Automatic carton bonding device

A carton, automatic technology, used in packaging, papermaking, transportation and packaging, etc., can solve the problems of inconvenient production, human hand injury, lack of pertinence, etc., to save working time, prevent damage, and drive smooth and noiseless. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

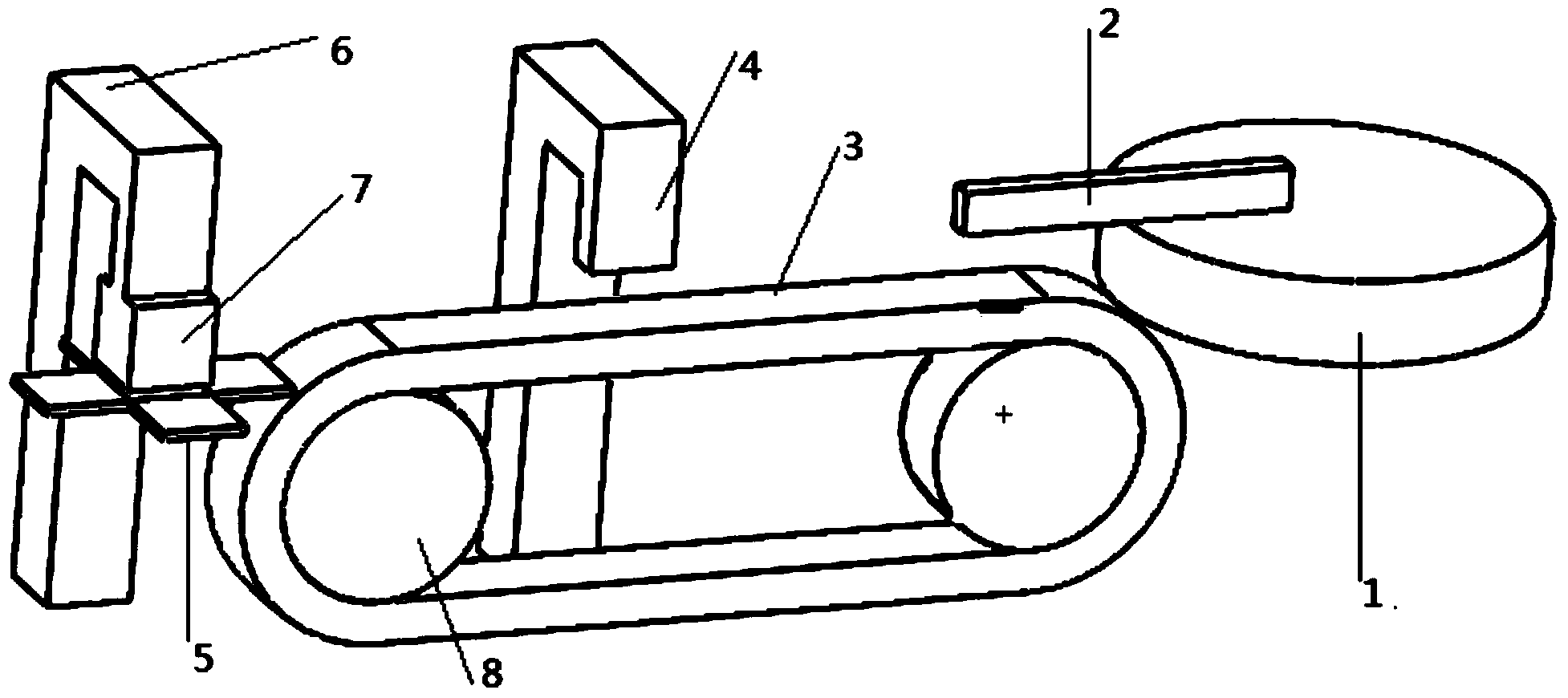

[0008] Such as figure 1 As shown, an automatic carton bonding device includes a rotary table 1, a baffle plate 2, a belt 3, a brush 4, a plate sticking table 5, a rocker arm 6, a solid block 7, a pulley 8, and the baffle plate 2 is fixed on the rotary table 1, there is a certain gap between the baffle plate 2 and the upper surface of the rotary table 1, the belt 3 is installed on the pulley 8, the brush 4 is installed above the belt 3, the sticking plate 5 is set at one end of the belt 3, and the solid block 7 is set on the sticking plate The top of the table 5 and the solid block 7 are installed on the rocker 6 , and the rocker 6 is also arranged on one end of the belt 3 .

[0009] When the device is working, the hard cardboard passes through the rotation of the rotary table 1 and is blocked by the baffle plate 2, then enters the belt 3 for transmission, and the brush 4 applies glue to the part of the paper that needs to be glued, and then is transported by the belt 3 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com