Carbonation device and method of carbonation using the same

一种设备、碳化反应的技术,应用在化学仪器和方法、锂碳酸盐;/酸式碳酸盐、碳酸盐/酸式碳酸盐的制备等方向,能够解决喷嘴堵塞、过度消耗、难以实现连续方法等问题,达到避免堵塞、抑制过度消耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

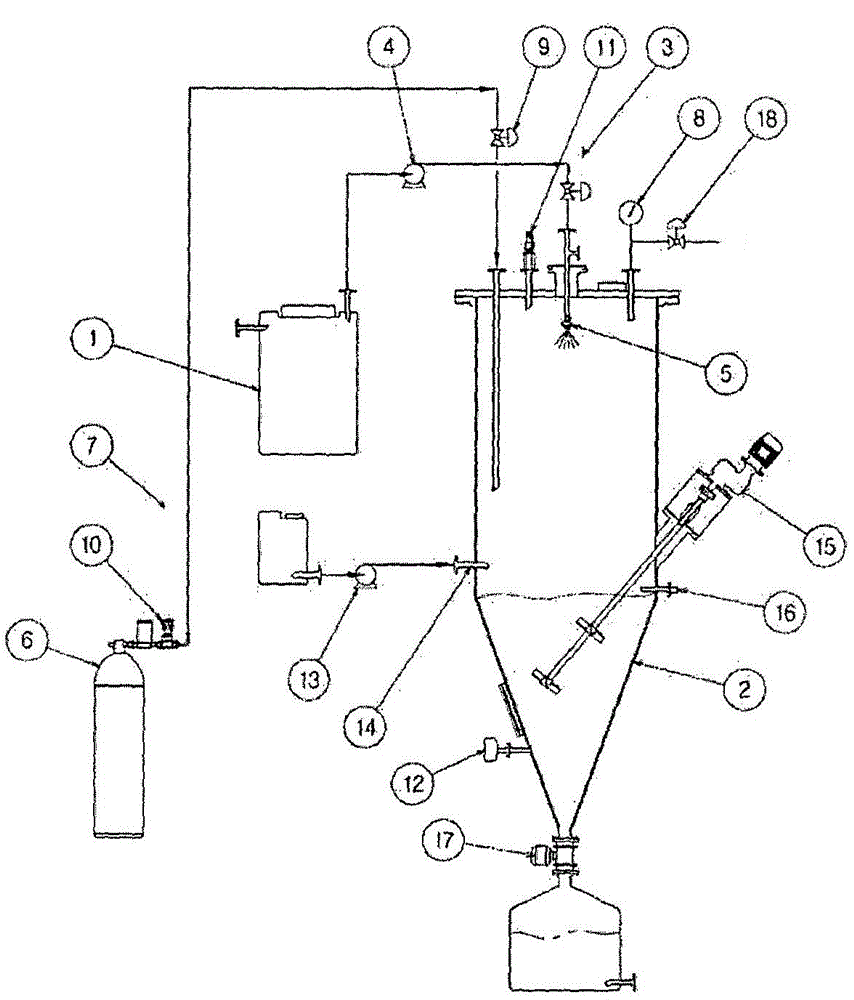

[0052] Embodiment of the invention

[0053] Cross-references to related applications

[0054] This application claims priority from Korean Patent Application No. 10-2012-0002181 filed with the Korean Intellectual Property Office on January 6, 2012, which is incorporated herein by reference in its entirety.

[0055] Exemplary embodiments of the present invention will be described in detail below. However, these embodiments are only exemplary, and the present invention is not limited thereto.

[0056] One embodiment of the present invention can provide a carbonization equipment, which includes: a storage tank, which stores the solution of the carbonization target; a droplet spray device, which sprays the solution of the carbonization target in the storage tank; There is a droplet spray device and filled with carbonization gas, the carbonization gas has a predetermined pressure, and the slurry is provided through the carbonization reaction of the carbonization object solution s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com