Rotary cylinder engine

An engine and rotary cylinder technology, applied in the field of rotary cylinder engines, can solve the problems of short oil-gas mixing and combustion process, insufficient fuel combustion expansion, large emission pollution, etc., and achieve good mixing effect, sufficient fuel combustion and expansion, and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

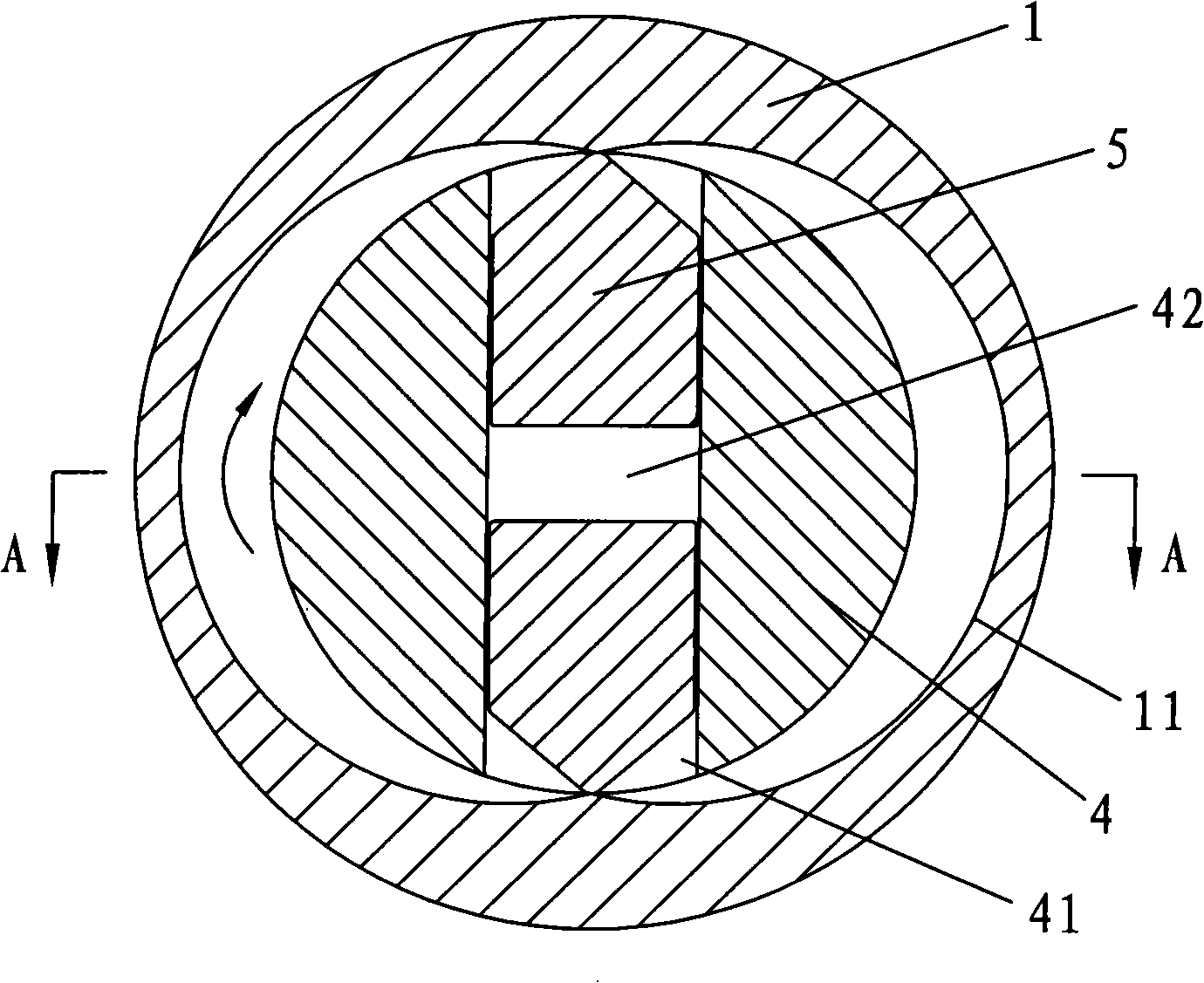

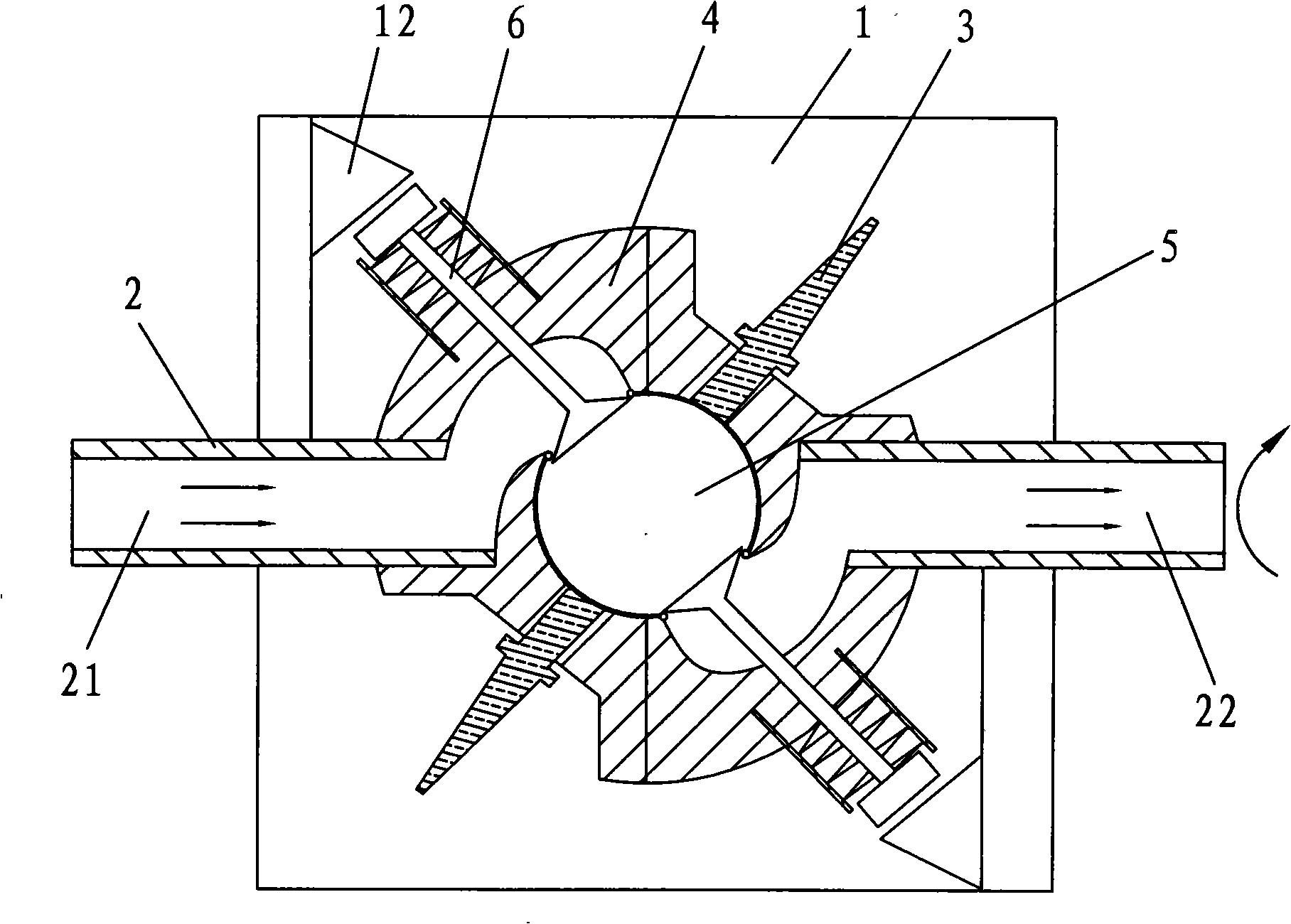

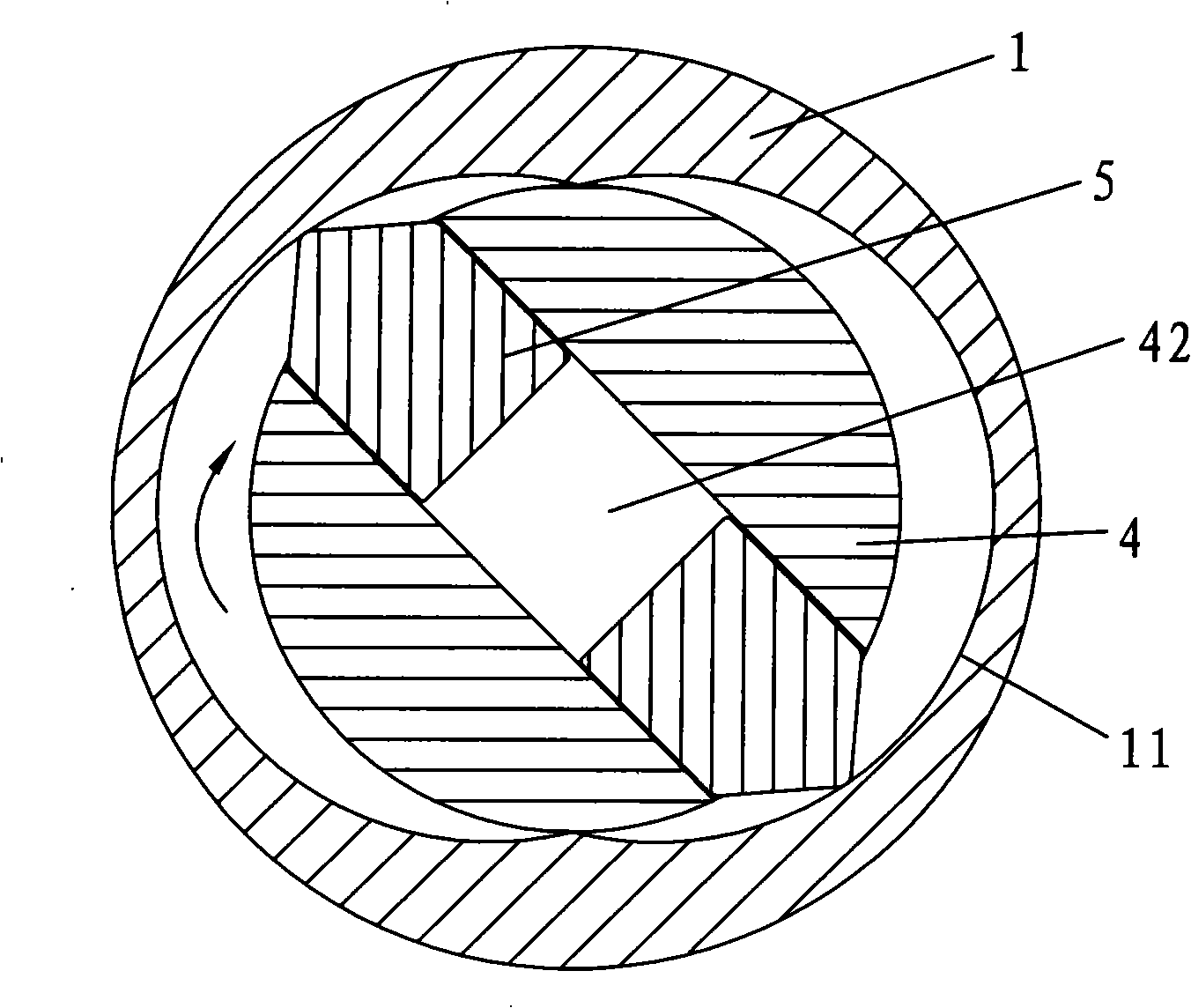

[0014] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1~3 , a rotary cylinder engine, which includes a stator 1, a rotating shaft 2 arranged in the inner cavity of the stator 1, and a spark plug 3. Both sides of the stator 1 are provided with eccentric arc-shaped walls 11, and the interior of the stator 1 is provided with a rotary cylinder 4. The cylinder 4 is coaxially fixed on the middle part of the rotating shaft 2, and the rotating cylinder 4 is provided with a radially penetrating cylinder 41, and two pistons 5 in opposite directions are slidably arranged in the cylinder 41, which can be radially outwardly drawn to the inner wall of the inner cavity of the stator 1. A combustion chamber 42 is formed between the two pistons 5 and the cylinder 41, the rotating shaft 2 is a hollow shaft, and its inner cavity communicates with the combustion chamber 42 on the rotary cylinder 4, and two spark plugs extending into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com