Chuck for machine tool for machining tubular, rotating workpiece

A chuck and workpiece technology, which is applied to the chuck field of machine tools for processing tubular and rotating workpieces, can solve the problems of large diameter and length of the chuck, and achieve the effect of compact structure type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

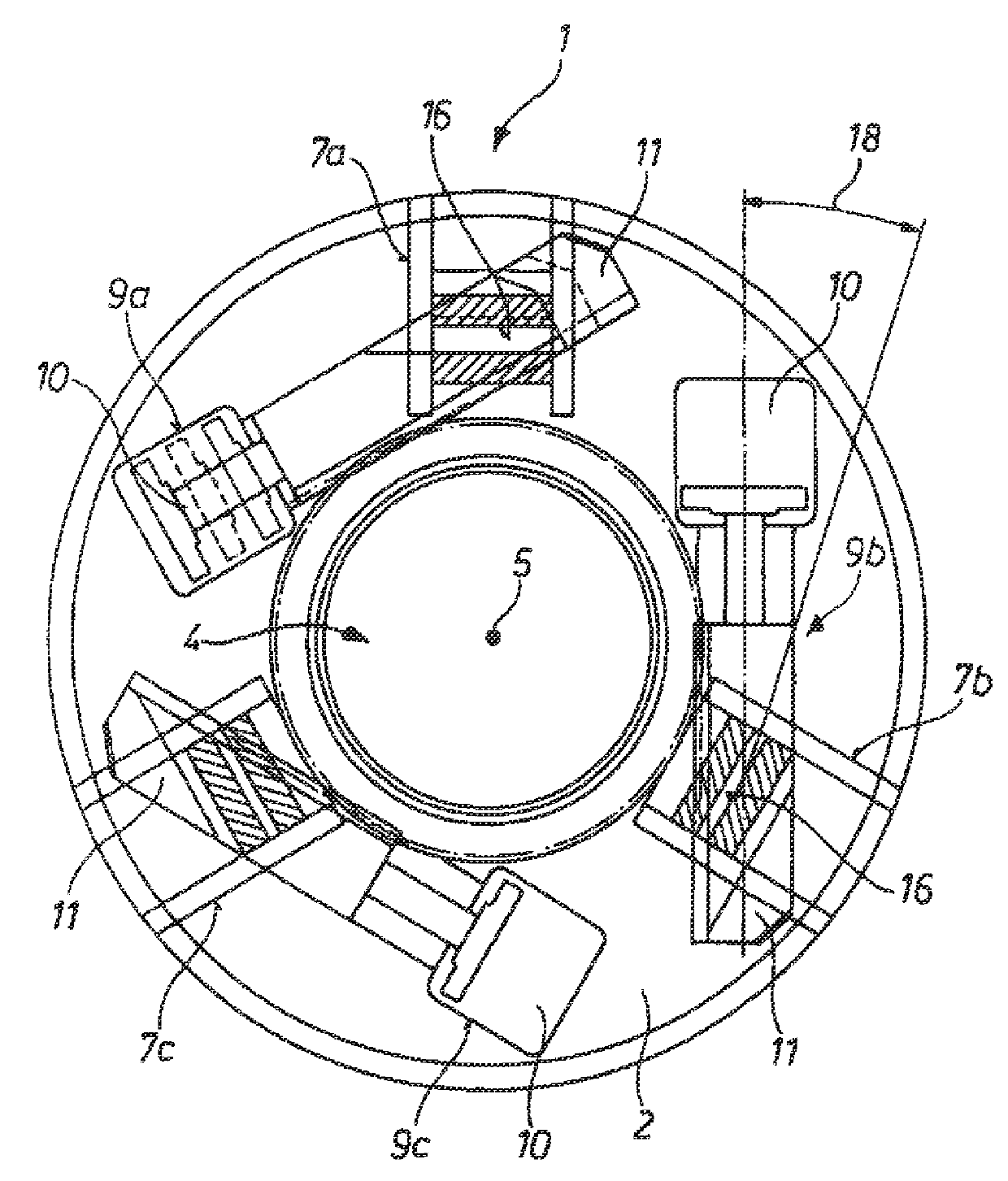

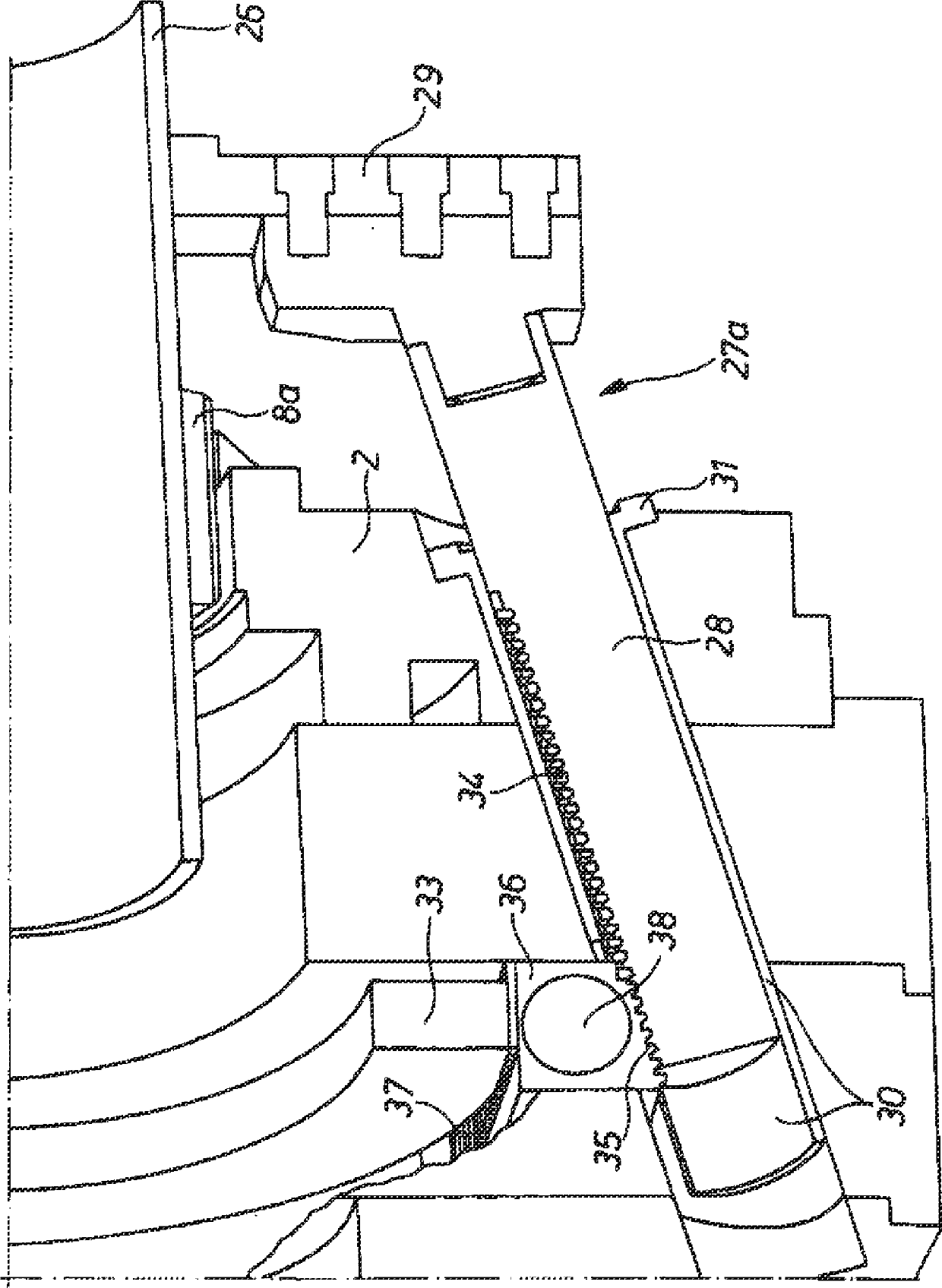

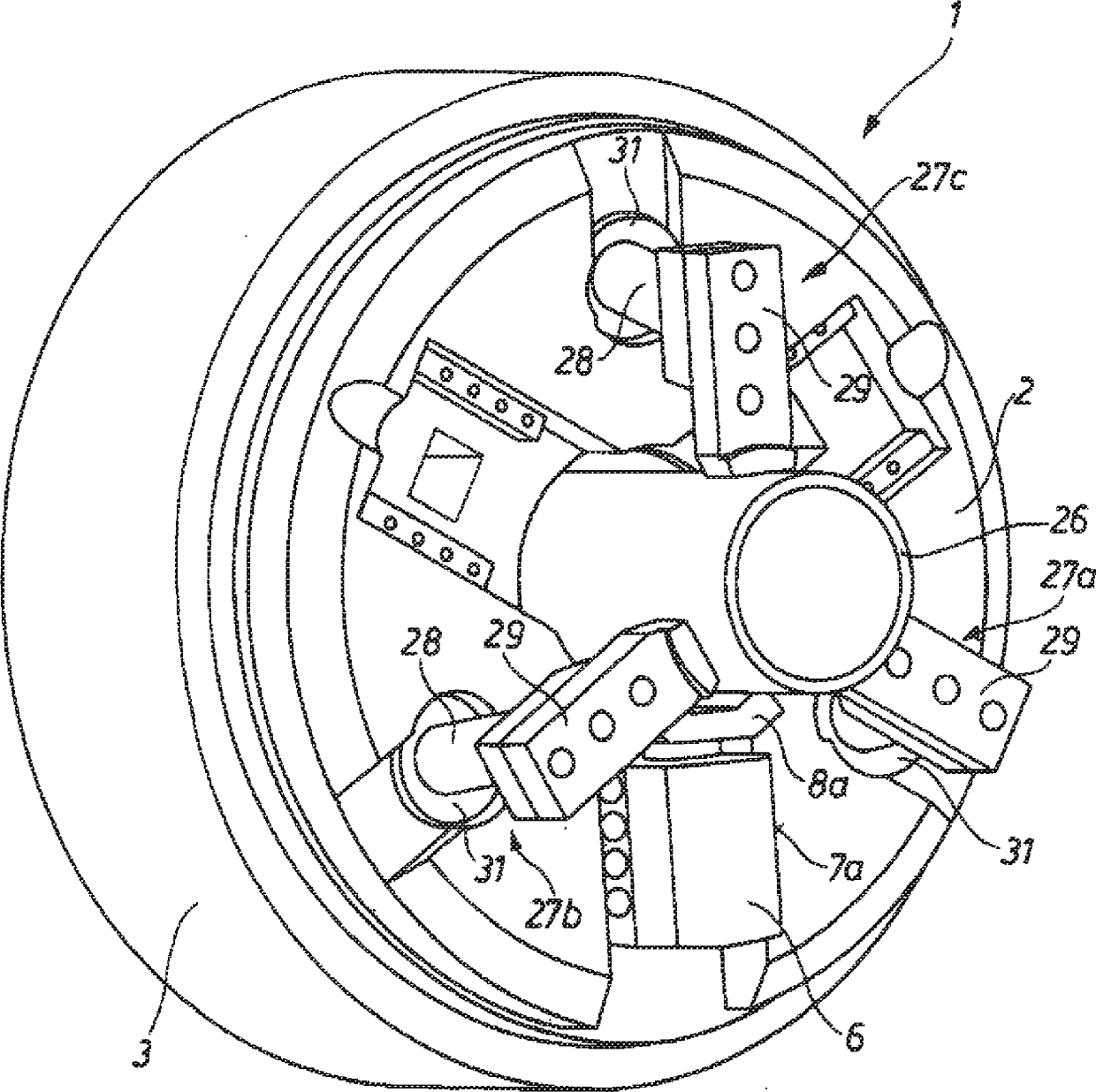

[0022] Machine tools for cutting threads or threaded joints at pipe ends figure 1 The chuck 1 shown in is composed of a top plate 2 and a rearwardly coupled housing ring 3 . In order to accommodate the tube 26 to be processed (see figure 2 ), the chuck 1 has a central through hole 4 whose center 5 coincides with the axis of rotation of the tube rotating in the chuck. Arranged on the end face of the top plate 2 evenly distributed over the circumference are three clamping slides with clamping jaws 8 a, b, c, which are covered by a cover 6 and can be adjusted radially to the center or axis of rotation 5 7a,b,c which center the tube on the center or axis of rotation 5 (see Figure 6 ) to clamp.

[0023] In order to adjust the clamping slides 7a, b, c with the clamps 8a, b, c in the direction of the center or the axis of rotation 5 of the chuck 1, each clamping slide 7a, b, c is tangential to The axis of rotation 5 is associated with transverse slides 9 a, b, c integrated in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com