam turbine module is arranged on the outer side of the terrestrial heat water tank, a generator module is installed on the outer side of the steam turbine module, the backflow tank is arranged on the outer side of the heat collection water tank, a high-temperature water tank is connected to the tail end of a third inflow pipe, and a feeding hole is formed in the top of the heat collection water tank. For the energy-saving temperature control device for a mountain area service area based on terrestrial heat absorption, energy development and utilization are carried out based on terrestrial heat energy, water supply of various levels of temperatures can be guaranteed for the mountain area service area, water use inside and even outside the mountain area service area can be guaranteed conveniently, cyclic operation can be achieved at the same time, energy waste is reduced, energy saving and temperature control are facilitated, and the temperature environment of the service area is ensured.

Owner:王嘉川

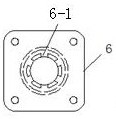

Distribution system

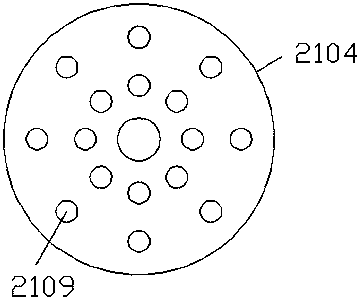

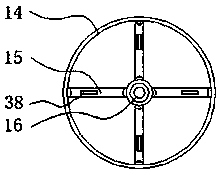

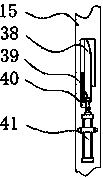

InactiveCN106111385ASolve the situation of uneven deliveryGuaranteed uniformityLiquid spraying apparatusDrive shaftDistribution system

The invention discloses a distribution system. A transmission shaft is arranged in a box body. One end of the transmission shaft penetrates the box body to be arranged outside the box body. The transmission shaft is connected with a transmission connector. A centrifugal flyweight is arranged on the transmission shaft in a sleeving and combined manner. A distribution pump is connected to the end, away from the transmission connector, of the transmission shaft and connected with an oil conveying pump in a communicating manner. The oil conveying pump is arranged inside the box body. Oil atomizers are arranged outside the box body. An oil amount control valve is arranged above the distribution pump. The oil conveying pump is connected with a pressure regulating valve. The pressure regulating valve is arranged inside the box body and communicates with the oil conveying pump. An upper pressure regulating spring, a lower pressure regulating spring and a slide column are arranged in the pressure regulating valve. The slide column is arranged between the upper pressure regulating spring and the lower pressure regulating spring. The pressure regulating valve communicates with a filter through a pipeline, wherein the filter is arranged outside the box body. By means of the system, the uniformity of pump conveying pressure can be ensured so that the system can stably do work; and even during running of multiple sets of parallel systems, unification of the running state can also be achieved, and the product quality is ensured.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

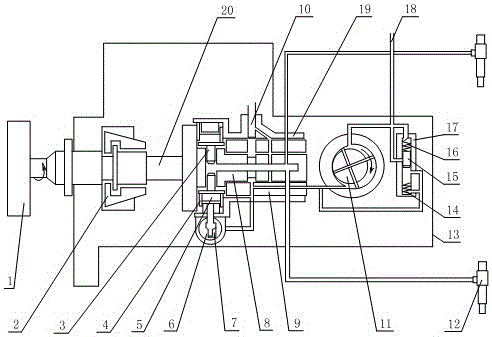

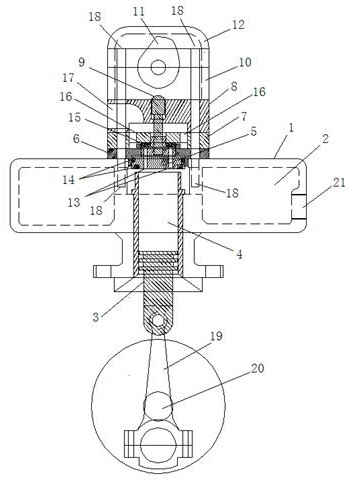

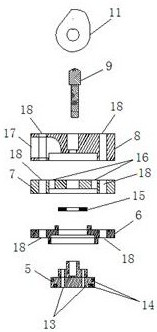

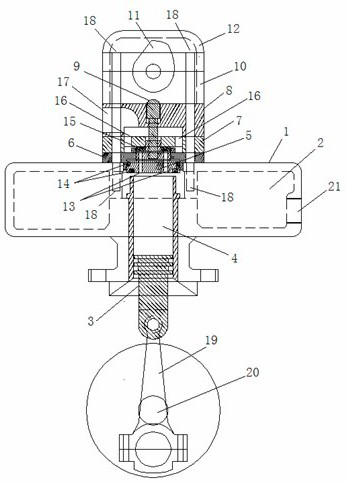

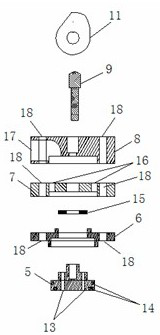

Air engine and air engine system moving like breathing air

The invention provides an air engine and an air engine system moving like breathing air. The air engine comprises an air engine body, a piston, a movable air valve, a movable air valve cover, an exhaust valve plate, an exhaust cover, an air valve jacking rod, a cam shaft seat, a cam shaft with a cam, a cam shaft cover, a connecting rod, a crankshaft and the like. The invention further provides theair engine system moving like breathing the air. The air engine applies work stably and has the advantages of being simple in structure, low in manufacturing cost, low in energy consumption, environmentally friendly and the like.

Owner:张谭伟

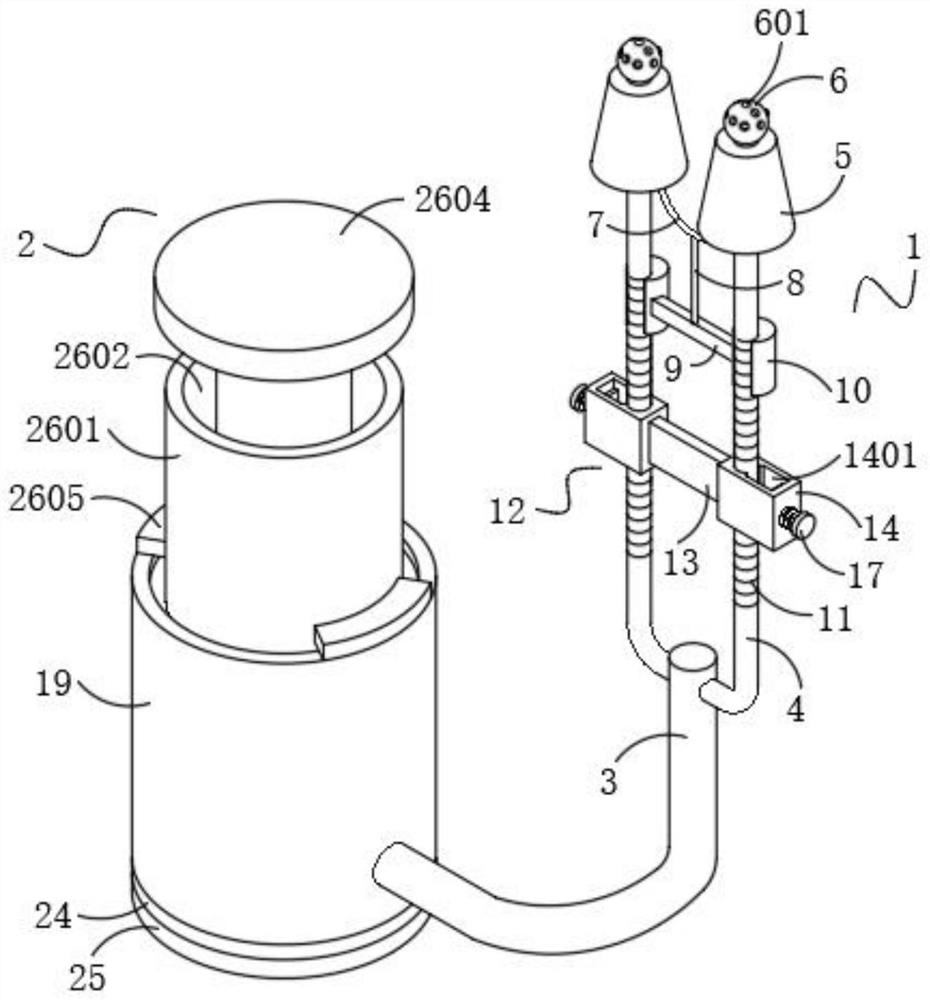

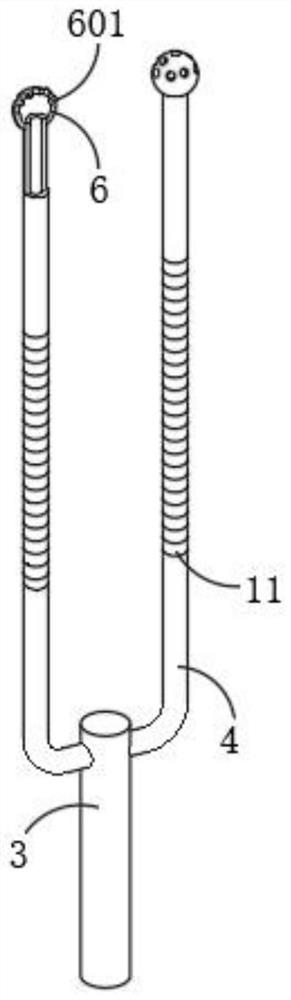

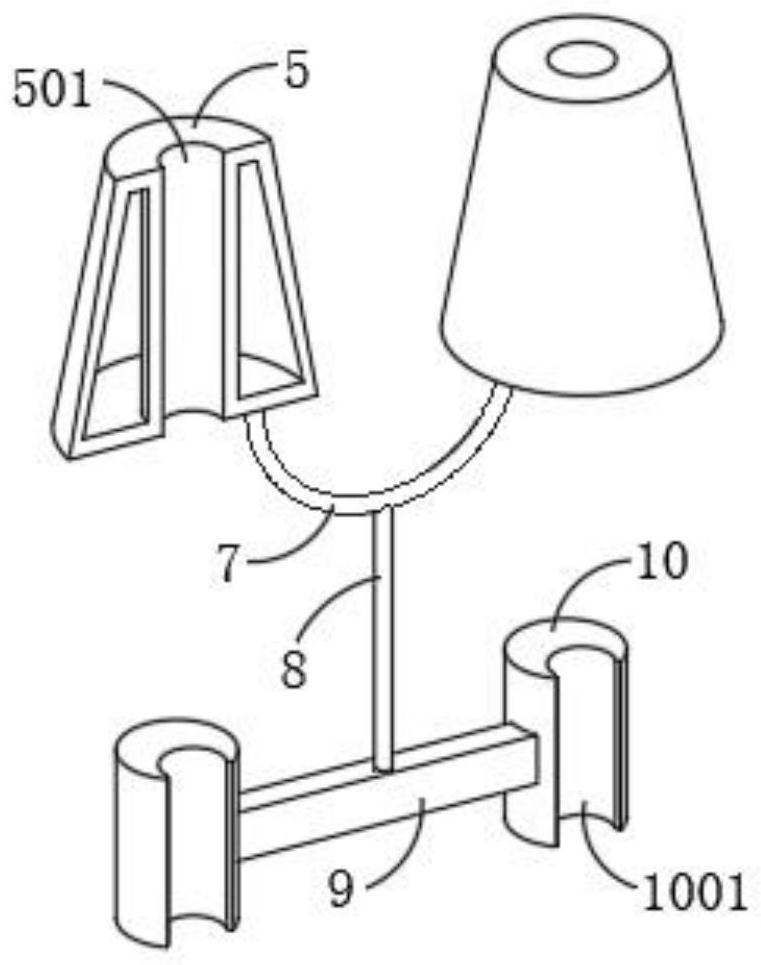

Nasal cavity medicine applying device for otolaryngology department

InactiveCN114652950AFlexible adjustment of expansion and contractionIncrease flexibilityMedical devicesNoseNasal Cavity Epithelium

The nasal cavity medicine applying device for the otolaryngology department comprises a conveying and guiding structure used for injecting liquid medicine into the nasal cavity, the conveying and guiding structure comprises an infusion tube, a medicine injection structure used for supplying the liquid medicine is arranged at one end of the infusion tube, and the other end of the infusion tube is communicated with two symmetrically-arranged infusion branch tubes in a guiding mode; a hollow liquid spraying protruding ball is arranged at the outlet end of each liquid conveying branch pipe, and spraying holes are formed in a ball body of each liquid spraying protruding ball. The infusion tube with the two infusion branch tubes is designed, the two infusion branch tubes are sleeved with the nose plugs in a sliding mode, the two nose plugs are used in a combined mode, and the two nose plugs are provided with the two clamping bases capable of flexibly adjusting the stretching amount of the two infusion branch tubes. Therefore, the two infusion branch pipes can be flexibly controlled to go deep into different areas of the nasal cavity for administration treatment. And the medicine seat in which the injection needle tube combination can be flexibly inserted is adopted and is matched with the infusion tube to accurately and efficiently supply liquid medicine, so that the nasal cavity is conveniently subjected to medicine application treatment, and the use convenience is improved.

Owner:广西医科大学第二附属医院

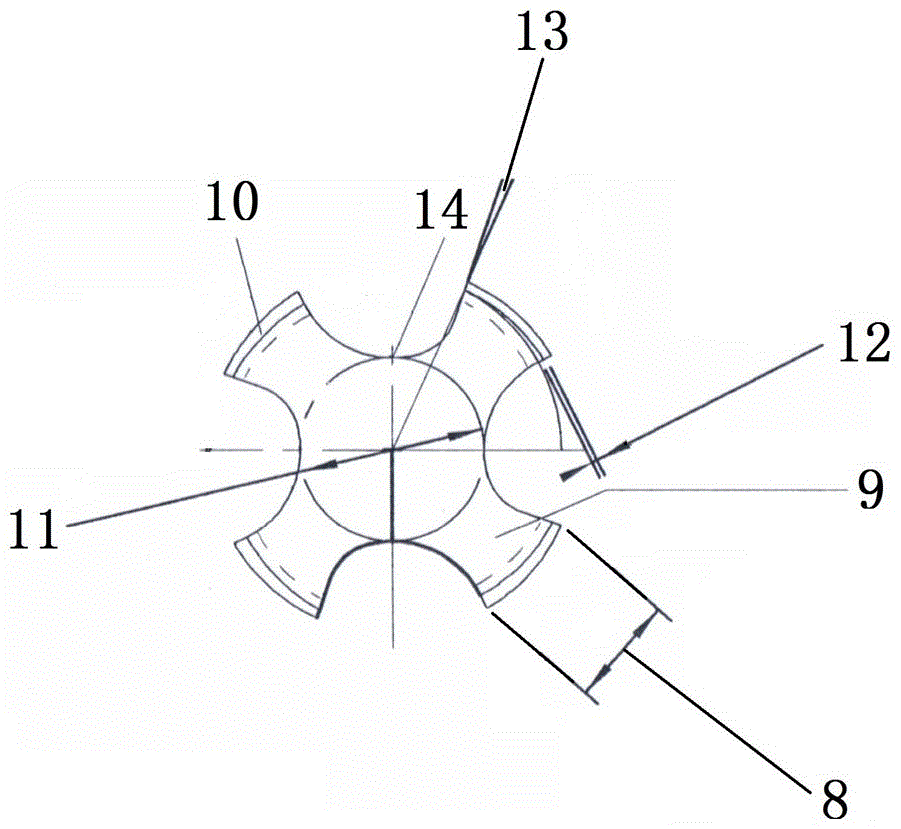

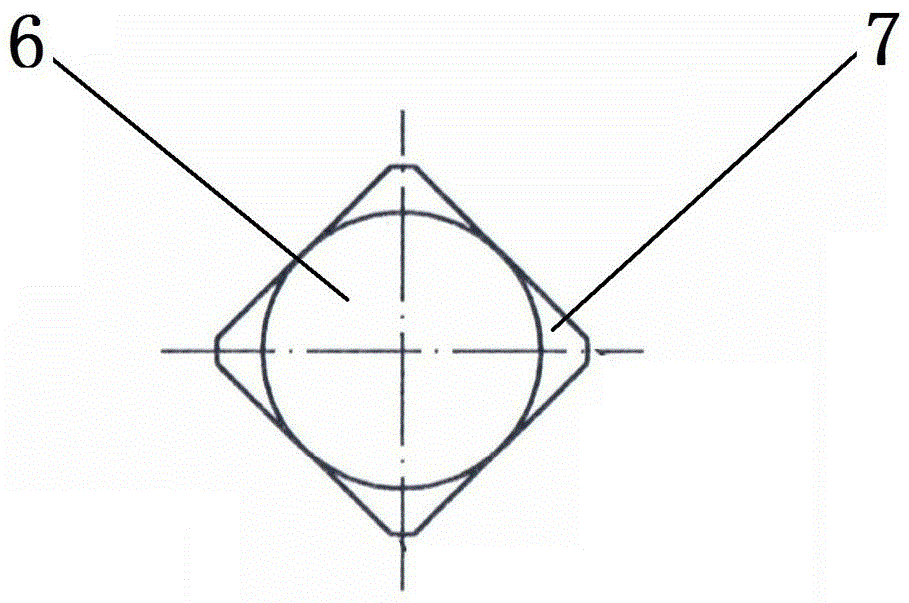

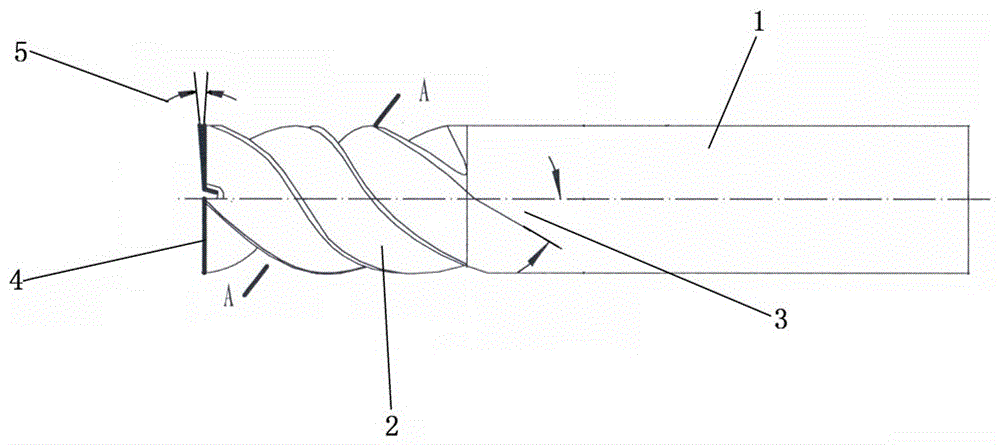

Screw tap

The invention discloses a screw tap, which comprises a metal cutting part and a metal shank connected integrally with each other. The screw tap is in a cylindrical shape and placed transversely, and the total length of the left and right of the screw tap is 115mm. Four straight flutes are excavated from the left to the right on the cylindrical surface of the screw tap, and are evenly distributed on the cylindrical surface of the screw tap and correspondingly form four cutting-belts. The right end of each of the four straight flutes is a circular arc shape. Four cutting-belts are respectively provided with cutting-teeth by grinding, and a cutting-slot is formed between two adjacent cutting-teeth. A left pyramid is formed by grinding from the right to the left on the outer circumference of metal cutting part and in the distance of 13 mm from a left end face of the screw tap. A circle chamfering is formed by grinding from left to right to form a right pyramid on the outer circumference of metal cutting part and in the distance of 37mm from a left end face of the screw tap. A right end face of the right pyramid is connected with the metal shank. The right end of the metal shank is turned into a square head, and the four right angles of the right end face of the square head are turned into arc angle. The outer ring of the left end face of each of the four cutting-belts is provided with a blade by grinding.

Owner:PINGHU CITY SHANTE THREAD TOOL

Waste recovery and reuse device with dust-proof structure

The invention discloses a waste recovery and reuse device with a dust-proof structure, and relates to the technical field of recovery and reuse devices. The waste recovery and reuse device with the dust-proof structure comprises a sewage pool, a water storage drum and a feeding inlet; a sewage pipe is mounted on the upper part of the sewage pool, a storage chamber is formed in the front end of thesewage pipe, and pressing blocks are mounted on the left and right sides of the storage chamber; and pushing rods are mounted in the middles of the pressing blocks, a water pump is mounted at the front end of the water storage drum, the water storage drum is located on the left side of the storage chamber, and a soft water pipe is connected to the upper part of the water storage drum. According to the waste recovery and reuse device with the dust-proof structure, through cooperation of a hoisting drum, an overturning plate and a locking pin, a movable storage space is provided for waste, whenthe hoisting drum moves to the upper part of the feeding inlet, the overturning plate can rotate along the exterior of the lock pin through cooperation between a third hydraulic column and a steel rope, and the waste in the hoisting drum can be effectively placed into the feeding inlet.

Owner:段亚斌

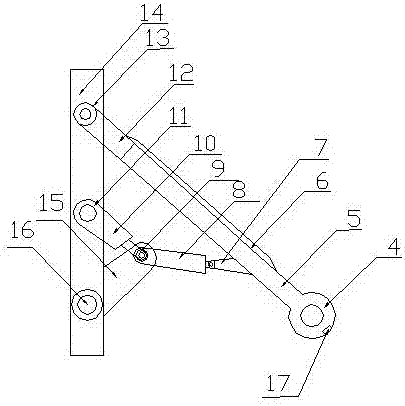

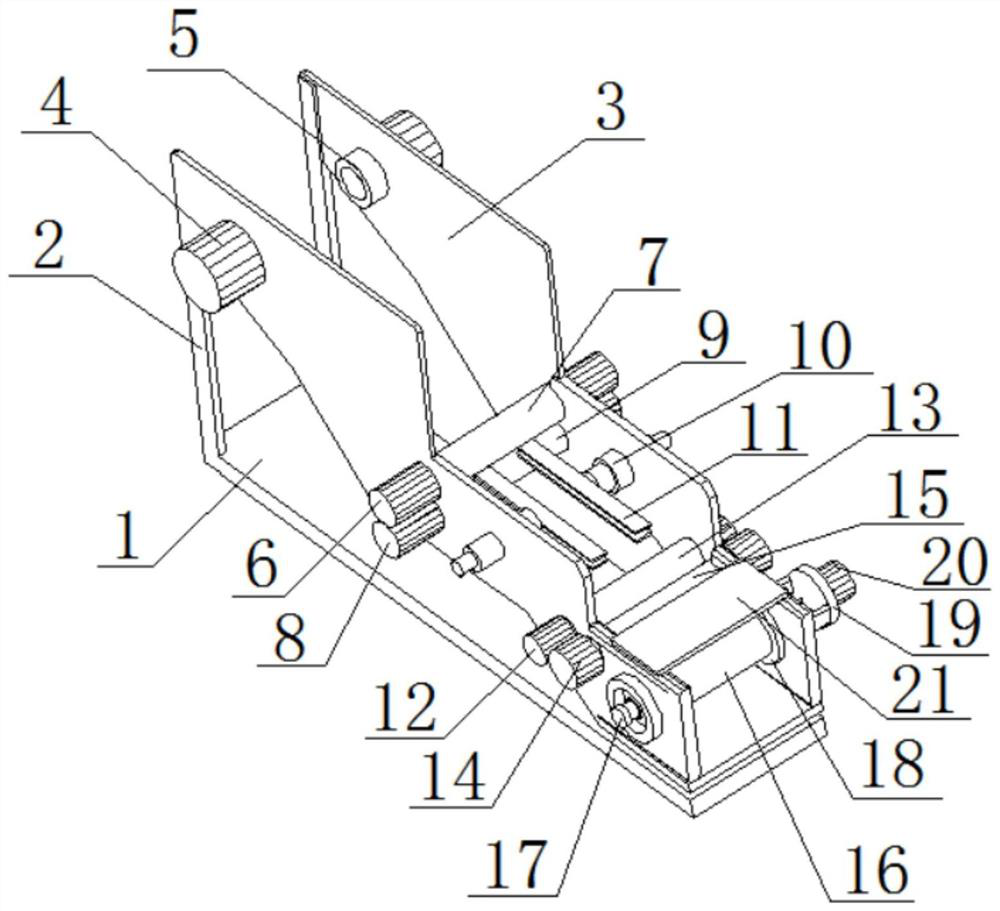

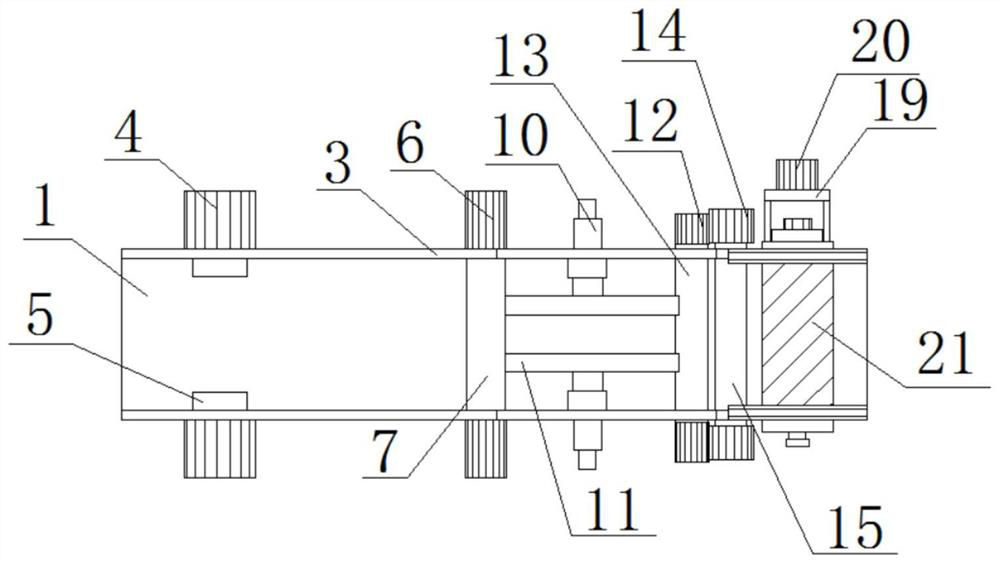

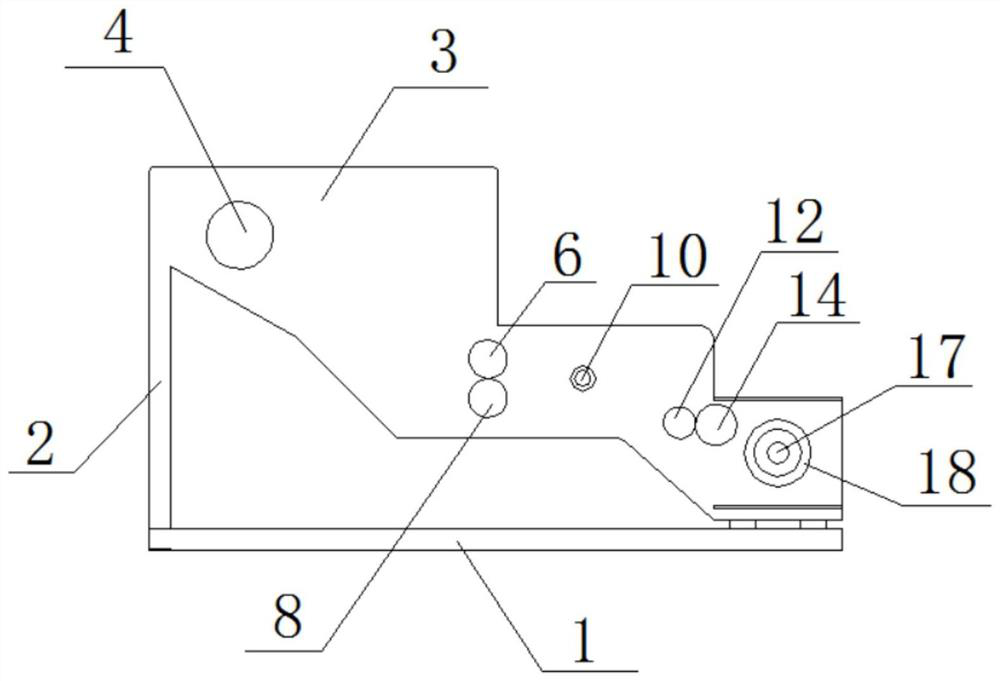

Belt detachment tool for pumping unit in oil field

InactiveCN105150162AAchieve installationAchieve disassemblyMetal-working hand toolsHydraulic cylinderThrust bearing

The invention discloses a belt detachment tool for a pumping unit in an oil field, and belongs to the field of petroleum machinery. The belt detachment tool comprises a driving device, a fixing device, a belt carrying device and an adjustment device. The driving device comprises a rotary hydraulic cylinder, an outer spline shaft and an inner spline shaft. The fixing device comprises an inner movable sheet bar and a clamping ring. The belt carrying device comprises an outer movable sheet bar and a static sheet bar. The adjustment device comprises a bearing platform, a thrust bearing, a screw nut, a lead screw, a bearing seat, a second bearing and a bearing cover. The movable sheet bars and the static sheet bar can break away and get close to realize the installation and detachment of a belt. The belt detachment tool can be installed on a belt wheel only through one bolt, so that operation is simple. A motor does not need to move in the detachment and installation process of the belt, it is guaranteed that the pre-tightening force of the belt is basically constant, the motor works stably, an operator only needs to drive a manual hydraulic pump and does not need to take part in other processes, safety risks are reduced, and operation efficiency is improved.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

A quick replacement device for motor belt of pumping unit in oil field

The invention discloses a motor belt rapid replacement device for a pumping unit in an oil field, and belongs to the field of petroleum machinery. The motor belt rapid replacement device comprises a driving device, a fixing device and an adjustment device. The driving device comprises a positioning shaft, a spline shaft and a first bearing. The fixing device comprises a non-standard spline sliding rail pair inner ring and a belt wheel shaft clamp. The adjustment device comprises a non-standard spline sliding rail pair outer ring, a second bearing, a lead screw, two lead screw seats, a screw nut, a revolving shaft seat, a third bearing and an outer ring bearing chamber. The non-standard spline sliding rail pair outer ring axially slides on the non-standard spline sliding rail pair inner ring so that a belt can break away from a belt wheel, and installation and detachment of the belt can be realized. The motor belt rapid replacement device can be installed on the belt wheel only through one bolt, so that operation is simple. A motor does not need to move when the belt is detached and installed, and contact between the hands and the belt can be completely avoided. By properly tensioning the belt, the replacement motion of the belt is finally realized without damaging the belt, safety risks are reduced, and operation efficiency is improved.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

A high-efficiency utilization system of low-quality waste heat

ActiveCN111535889BIncrease profitEnable recyclingCombination devicesEngine of intermeshing engagement typeLiquid storage tankCondensate pump

The invention discloses a system for high-efficiency utilization of low-quality waste heat. The system for the high-efficiency utilization of the low-quality waste heat comprises a waste heat recoverysystem and a circulating system, wherein the waste heat recovery system comprises an evaporator, a waste heat inlet pipe, a waste heat outlet pipe and a filtering device; and the circulating system comprises an organic working medium pipeline, a gas storage tank, a condenser, a liquid storage tank, a condensate pump, a liquid replenishing pump, flow dividing control valves, a Roots power machine,a gas storage tank sensor group, a gas inlet sensor group, a gas outlet sensor group and liquid replenishing flowmeters. According to the system for the high-efficiency utilization of the low-qualitywaste heat, low-quality waste heat gas is used as a heat source, an organic working medium is used as a circulating working medium, the waste heat recovery system enables the liquid organic working medium to absorb heat from the waste heat gas and convert the heat into a gaseous state, the steam of the organic working medium enters the Roots power machine to push the Roots power machine to do work, heat energy is converted into mechanical energy, and then the steam of the organic working medium is condensed into the liquid state through the condenser and is continuously recycled. The system for the high-efficiency utilization of the low-quality waste heat achieves recycling of the low-quality waste heat, and is simple in structure, high in energy utilization rate and high in heat conversion efficiency.

Owner:江苏科瑞德智控自动化科技有限公司 +1

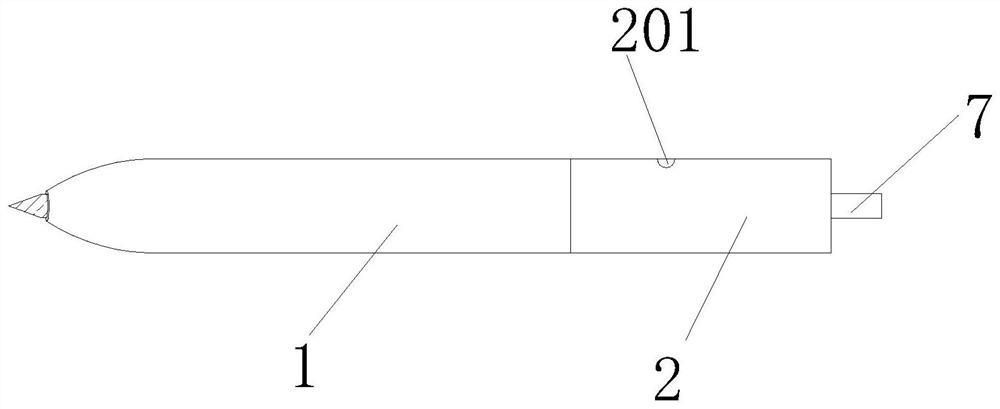

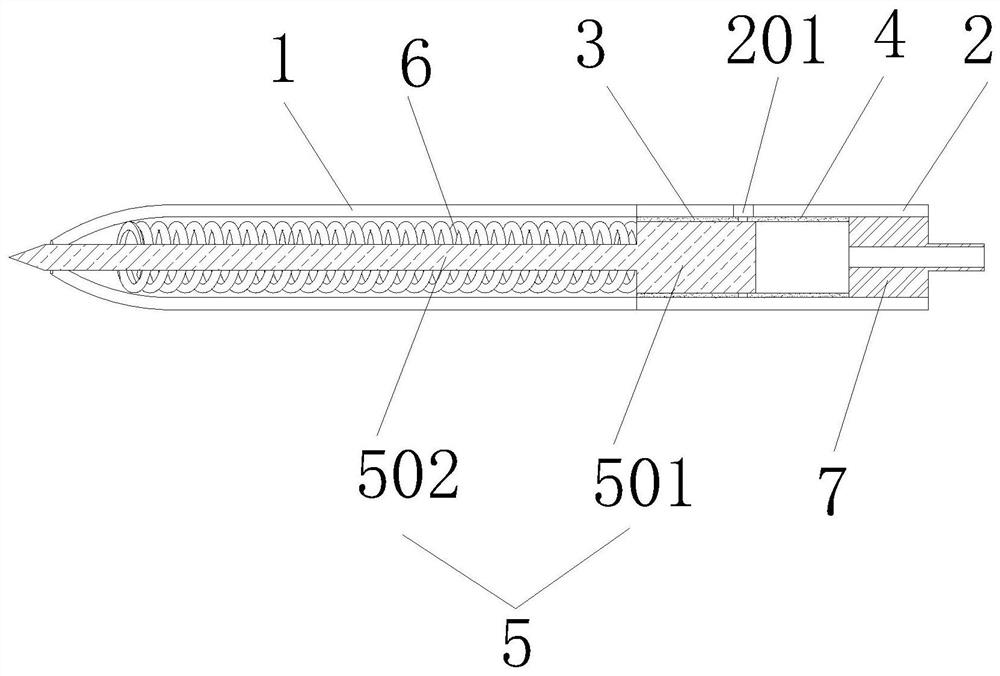

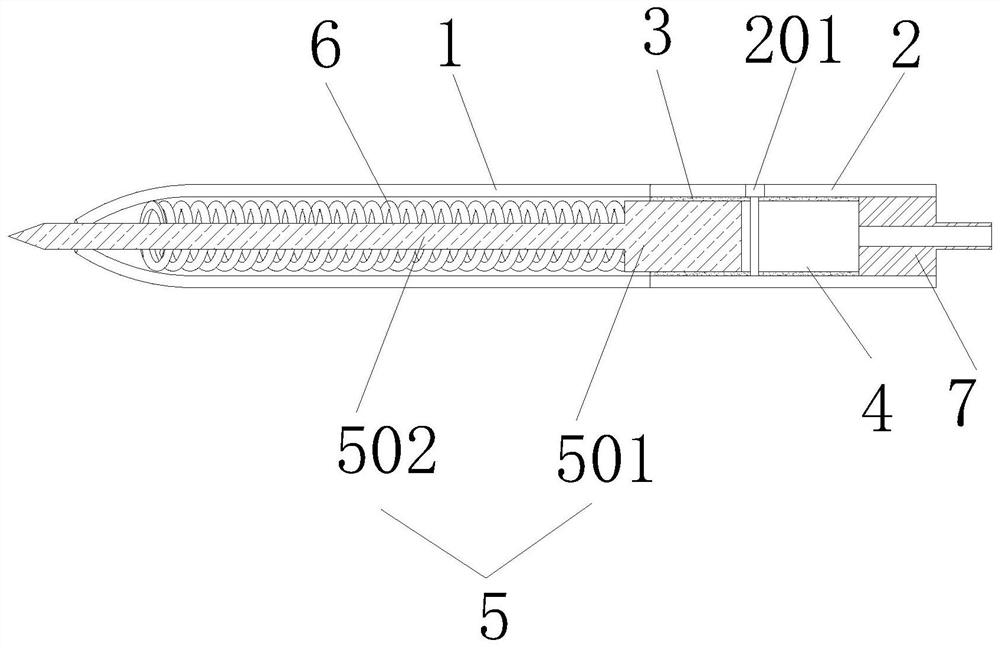

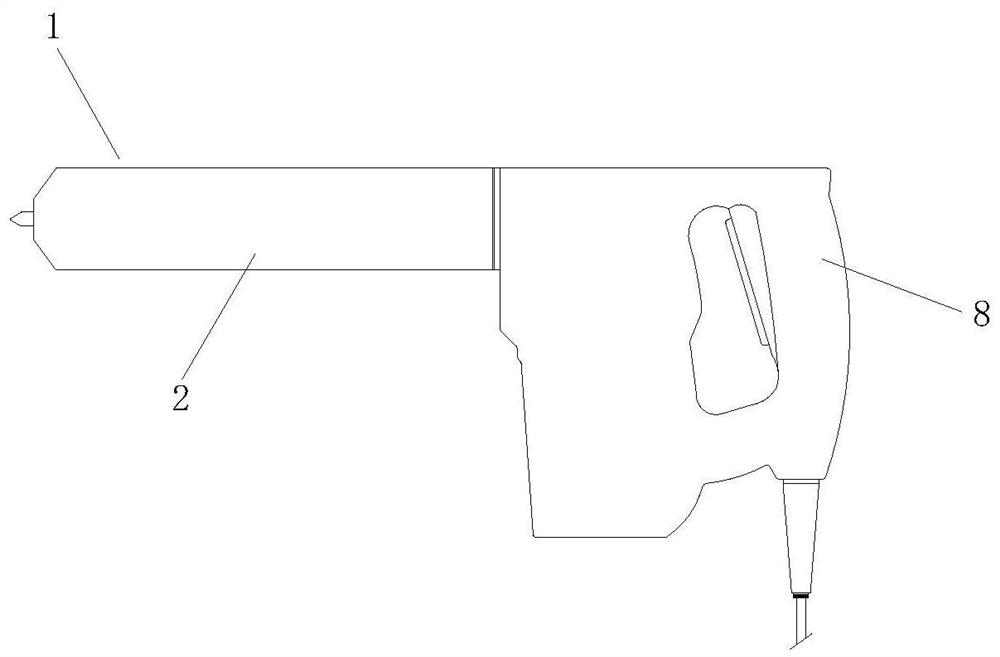

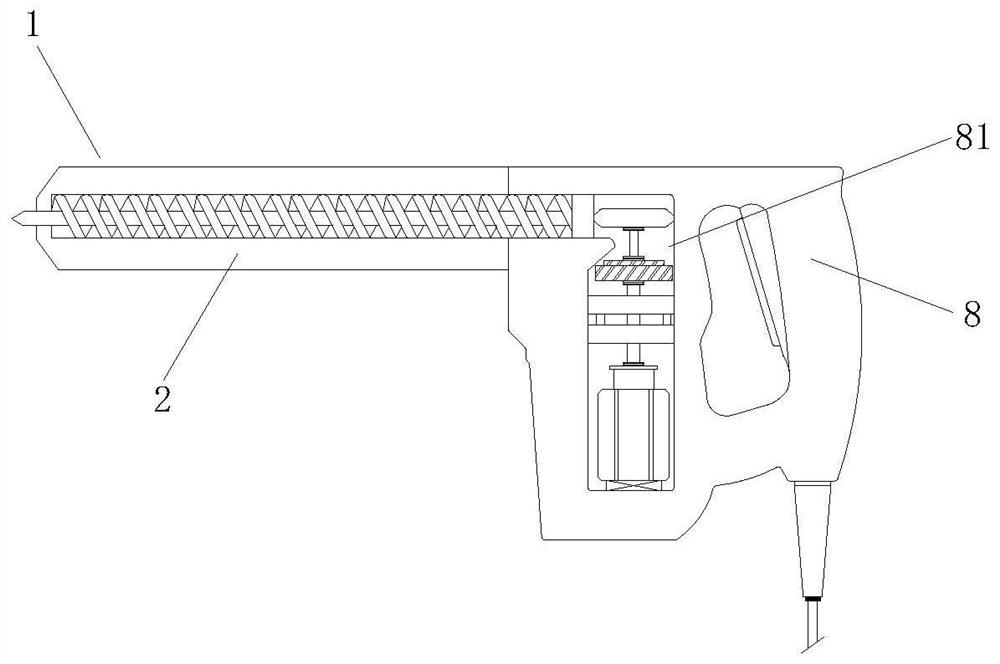

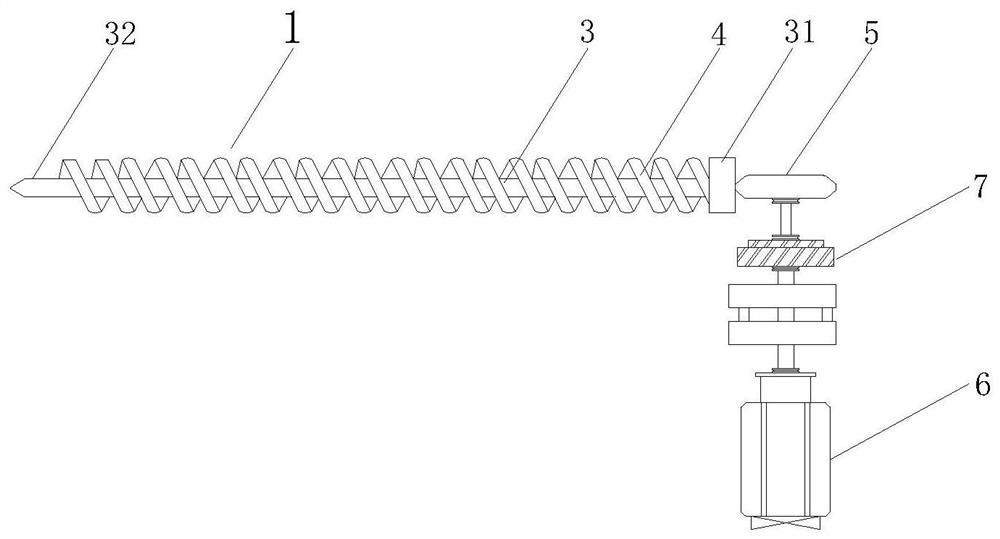

Air cylinder type pneumatic pen

PendingCN113798278AEasy to clean under the shakePrevent agingCleaning processes and apparatusRubber ringEngineering

The invention relates to the technical field of archaeological tools, in particular to an air cylinder type pneumatic pen which comprises a pen body. A lining connecting cylinder is installed on the right side of the pen body, a first tungsten steel air closing sleeve is installed in the lining connecting cylinder and located on the left side of an air hole, and a second tungsten steel air closing sleeve is installed in the lining connecting cylinder and located on the right side of the air hole. A piston rod is arranged in the pen body, an air pipe connector is installed on the right side of the lining connecting cylinder in an embedded mode, the whole device facilitates vibration-down cleaning of gravels and tiny attachments on fossils, meanwhile, stable acting is guaranteed through rear exhaust, and a piston movement air closing structure is arranged, so that the aging phenomenon caused by air closing of a rubber ring is avoided, stability and practicability are high, and certain popularization value is achieved.

Owner:隆之古文化科技(苏州)有限公司

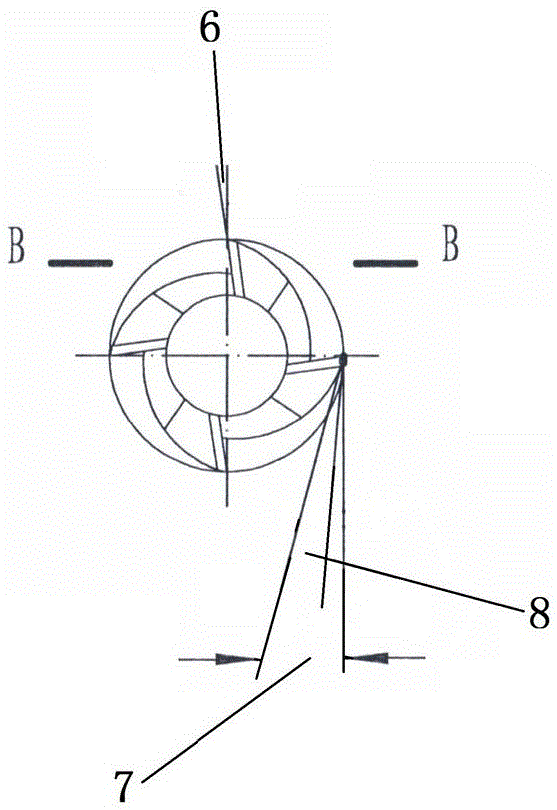

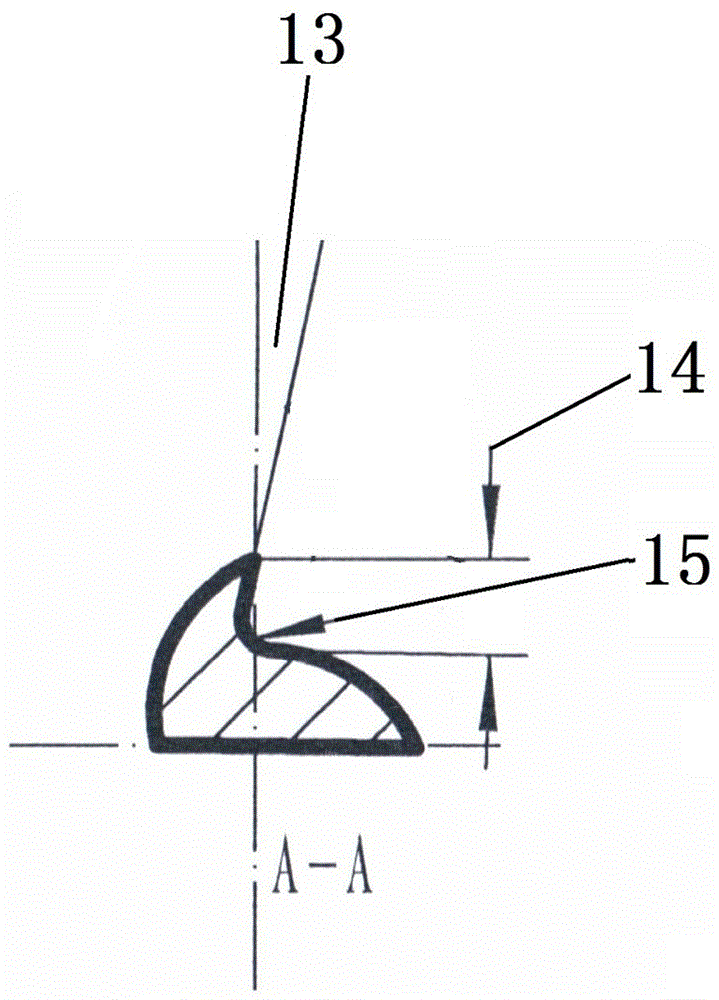

Computer numerical control (CNC) milling cutter with four teeth

InactiveCN106475617AMeet production standardsCorrectly designedMilling cuttersNumerical controlMilling cutter

The invention discloses a computer numerical control (CNC) milling cutter with four teeth. The CNC milling cutter comprises a metal handle and a cutter part, wherein the metal handle takes the shape of a cylinder, is placed horizontally, and is positioned on the right side of the CNC milling cutter; the cutter part of the CNC milling cutter is machined from a metal cylinder, placed horizontally, positioned on the left side of the CNC milling cutter, and conjoined with the metal handle of the CNC milling cutter; four end tooth bodies of the four teeth of the CNC milling cutter are uniformly distributed on the left end surface of the CNC milling cutter; an included angle I is formed between the cutting edge line of each end tooth body and the middle perpendicular line of the left end surface; each end tooth body comprises a front angle I, a first rear angle I and a second rear angle I; the tooth top part of each end tooth body protrudes from the left end surface of the CNC milling cutter, and an included angle II is formed between the tooth top part of the end tooth body and the left end surface of the CNC milling cutter; four circumferential tooth bodies of the four teeth are spirally and uniformly distributed on the cylindrical surface of the cutter part of the CNC milling cutter from left to right; a spiral angle is formed between the edge of each circumferential tooth body and the horizontal axis of the CNC milling cutter; each circumferential tooth body comprises a front angle I, a first rear angle II and a second rear angle II; and grooves are formed between each circumferential tooth body and the other three circumferential tooth bodies.

Owner:PINGHU CITY SHANTE THREAD TOOL

Belt removal tooling for pumping unit in oil field

InactiveCN105150162BAchieve installationAchieve disassemblyMetal-working hand toolsHydraulic cylinderThrust bearing

The invention discloses a belt detachment tool for a pumping unit in an oil field, and belongs to the field of petroleum machinery. The belt detachment tool comprises a driving device, a fixing device, a belt carrying device and an adjustment device. The driving device comprises a rotary hydraulic cylinder, an outer spline shaft and an inner spline shaft. The fixing device comprises an inner movable sheet bar and a clamping ring. The belt carrying device comprises an outer movable sheet bar and a static sheet bar. The adjustment device comprises a bearing platform, a thrust bearing, a screw nut, a lead screw, a bearing seat, a second bearing and a bearing cover. The movable sheet bars and the static sheet bar can break away and get close to realize the installation and detachment of a belt. The belt detachment tool can be installed on a belt wheel only through one bolt, so that operation is simple. A motor does not need to move in the detachment and installation process of the belt, it is guaranteed that the pre-tightening force of the belt is basically constant, the motor works stably, an operator only needs to drive a manual hydraulic pump and does not need to take part in other processes, safety risks are reduced, and operation efficiency is improved.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

automatic bread maker

The invention provides an auto brad maker, by which rice paste is made, and the rice paste is used to make rice bread and is obtained by regulating gelatinization of rice starch, and all rice starch molecule after absorbing water will not get into gel state because of heat change including temperature of enzyme activity. The steps is as following: a control part (29) controls heating to a heating part (26) and controls driving to a stirring part (24) respectively; and the temperature controlled by the heating part is set to the temperature of enzyme activity to produce rice paste, so as to make a rice bread.

Owner:PANASONIC CORP

A waste recovery and reuse device with a dust-proof structure

The invention discloses a waste recycling device with a dust-proof structure, relates to the technical field of recycling devices, and specifically relates to a waste recycling device with a dust-proof structure, including a sewage pool, a water storage barrel and A sewage pipe is installed above the feed inlet and the sewage pool, and a material storage room is installed at the front end of the sewage pipe. Press blocks are installed on the left and right sides of the storage room, and a push rod is installed in the middle of the press block. A water pump is installed at the front end of the water storage bucket, and the water storage bucket is located on the left side of the material storage room, and a flexible water pipe is connected above the water storage bucket. The waste recycling device with a dust-proof structure provides a movable storage space for the waste through the cooperation between the bucket, the flap and the lock pin. The cooperation between the three hydraulic columns and the steel rope can make the flap rotate along the outside of the lock pin, and can effectively put the waste inside the bucket into the inside of the feed port.

Owner:段亚斌

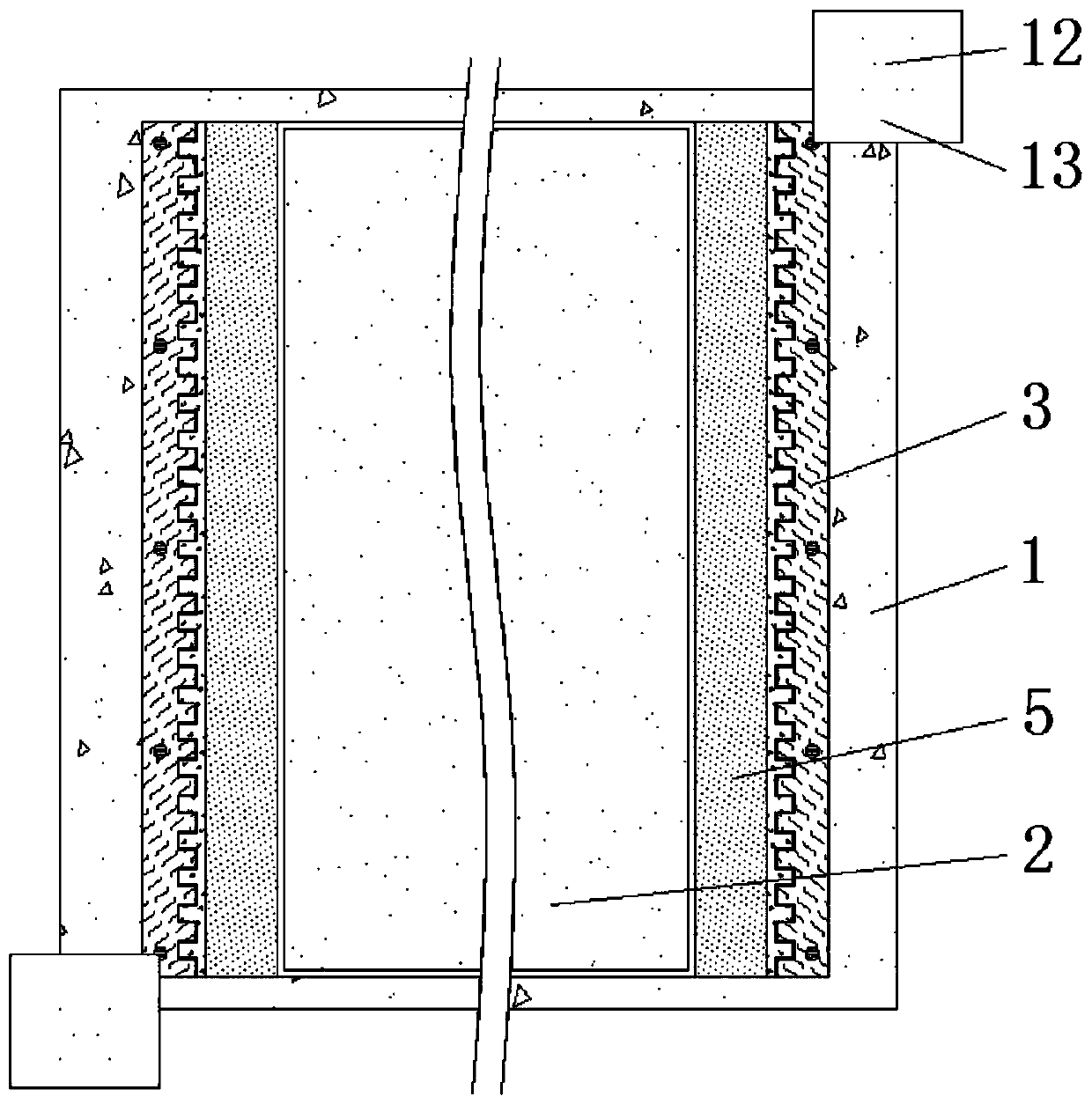

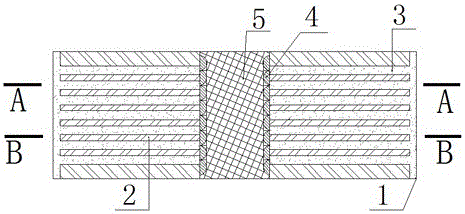

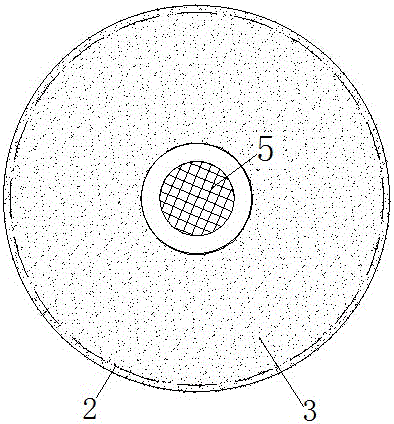

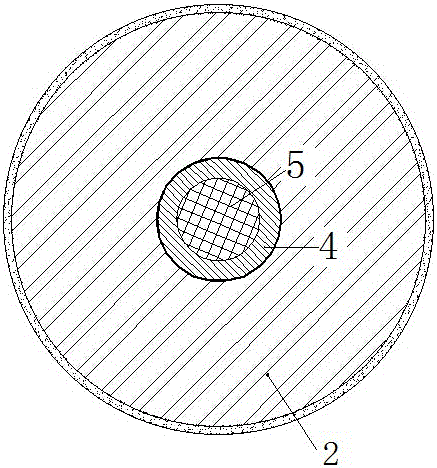

Lead Body Enclosed Bearing Constrained by Layered and Continuous Constraints

InactiveCN104018595BIngenious internal structureIncrease constraint stiffnessShock proofingStructural engineeringEngineering

The invention provides a lead enclosed type support constrained by loops continuously in a layered mode. The support solves the problems that when an existing lead core rubber support moves laterally and deforms greatly, resistant-lateral rigidity is low, horizontal resilience is low, a lead core is prone to damage and failure, and mechanical properties are poor. A support basal body is formed by alternately arranging a plurality of steel plate layers and rubber bonding layers up and down in an overlaid and bonding mode and is provided with at least one vertical hole, a plurality of constraint steel hoops are arranged in the holes and are of a closed circular structure, inner ring walls of the constraint steel hoops are of an arc structure, the vertical thickness of the constraint steel hoops is larger than the thickness of the rubber bonding layers, the upper surface of the constraint steel hoop on the uppermost layer is located between the upper end face and the lower end face of the steel plate layer on the uppermost layer, and a cavity inside the constraint steel hoops is filled with enclosed lead tightly attached to the cavity in an embedded mode. Lateral moving rigidity of the support is enhanced, meanwhile the problem of ductile fracture damage to the lead is avoided, and stress operation is stable and mechanical properties are excellent under reciprocating horizontal lateral moving.

Owner:TAIYUAN UNIV OF TECH

A ship connecting and disconnecting device and method thereof

ActiveCN107399408BWork quicklyStable workFloating buildingsHydrodynamic/hydrostatic featuresMarine engineeringControl system

The invention relates to a ship connecting and separating device and a method thereof, comprising a central control system, several connecting mechanisms, and several tightening mechanisms. The connecting mechanism and the tightening mechanism are arranged at equal intervals, and the central positions of the connecting mechanism and the tightening mechanism are on the same horizontal line; the central control system is composed of a PLC controller and a Beidou navigation system; the connecting mechanism includes a connecting plate, a connecting arm, support arm, crank lever, lift arm, the tightening mechanism is composed of a tightening assembly and a positioning assembly, the positioning assembly is installed directly below the tightening assembly, the tightening assembly, the positioning assembly When the assembly is installed, the distance between the fastening assembly and the positioning assembly is greater than the outer diameter of the spherical projection on the right side of the connecting arm. The invention has reasonable structure, convenient use, advanced and scientific method, and can effectively realize the connection and separation of ships through the invention.

Owner:YANGZHOU UNIV

High-frequency electric impact hammer

PendingCN113787491AImprove efficiencyReduce in quantityReciprocating drilling machinesConstructionsMachineMotronic

The invention relates to the technical field of fossil exploitation instruments, in particular to a high-frequency electric impact hammer which comprises an impact hammer assembly. The impact hammer assembly penetrates through the interior of a hammer body and comprises an acting head, a reset spring, an impact wheel and an electric motor, the outer surface of the acting head is sleeved with the reset spring, the reset spring is located in the hammer body, meanwhile, the impact wheel is located at one end of the acting head, and meanwhile, the electric motor is located at the bottom of the impact wheel. Three times of high-frequency impact can be achieved in the process of rotating a circle through the arranged impact wheel by means of the special structure of the impact wheel, the frequency is high, and therefore the efficiency of the impact hammer assembly is high, meanwhile the arranged impact hammer assembly is simple in structure, small in number of parts, economical, effective, low in production difficulty and easy to produce in batches, the arranged reset spring can help the acting head to reset on one hand and plays a role in buffering and damping on the other hand, and machine body loss of the whole device is reduced.

Owner:隆之古文化科技(苏州)有限公司

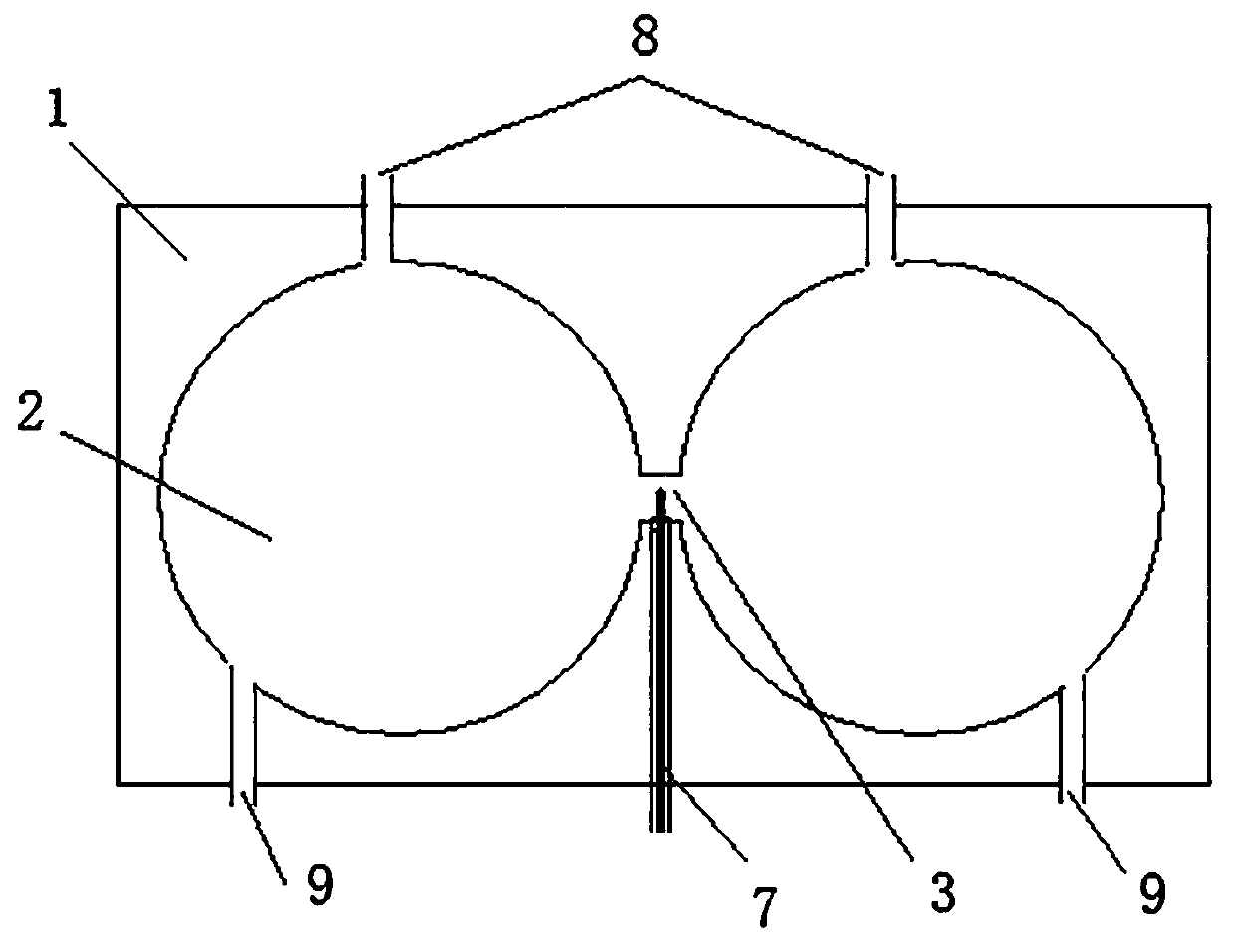

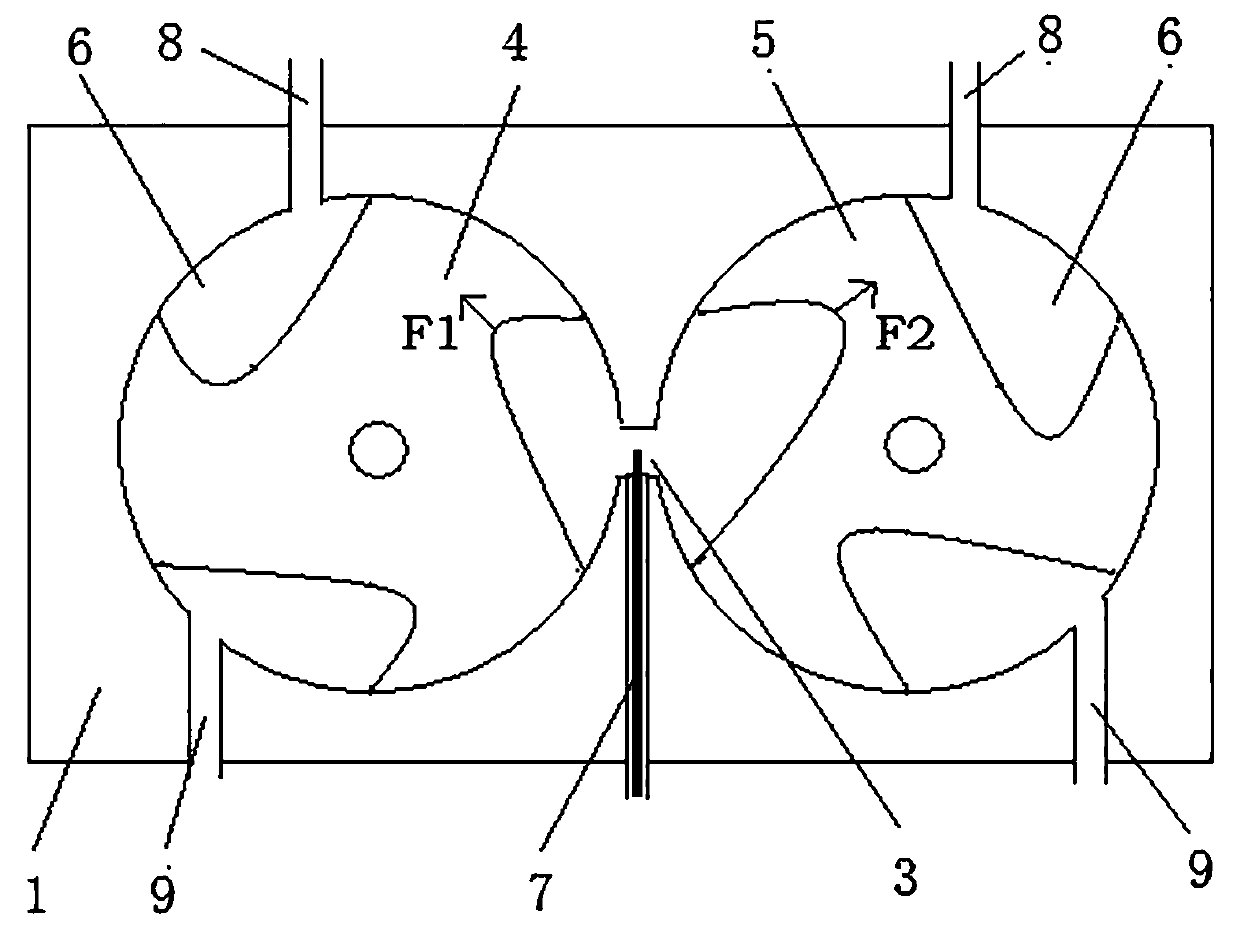

Combustible gas engine

ActiveCN111188682AHigh resistance to deflagration shockEasy to operateInternal combustion piston enginesGaseous engine fuelsCombustible gasMechanical engineering

The invention relates to a combustible gas engine. Pairs of rotating cavities are formed in a shell; rotors are rotatably installed in the rotating cavities, and a rotating shaft of at least one rotor is used for outputting torque; the rotors are provided with at least one concave part in the circumferential direction, the concave parts and the corresponding rotating cavities are sealed to form rotor air cavities, and the rotor air cavities are correspondingly filled with combustible gas and oxygen, or are correspondingly used for being filled with the combustible gas and oxygen; when the rotor air cavities formed in the rotating cavities formed in pairs are rotated to the adjacent position of the two rotating cavities, the rotor air cavities are communicated by a communicating channel; and when the rotors are rotated to the position where the rotor air cavities sequentially communicate with an inlet channel, the communicating channel and an exhaust channel, the air inflation, deflagration and exhaust processes are carried out, and the deflagration of the mixed gas drives the rotors to rotate. The rotation of the rotors only changes the position of the rotor air cavities, and thevolume of the rotor air cavities cannot be changed, so that it is ensured that the combustible gas cannot be deflagrated under pressure before reaching the deflagration position, and the stable and reliable operation of the combustible gas engine is ensured.

Owner:郑州机电工程学校

an air engine

A kind of air engine, described air engine comprises air engine main body, piston, moving valve, moving valve sleeve, exhaust valve plate, exhaust cover, valve ejector rod, camshaft seat, camshaft with cam, camshaft cover, Connecting rod and crankshaft etc. The air motor of the present invention has stable work, and has the advantages of simple structure, low manufacturing cost, low energy consumption, environmental protection and the like.

Owner:张谭伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com