Liquid drop and solid plate oblique collision testing device

A collision test, solid technology, applied in the aviation field, can solve problems such as large differences, complex device structure, and inability to carry out visual test of collision between oil droplets and cavity walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with specific implementation examples.

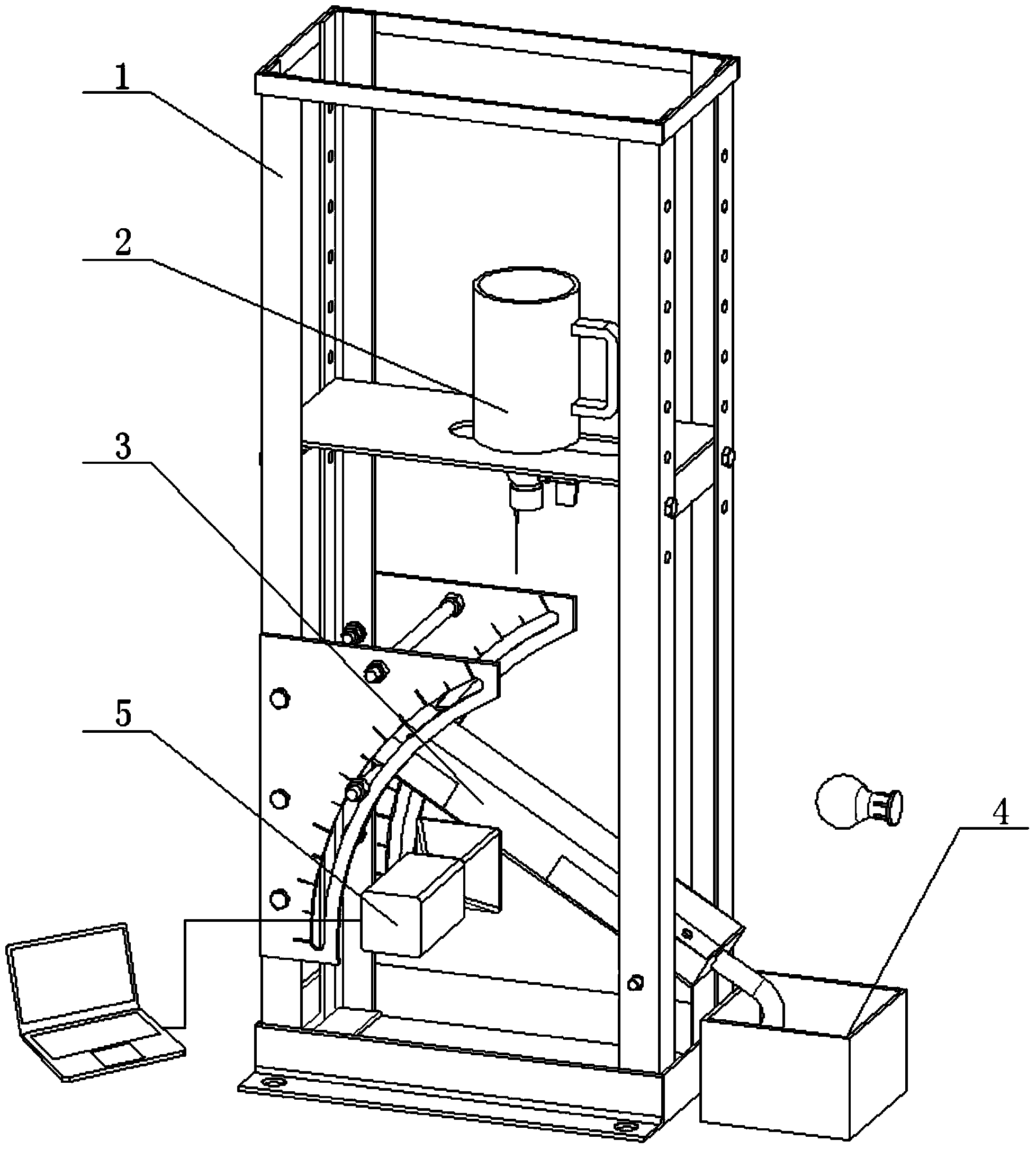

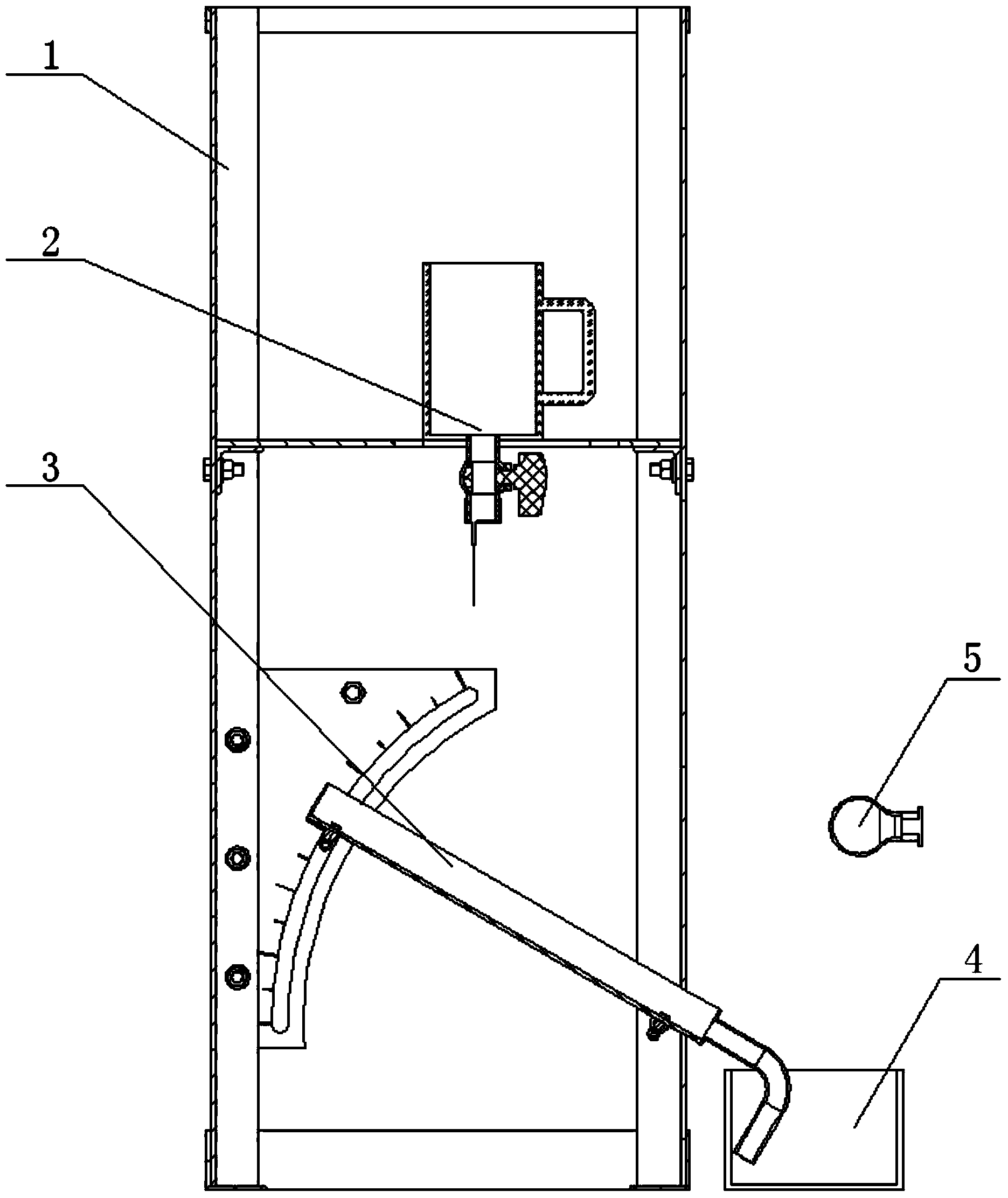

[0031] 1. Refer to the attached figure 1 with attached figure 2 , The droplet and solid plate oblique impact test device described in this embodiment includes a support frame 1, a droplet generating part 2, an angle-adjustable solid plate part 3, an oil return part 4, and an illumination camera system 5.

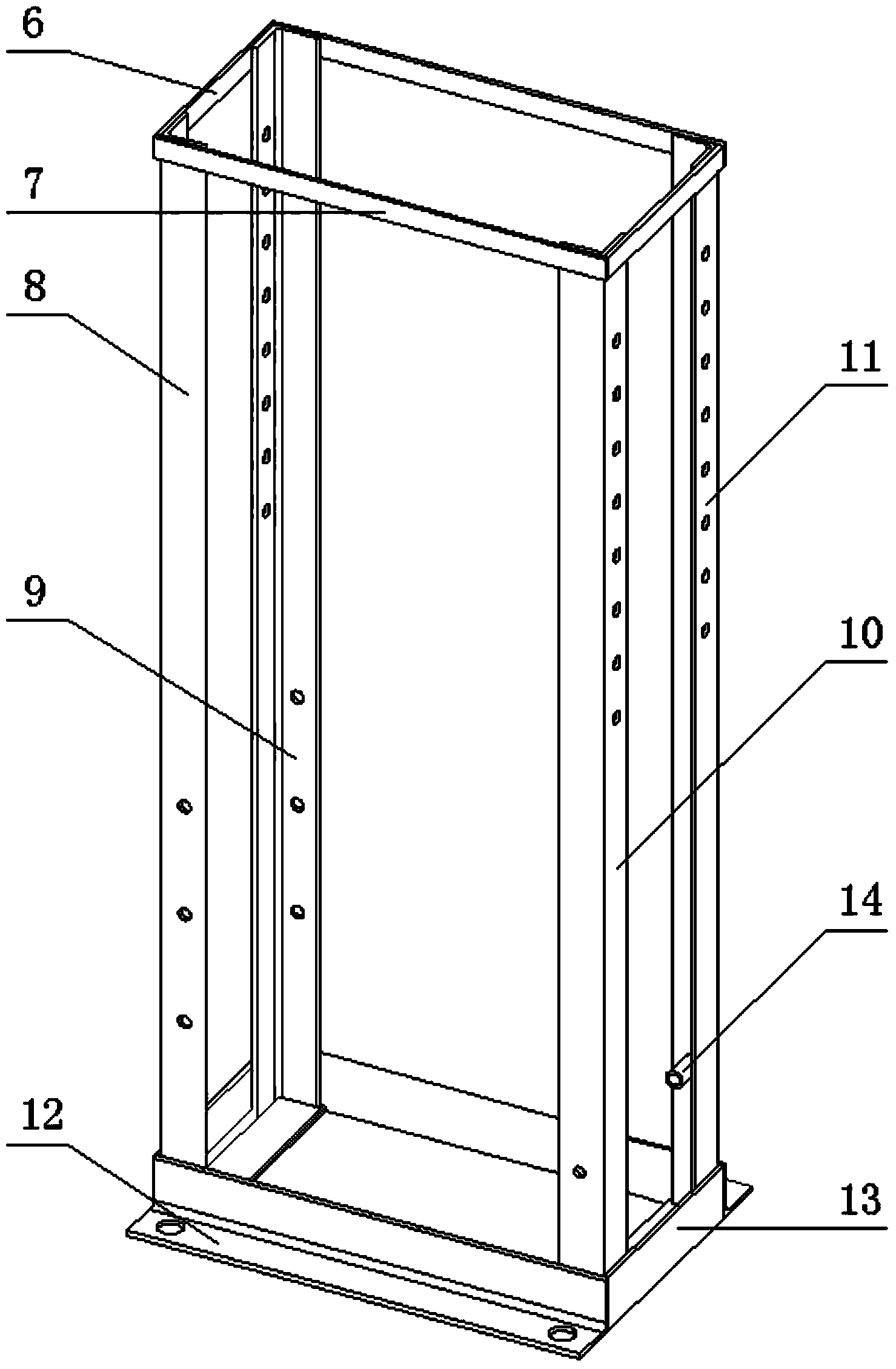

[0032] 2. Refer to the attached image 3 , Support frame 1 is made of short upper fence 6, long upper fence 7, one guide rail 8, two guide rails 9, three guide rails 10, four guide rails 11, long base plate 12, short base plate 13, and axle sleeve 14 is welded. Ensure the parallelism between guide rail 1, guide rail 2, guide rail 3, and guide rail 4. When welding the bushing 14, pay attention to coincide with the axis line of the holes on guide rail 3 10 and guide rail 4 11. There are two through holes on the long bottom plate 12....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com