Cutting assembly of stapler

A technology for staplers and components, which is applied in the fields of cutting components of circular staplers and curved staplers, linear cutting staplers, and stapler cutting components. Problems, achieve the effect of accelerating tissue healing, shortening operation time, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

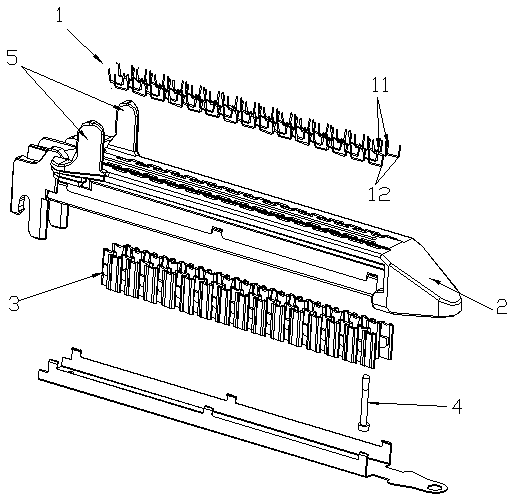

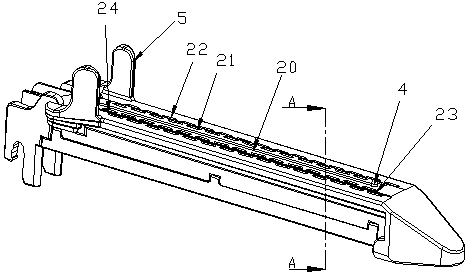

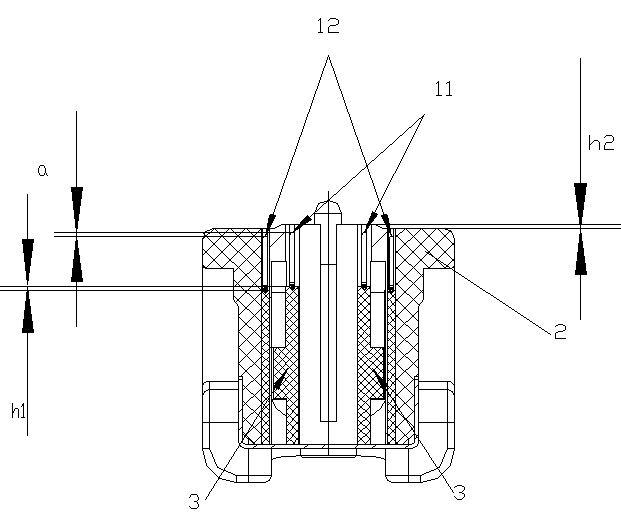

[0014] The stapler cutting assembly includes a staple cartridge 2, a staple pusher 3 installed in the staple cartridge 2 and a staple 1 pushed by the teeth of the staple pusher 3. The surface of the staple cartridge is provided with a pusher groove 20, and the surface of the staple cartridge is distributed For more than two rows of cartridge holes, the cartridge holes arranged close to the push knife groove 20 are the inner staple cartridge holes 21, and the staple cartridge holes arranged away from the push knife groove 20 are the outer staple cartridge holes 22. The staple 1 and the staple cartridge The holes 21, 22 are correspondingly distributed. As shown in the figure, the teeth for pushing the outer row of staples 12 are the outer row of teeth 32, and the teeth for pushing the inner row of staples 11 are the inner row of teeth 31, and the height of the inner row of teeth 31 is higher than that of the outer row. The tooth pieces 32, the height difference between the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com