Cooling water circulation device for condensation point instrument

A technology of cooling water circulation and condensation point instrument, which is applied in heating or cooling equipment, chemical instruments and methods, laboratory appliances, etc., can solve the problems of artificially collecting water sources, occupying a large space, and manpower handling, etc., so as to improve the utilization rate of water sources , low cost and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

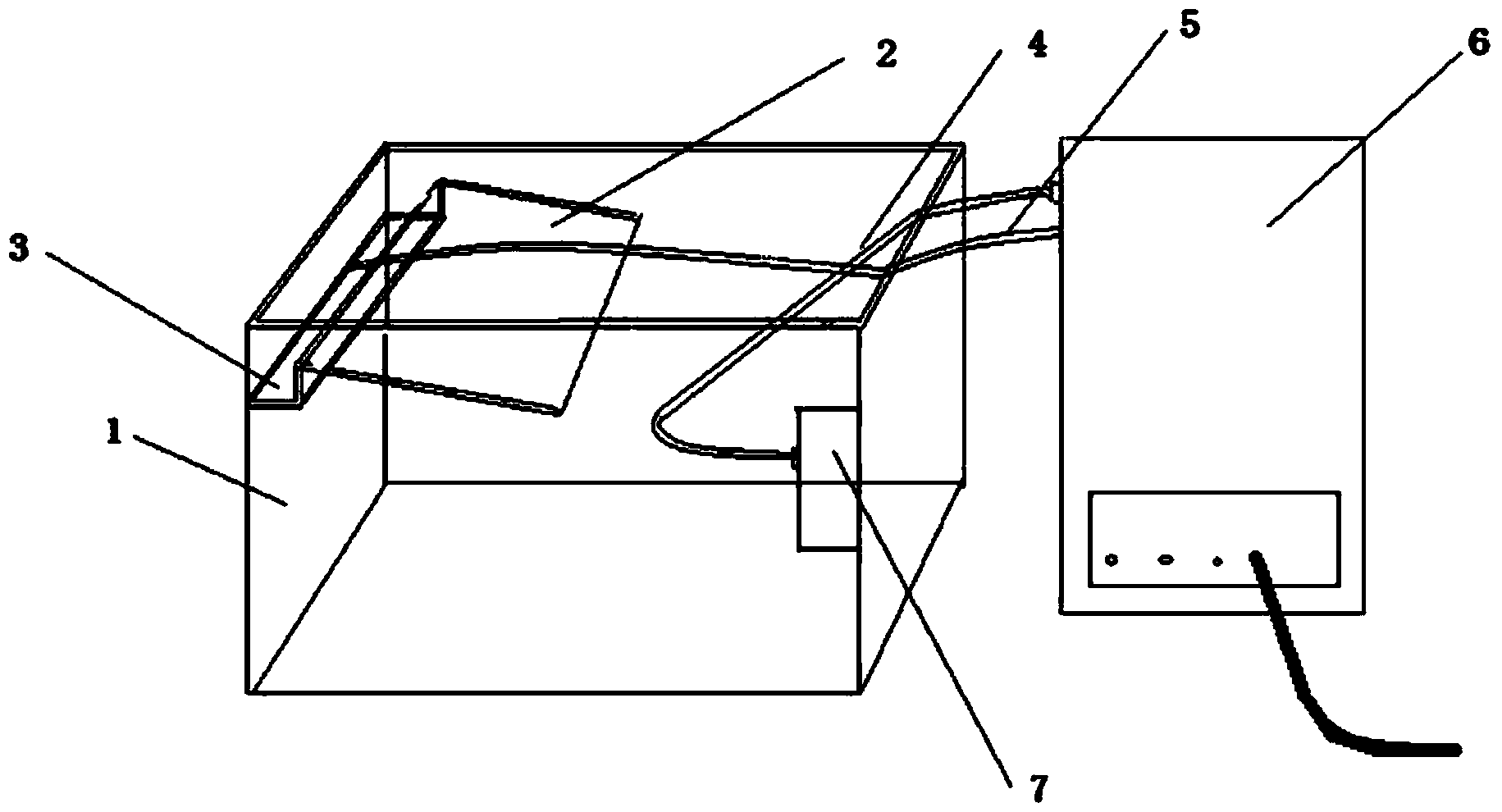

[0020] Such as figure 1 Shown: a cooling water circulation device designed for a freezing point instrument, including a reservoir 1, an auxiliary heat dissipation surface 2, a water storage groove 3, a centrifugal water pump 7, and a freezing point instrument 6; the auxiliary heat dissipation surface 2 is placed obliquely Inside the water storage tank 1, the upper edge of the water storage groove 3 is connected with the auxiliary cooling surface 2, and the lower edge of the water storage groove 3 is connected with the water storage tank 3; the centrifugal water pump 7 is connected with the condensation Point instrument 6 is connected by water inlet pipe 4; Described water inlet pipe 4 one ends connect the water outlet of centrifugal water pump 7, the other end connects the water inlet of coagulation point instrument 6, described outlet pipe 5 one ends and the outlet of coagulation point instrument 6 The water ports are connected, and the other end is fixed at the water storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com