Screw tap

A tap and cone technology, applied in the field of new tools and new taps, can solve the problems of incomplete processing, chipping, blunt mouth, poor product quality, etc., and achieve the effect of correct design, good working performance and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

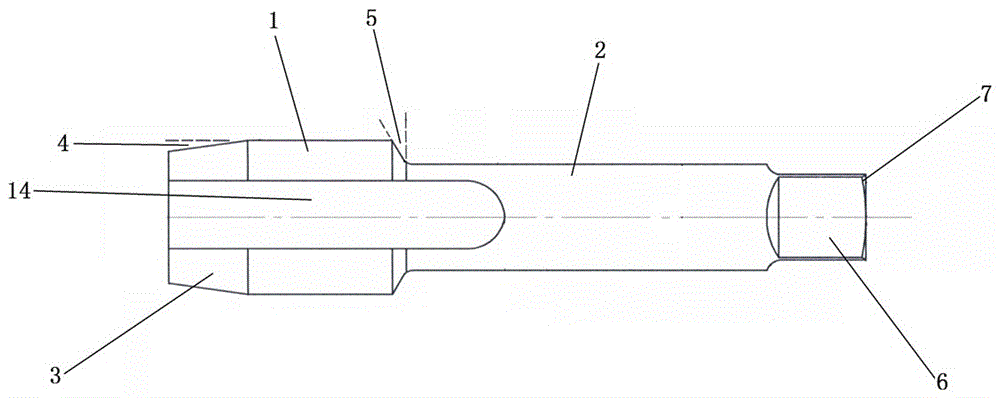

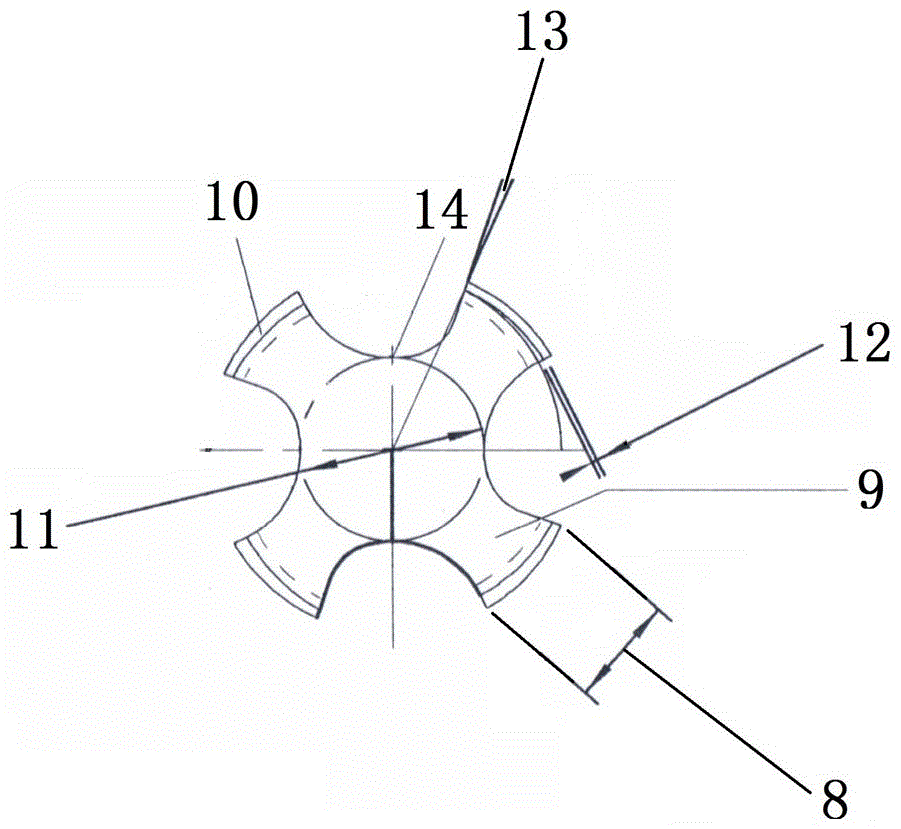

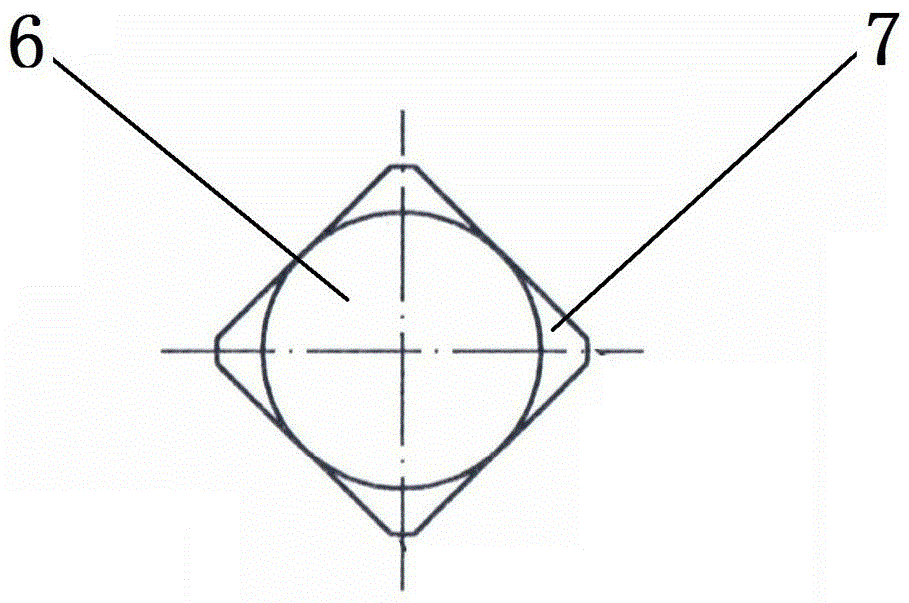

[0011] A tap, comprising a metal blade 1 and a metal shank 2, the metal blade 1 and the metal shank 2 are connected, the metal blade 1 is located on the left side of the tap, and the metal shank 2 is located on the right side of the tap, characterized in that The tap is in the shape of a cylinder and is placed horizontally in the illustration. The total length of the left and right sides of the tap is 115mm; there are four straight grooves 14 excavated from left to right on the cylindrical surface of the tap, and the four straight grooves 14 are evenly distributed on the On the cylindrical surface of the screw tap, four knife bands 9 are formed correspondingly; the right ends of the four straight grooves 14 are all arc-shaped, and the radius of the arc is 5 mm, so that the total lengths of the left and right sides of the four straight grooves 14 are respectively 56mm, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com