Press type rebound slide rail

A push-type, slide-rail technology, applied in furniture parts, home appliances, drawers, etc., can solve problems such as jamming, damage to the elastic parts of the rebound device, affecting the service life of the slide rail, etc., to extend the service life, increase the tightness, The effect of protecting elastic parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

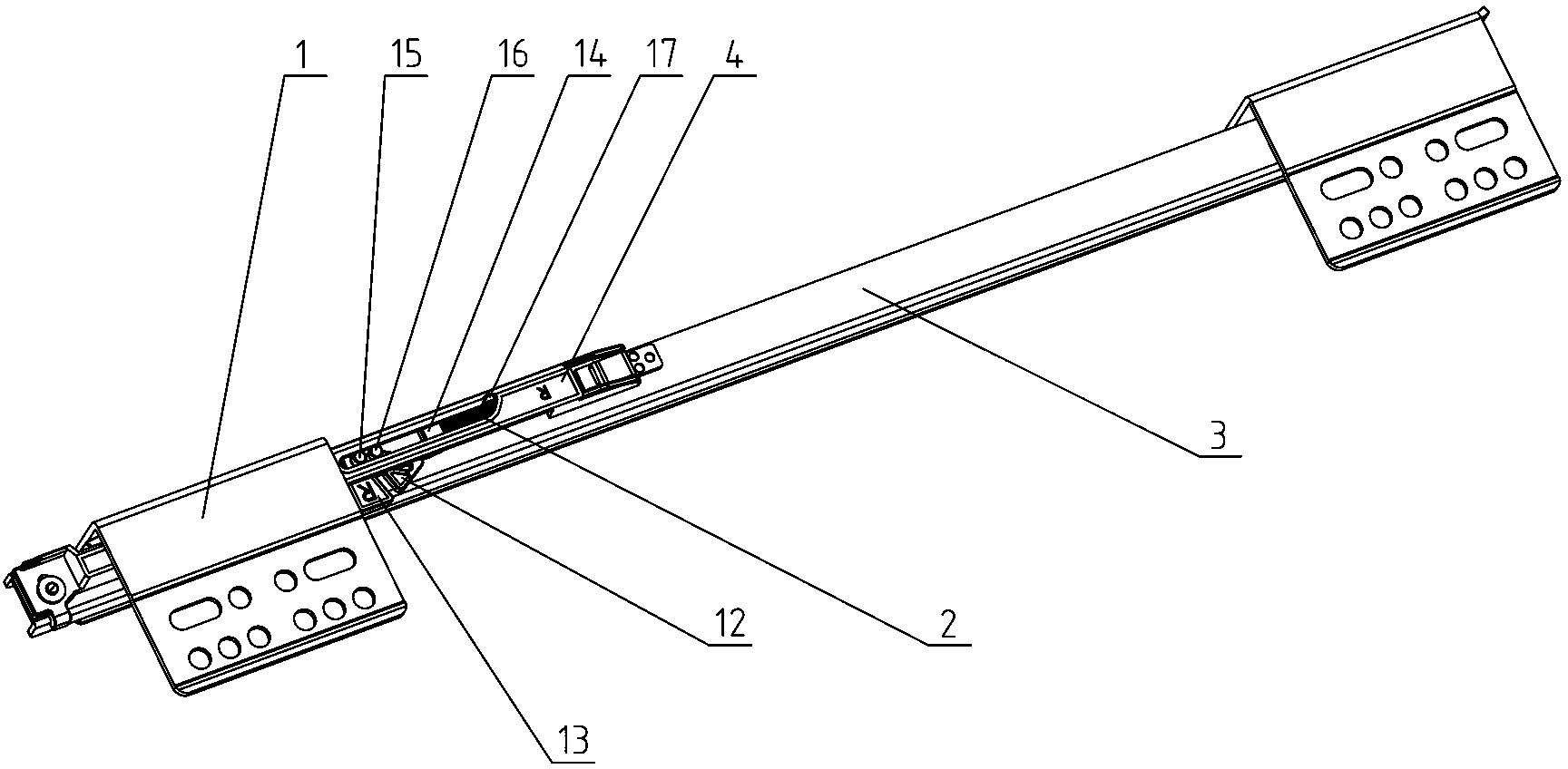

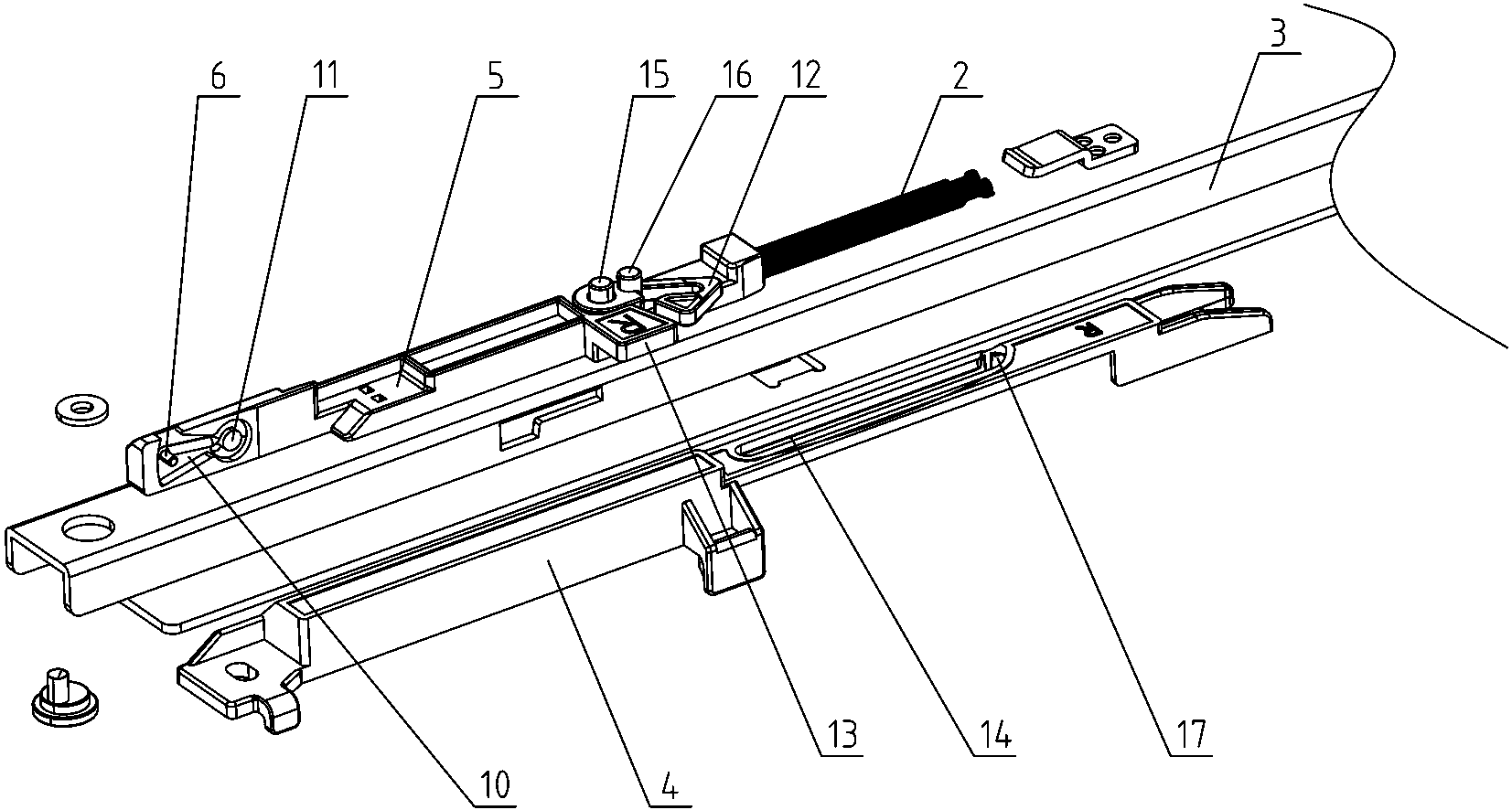

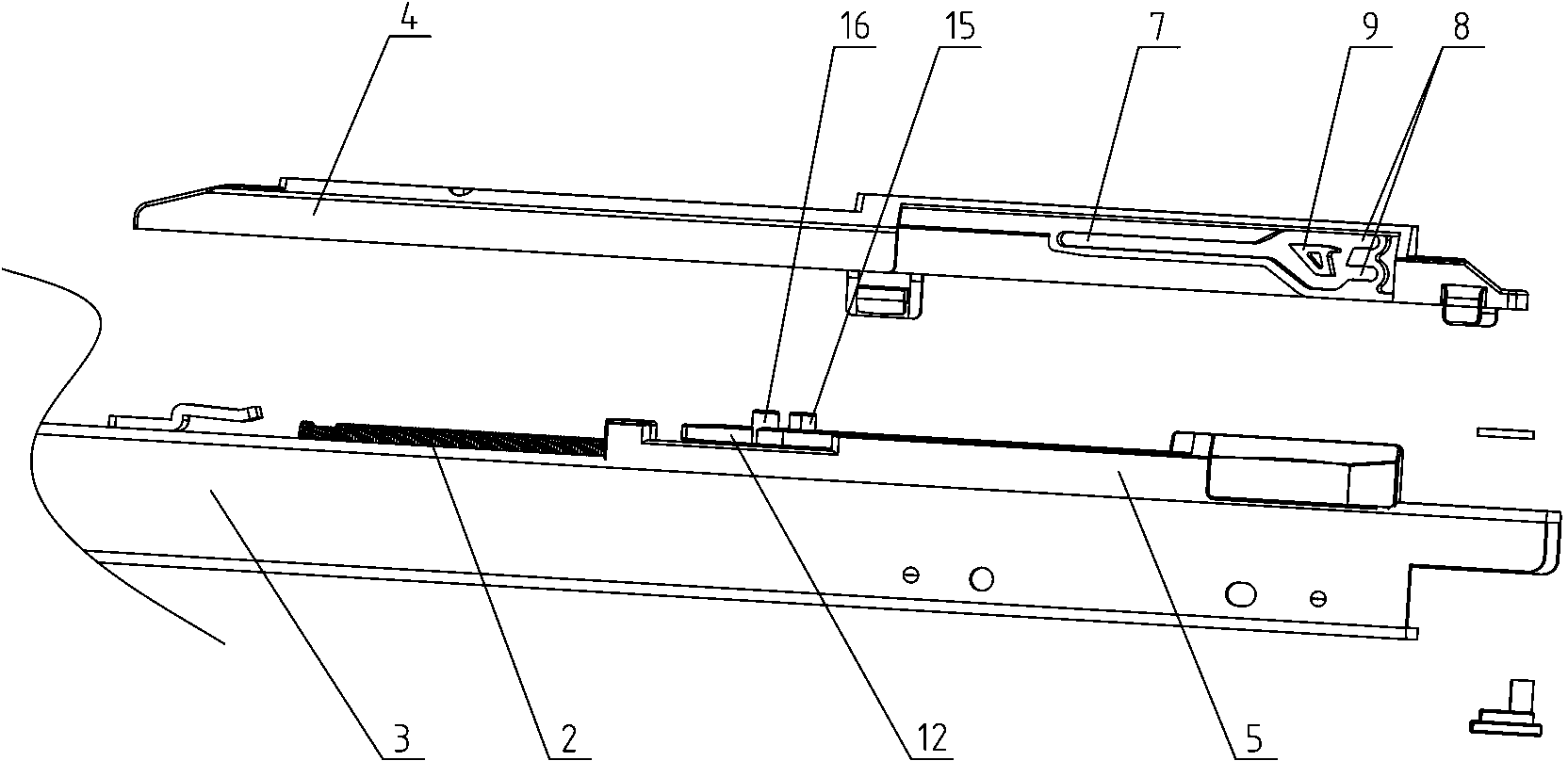

[0024] The present invention will be described in detail below in conjunction with accompanying drawing, as the first embodiment figure 1 , figure 2 and image 3 As shown, it includes a mounting plate 1 installed on the side panel of the cabinet and a rebound slide rail assembly installed on the drawer. The rebound slide rail assembly is adapted to be installed on the installation plate 1. The lower rail assembly 3 and the rebound seat 4, the lower rail assembly 3 is installed on the mounting plate 1 and connected with the rebound seat 4, the rebound slider 5 is slidably connected to the rebound seat 4, and one end of the elastic member 2 is fixed on the rebound seat 4, the other end of the elastic member 2 is fixed on the rebound slider 5. Wherein, the rebound slider 5 is embedded with a pendulum needle 6 connected to it in rotation, specifically shown as, figure 2 As shown, the rebound slider 5 is provided with a mounting groove 10 suitable for the embedding of the swi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap