High-drilling-speed PDC drill bit

A technology of drilling speed and drilling head, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and mining, etc., can solve the problems of insufficient rock-breaking force, limited exploration speed, and limited drilling speed, etc. Feed speed, enhanced rock-breaking force, and faster cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

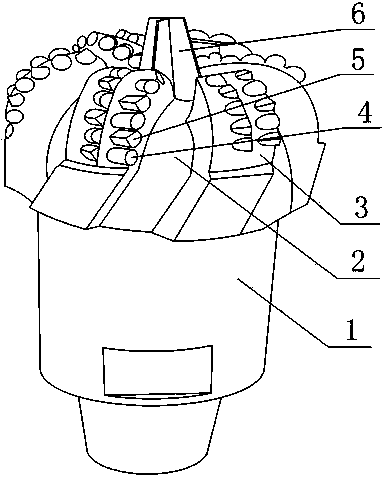

[0016] A PDC drill bit with high drilling speed, comprising a drill body 1, a blade 3 arranged on the drill body 1 and a chip removal groove 2 between two adjacent blades, the blade 3 is provided with two Rows of cutting teeth, each row of cutting teeth includes 3 circular cutting teeth 4 and 3 pointed cutting teeth 5, the exposure of the pointed cutting teeth 5 is higher than that of the circular cutting teeth 4, and the A drilling head 6 is arranged at the center of the top of the drill body 1, and the drilling head 6 is a herringbone drill.

[0017] In the technical solution of this embodiment, the existing technology is improved, the cutting teeth are set as circular cutting teeth 4 and pointed cutting teeth 5, and the exposure of the pointed cutting teeth is higher than that of the circular cutting teeth, When drilling, the sharp cutting teeth can first cut the rock formation, enhance the cutting ability of the formation, and increase the drilling speed. Two rows of cutt...

Embodiment 2

[0019] As shown in Question 1, a PDC drill bit with a high penetration rate, this embodiment is improved on the basis of Embodiment 1: the circular cutting teeth 4 and pointed cutting teeth 5 on each row of cutting teeth are arranged alternately. The circular cutting teeth 4 and the pointed cutting teeth 5 are alternately arranged, so that the pointed cutting teeth are evenly stressed on the rock formation, and the service life of the pointed cutting teeth is improved.

[0020] The exposure of the pointed cutting teeth 5 is 1.0-1.5 mm higher than that of the circular cutting teeth 4 . If the sharp cutting teeth are exposed higher, the circular cutting teeth start to cut after the depth of the ground cutting needs to be deep, which makes the efficiency slower. If the exposure of the sharp cutting teeth is low, the effect of rock breaking force is not obvious.

Embodiment 3

[0022] As shown in Question 1, a PDC drill bit with a high drilling speed, this embodiment is improved on the basis of the above embodiment: the drill bit 6 is provided with reinforcing ribs. Because the drill bit body is herringbone, the petals of the drill bit body are easily damaged during the drilling process, and the ribs are used to connect the petals to increase their service life. Due to the need to connect the ribs, in Embodiment 1, the herringbone drill bit is used, which is also beneficial to the fixing of the ribs compared to other forms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com