Fixation cooling machine

A cooling machine and degreening technology, which is applied in tea treatment before extraction, etc., can solve the problems of tea quality decline, slow heat dissipation of degreened leaves, uneven turning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

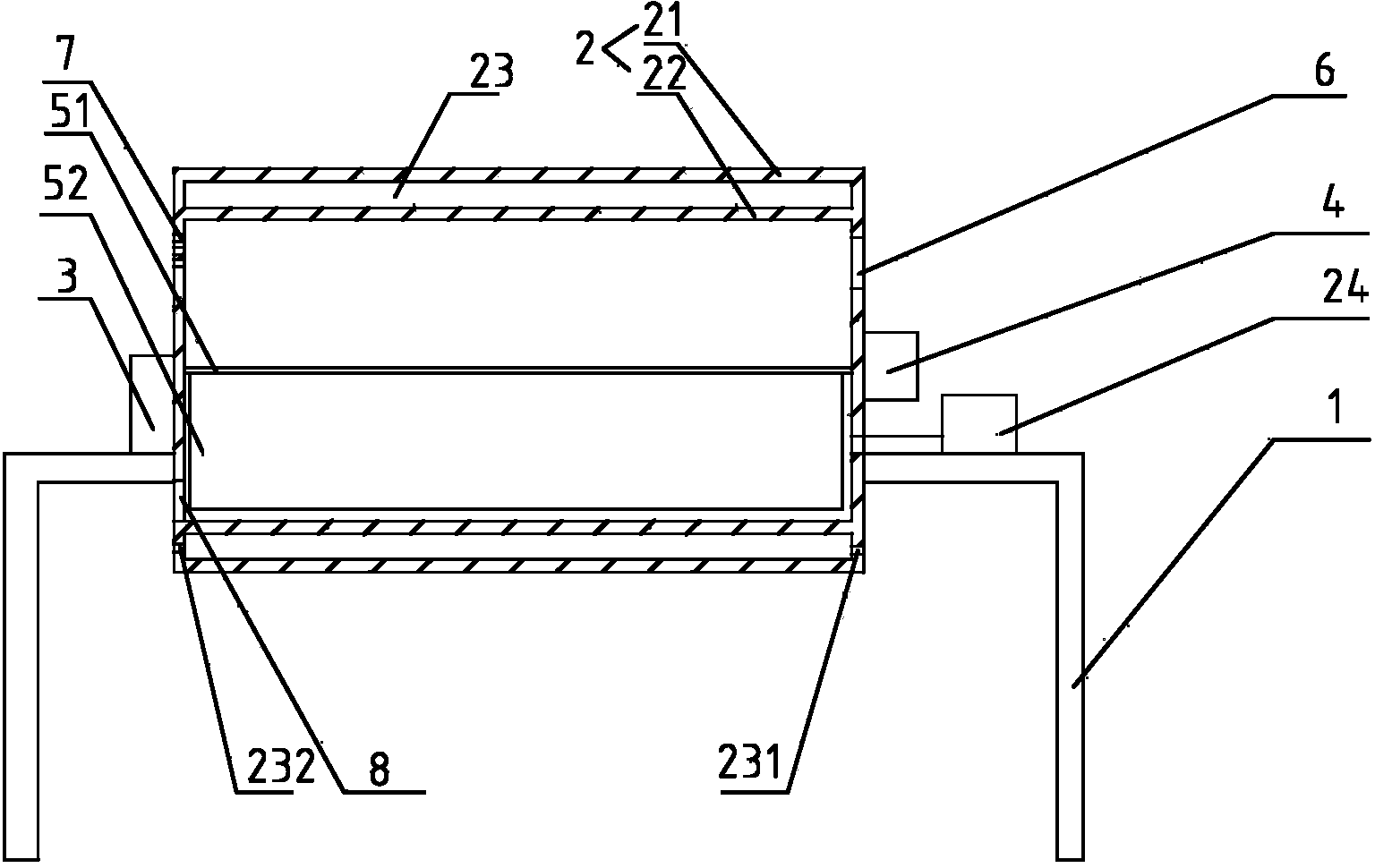

[0018] refer to figure 1 , a kind of finishing cooling machine shown, comprises frame 1, is provided with material cylinder 2 on frame 1, and the upper end of material cylinder 2 is provided with material inlet 6, is connected with sealing cover on material inlet 6, and material cylinder 2 lower end is provided with There is a discharge port 8, which is connected with a cover body, and the opposite ends of the barrel are respectively provided with an air inlet and an exhaust hole 7, and the exhaust port is a capillary hole, and the air inlet is connected with a blower fan 24. The barrel 2 is connected with a drive device 3 for driving the barrel to rotate, the drive device 3 is arranged on the frame 1, and a stirring device is arranged in the barrel 2. Open the sealing cover, add the green leaves into the barrel 2 and cover the sealing cover, the driving device 3 drives the barrel 2 to roll, the stirring device turns the green leaves, and the fan 24 works at the same time, whi...

Embodiment 2

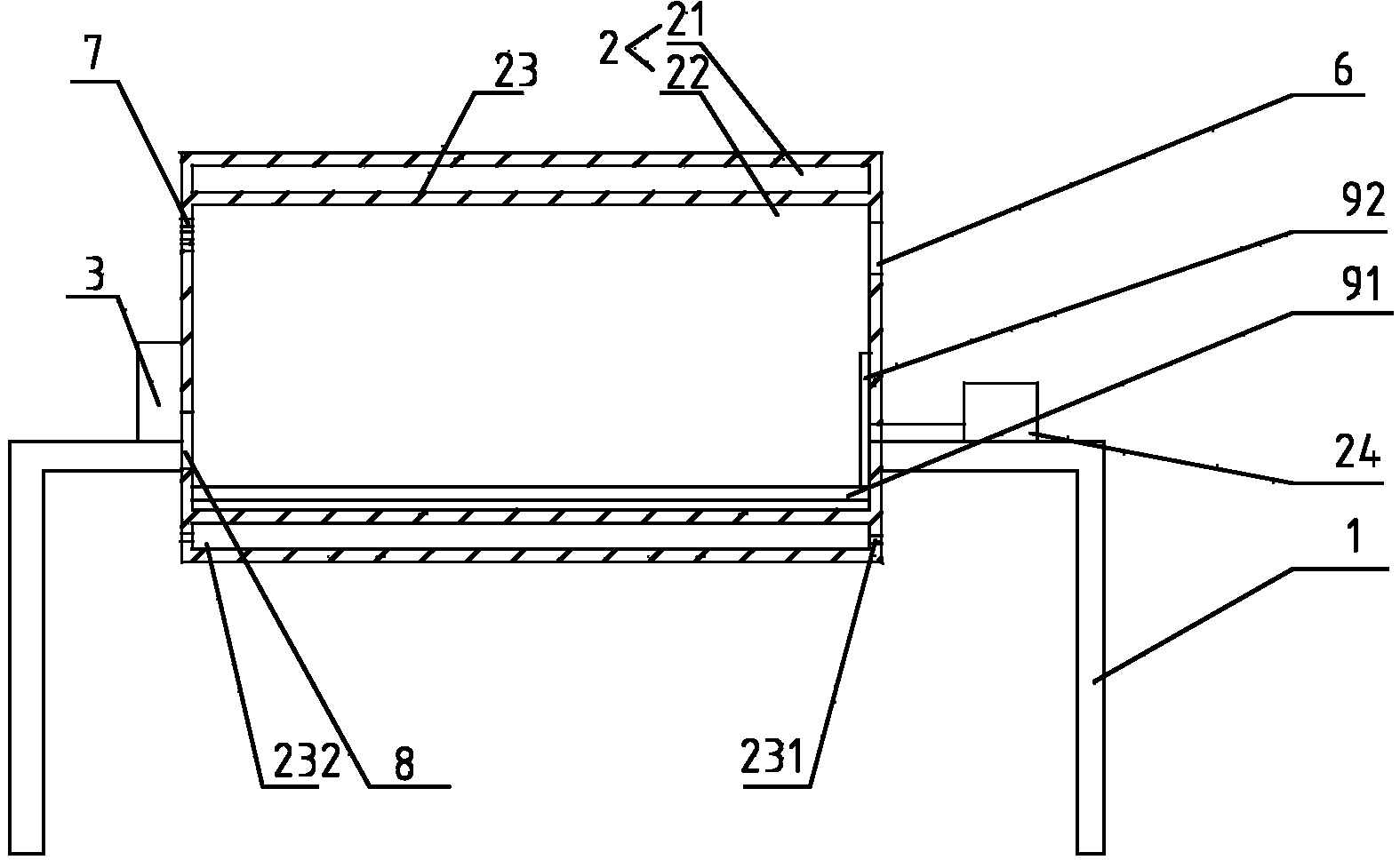

[0023] refer to figure 2 , a kind of finishing cooling machine shown, comprises frame 1, is provided with material cylinder 2 on frame 1, and the upper end of material cylinder 2 is provided with material inlet 6, is connected with sealing cover on material inlet 6, material cylinder 2 lower ends A discharge port 8 is provided, and a cover body is connected to the discharge port 8. An air inlet and an exhaust hole 7 are respectively provided at opposite ends of the barrel 2. The exhaust port is a capillary hole, and a fan 24 is connected to the air inlet. , The barrel 2 is connected with a driving device 3 for driving the barrel to rotate, and a stirring device is arranged inside the barrel 2. The stirring device in this embodiment includes a shaking plate 91 on which a pneumatic muscle 92 is connected. The pneumatic muscle 92 drives the shaking plate 91 to vibrate, thereby flipping the green leaves, and the pneumatic muscle has good dynamic characteristics under heavy load,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com