Computer numerical control (CNC) milling cutter with four teeth

A CNC milling and milling cutter technology, applied in milling cutters, manufacturing tools, milling machine equipment and other directions, can solve the problems of poor product quality, inadequate processing, unreasonable structure, etc., and achieve long service life, correct design and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

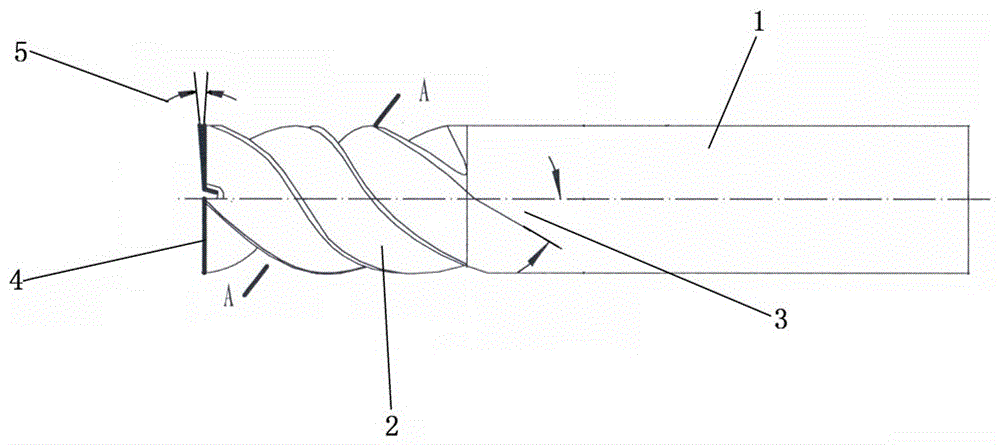

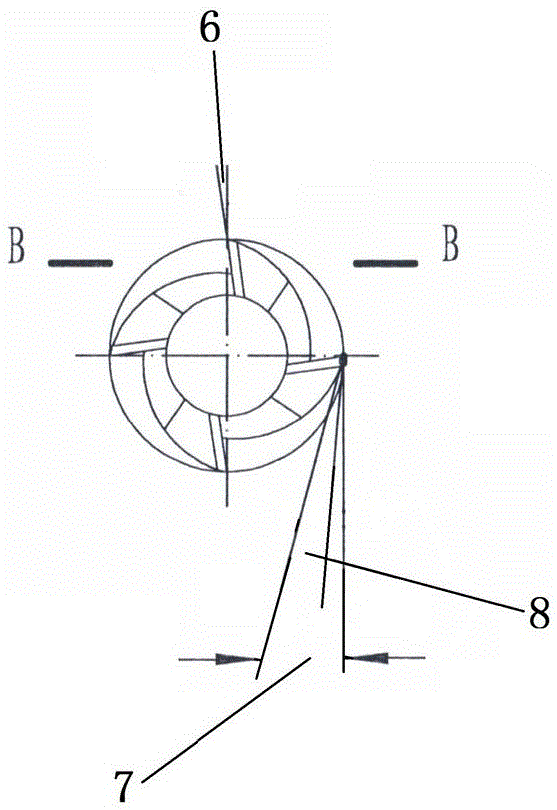

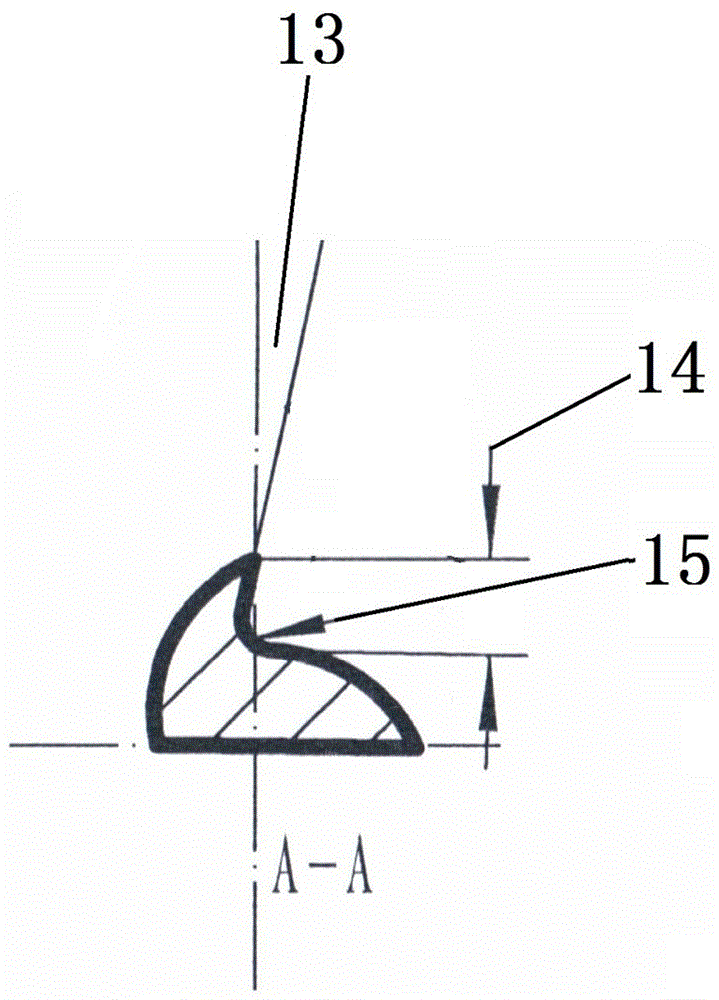

[0011] A CNC milling cutter with four teeth, including a metal shank 1 and a cutter 2, characterized in that the metal shank 1 is in the shape of a cylinder, placed horizontally in the figure, and is located on the right of the CNC milling cutter; the metal shank The diameter of 1 is 10㎜; while the cutter part 2 of the CNC milling cutter is processed by a metal cylinder, which is placed horizontally in the figure, located on the left part of the CNC milling cutter, and connected with the metal handle 1 of the CNC milling cutter; The diameter of the cutter part 2 of the CNC milling cutter is 10㎜, and the left and right lengths of the cutter part 2 are 25㎜, so that the total length of the left and right sides of the CNC milling cutter is 75㎜; the four end teeth of the four teeth of the CNC milling cutter Evenly distributed on the left end face 4 of the CNC milling cutter, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com