Method for measuring flux of magnetic element and device thereof

A magnetic component and magnetic flux technology, applied in the field of magnetic flux testing, can solve problems such as poor numerical repeatability and accuracy, low test efficiency, and high labor intensity, and achieve high repeatability and accuracy, high test efficiency, and labor intensity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

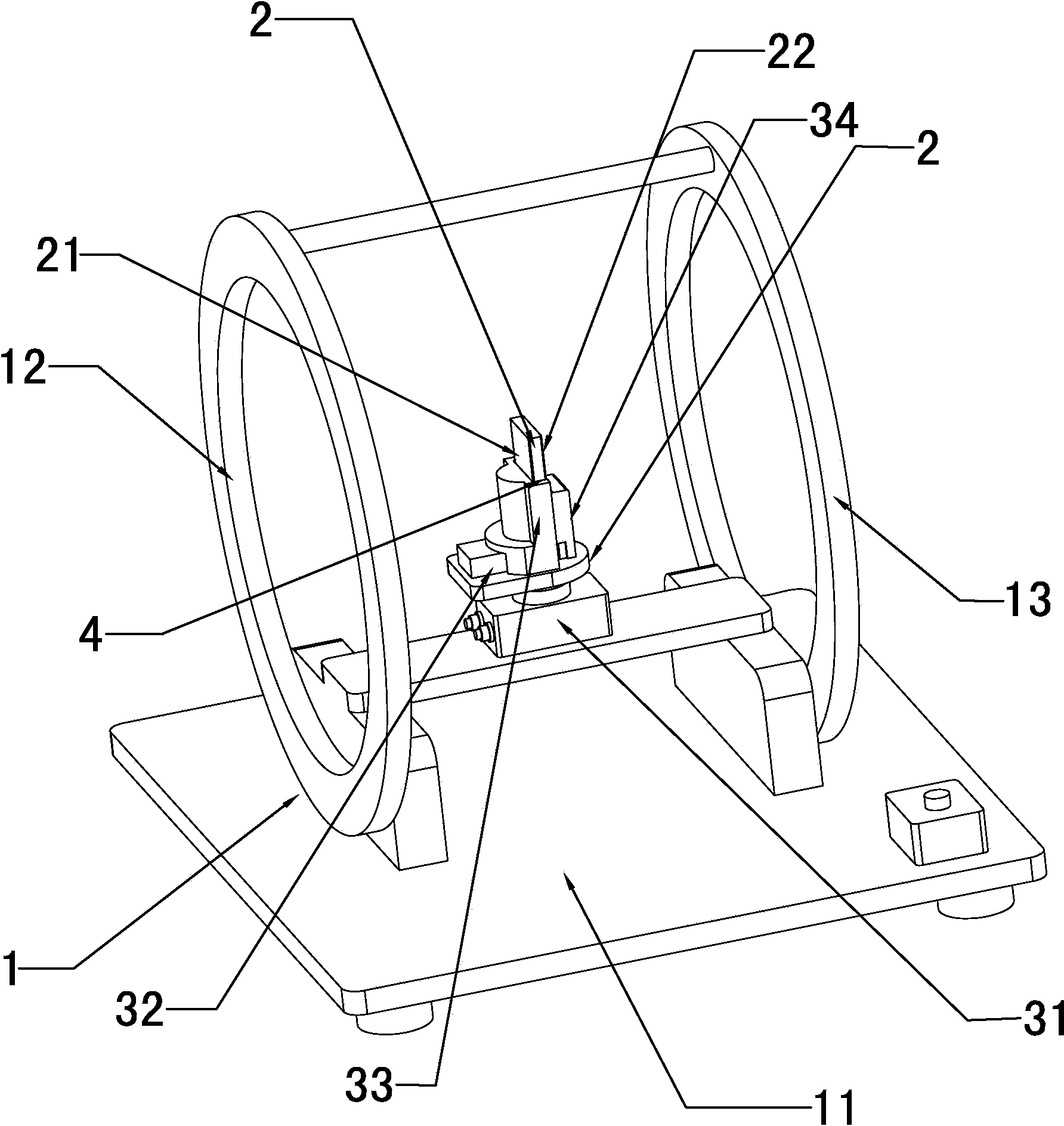

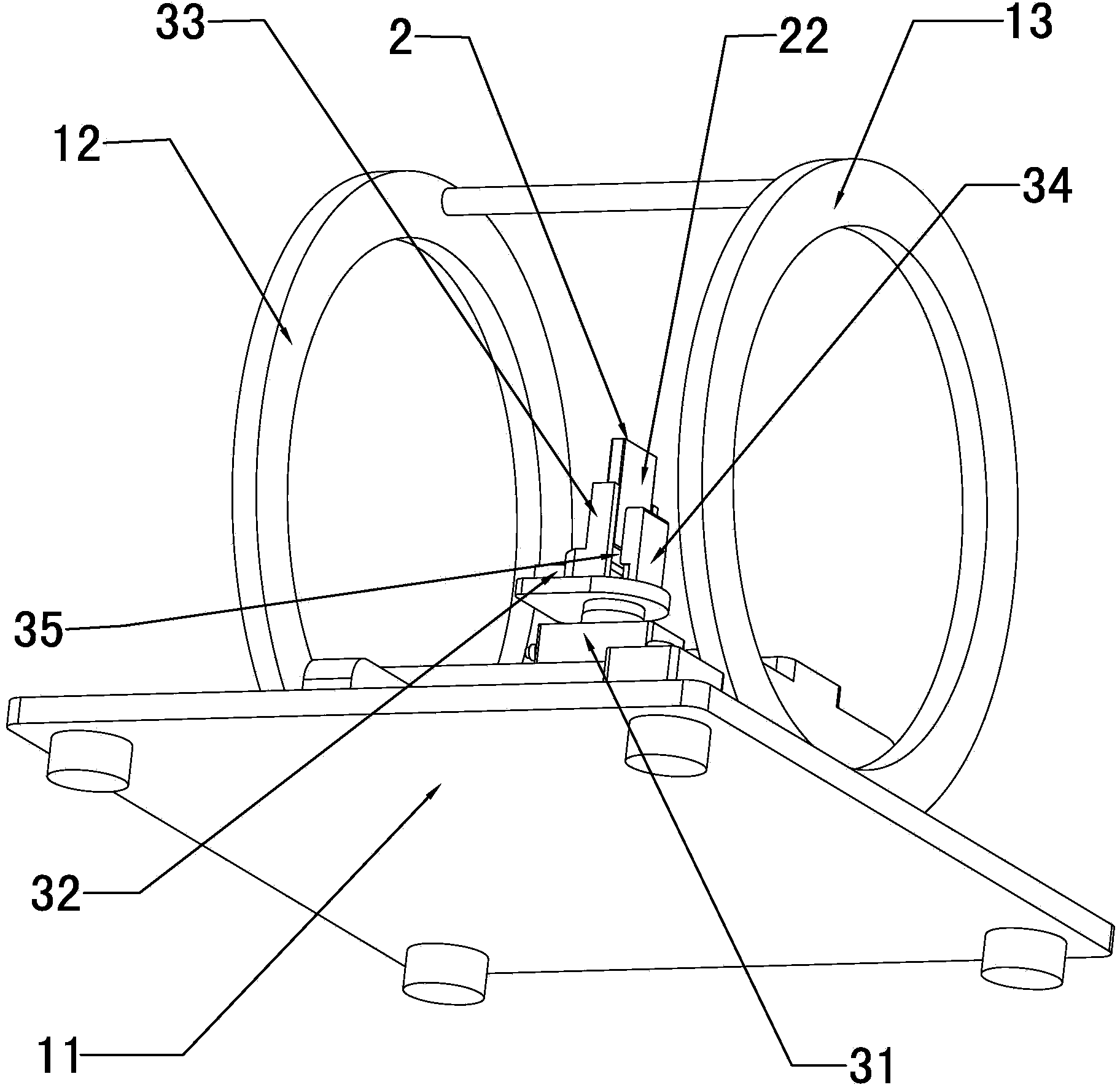

[0036] Embodiment one: if figure 1 and figure 2 As shown, a method for measuring the magnetic flux of a magnetic element comprises the following steps:

[0037] ① Connect the Helmholtz coil 1 to the fluxmeter, the Helmholtz coil 1 includes a support base 11, a first coil 12 and a second coil 13 coaxially arranged at the left and right ends of the support base 11;

[0038] ② Put the magnetic element 2 to be tested into the Helmholtz coil 1, the magnetization direction of the magnetic element 2 to be tested is along the axial direction of the Helmholtz coil 1 and the magnetic element 1 to be tested is located between the first coil 12 and the second coil 1. In the middle of the coil 13, the end face of the magnetic element 2 to be tested facing the first coil 12 is the first end face 21, and the end face of the magnetic element 2 to be tested facing the second coil 13 is the second end face 22;

[0039] ③Clear the fluxmeter to zero;

[0040] ④ Use the flip mechanism 3 to tur...

Embodiment 2

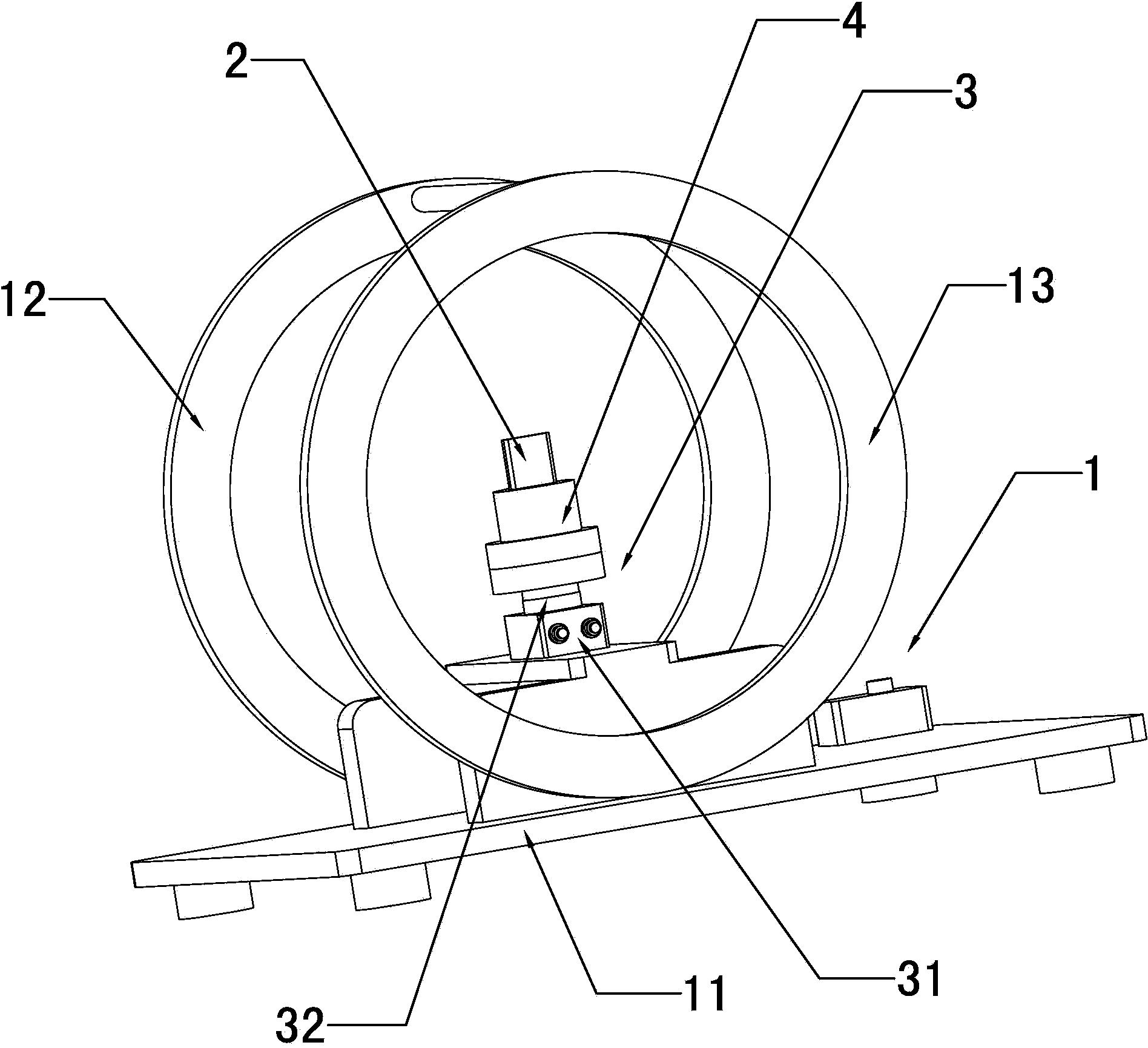

[0045] Embodiment two: if image 3 As shown, a method for measuring the magnetic flux of a magnetic element comprises the following steps:

[0046] ① Connect the Helmholtz coil 1 to the fluxmeter, the Helmholtz coil 1 includes a support base 11, a first coil 12 and a second coil 13 coaxially arranged at the left and right ends of the support base 11;

[0047] ② Put the magnetic element 2 to be tested into the Helmholtz coil 1, the magnetization direction of the magnetic element 2 to be tested is along the axial direction of the Helmholtz coil 1 and the magnetic element 1 to be tested is located between the first coil 12 and the second coil 1. In the middle of the coil 13, the end face of the magnetic element 2 to be tested facing the first coil 12 is the first end face 21, and the end face of the magnetic element 2 to be tested facing the second coil 13 is the second end face 22;

[0048] ③Clear the fluxmeter to zero;

[0049] ④ Use the flip mechanism 3 to turn the magnetic ...

Embodiment 3

[0059] Embodiment 3: In this embodiment, on the basis of Embodiment 1 and Embodiment 2, a mechanical arm for loading the magnetic element 2 into the positioning platform 4 and taking the magnetic element 2 out of the positioning platform 4 is added, thus Improve the automation degree of the device and improve the test efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com