Air engine and air engine system moving like breathing air

An air engine and air compressor technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of air engine instability, high manufacturing cost, and complex structure, and achieve simple structure, low manufacturing cost, and The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

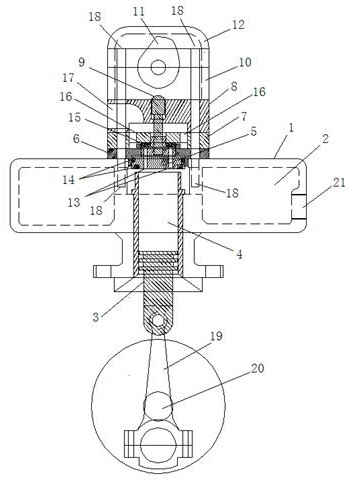

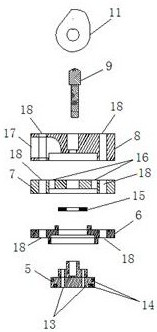

[0032] refer to Figure 1-Figure 4, an air engine, comprising an air engine main body 1, a piston 3, a moving valve 5, a moving valve sleeve 6, an exhaust valve plate 7, an exhaust cover 8, a valve push rod 9, a camshaft seat 10, a camshaft with a cam 11. Camshaft cover 12, connecting rod 19 and crankshaft 20;

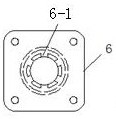

[0033] The main body of the air engine 1 is provided with a cylinder buffer air storage chamber 2 and a cylinder 4, the cylinder 4 communicates with the cylinder buffer air storage chamber 2, the piston 3 is nested with the cylinder 4, and is connected to the crankshaft through a connecting rod 19 20 connected, the main body of the air engine 1 is provided with a cylinder buffer air storage cavity intake hole 21; the movable valve 5 is provided with an exhaust hole I13, and the movable valve 5 is connected with the movable valve cover by the movable valve sealing ring 14 6 is assembled and connected, and is located above the cylinder 4; the movable valve cover 6 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com