A semi-synthetic catalytic cracking catalyst

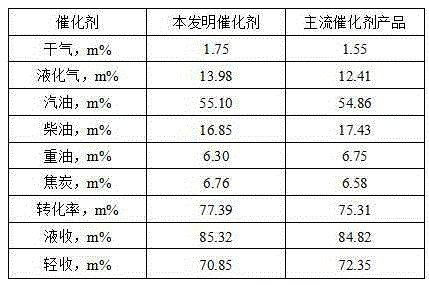

A catalytic cracking and catalyst technology, which is applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of lowering the quality of refined oil and low octane number of gasoline, and achieves low production costs and no increase in catalyst unit consumption , The effect of high product liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: The following steps are used to realize the present invention: First, Maoming kaolin is coarsely crushed to a particle size of 150 μm, mixed with chemical water, beaten, and dispersed evenly, then acidified by adding hydrochloric acid with a concentration of 35% for 20 minutes, and then adding rare earth solution ReCl 3 After reacting the solution and pseudo-boehmite for 30 minutes, heat up to 85°C and age for 30 minutes, then add aluminum sol and Y-type synthetic zeolite molecular sieve to beat together for 25 minutes, homogenize and spray dry, and the product obtained is roasted at 800°C and washed with water The finished product is obtained after drying; the dosage ratio is: 38 parts of Maoming kaolin, 30 parts of pseudo-boehmite, 12 parts of aluminum sol, 32 parts of molecular sieve, rare earth solution ReCl 3 0.15 parts of solution, 5 parts of hydrochloric acid.

[0016] Among them, the composition of Maoming kaolin is as follows: the content of kaoli...

Embodiment 2

[0022] Embodiment 2: The following steps are used to realize the present invention: First, Maoming kaolin is coarsely crushed to a particle size of 200 μm, mixed with chemical water, beaten, and dispersed evenly, then acidified with 25% hydrochloric acid for 30 minutes, and then added with rare earth solution ReCl 3 After reacting the solution and pseudo-boehmite for 20 minutes, heat up to 75°C and age for 45 minutes, then add aluminum sol and Y-type synthetic zeolite molecular sieve to beat together for 10 minutes, homogenize and spray dry, and the product obtained is roasted at 850°C and washed with water The finished product is obtained after drying; the dosage ratio is: 40 parts of Maoming kaolin, 28 parts of pseudoboehmite, 10 parts of aluminum sol, 40 parts of molecular sieve, rare earth solution ReCl 3 0.5 parts of solution, 4 parts of hydrochloric acid.

[0023] Among them, the composition of Maoming kaolin is as follows: the content of kaolinite is 91.77%, the element...

Embodiment 3

[0024] Embodiment 3: The following steps are used to realize the present invention: First, Maoming kaolin is coarsely crushed to a particle size of 100 μm, mixed with chemical water, beaten, and dispersed evenly, then acidified by adding hydrochloric acid with a concentration of 40% for 10 minutes, and then adding rare earth solution ReCl 3 After reacting the solution and pseudo-boehmite for 40 minutes, heat up to 60°C and age for 60 minutes, then add aluminum sol and Y-type synthetic zeolite molecular sieve to beat together for 0 minutes, homogenize and spray dry, and the obtained product is roasted at 700°C and washed with water The finished product is obtained after drying; the dosage ratio is: 30 parts of Maoming kaolin, 25 parts of pseudo-boehmite, 6 parts of aluminum sol, 30 parts of molecular sieve, rare earth solution ReCl 3 Solution 0.05 parts, hydrochloric acid 2.5 parts.

[0025] Among them, the composition of Maoming kaolin is as follows: the content of kaolinite i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com